Thermal insulation sheet and method of manufacturing the same

A technology of thermal insulation board and thermal insulation material, applied in chemical instruments and methods, building structure, building components, etc., can solve the problems of low thermal insulation efficiency, unsuitability, weak fire resistance of synthetic resin, etc., to reduce energy loss and reduce drying. The effect of time, wide interior space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0017] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those skilled in the art can easily understand and reproduce the present invention.

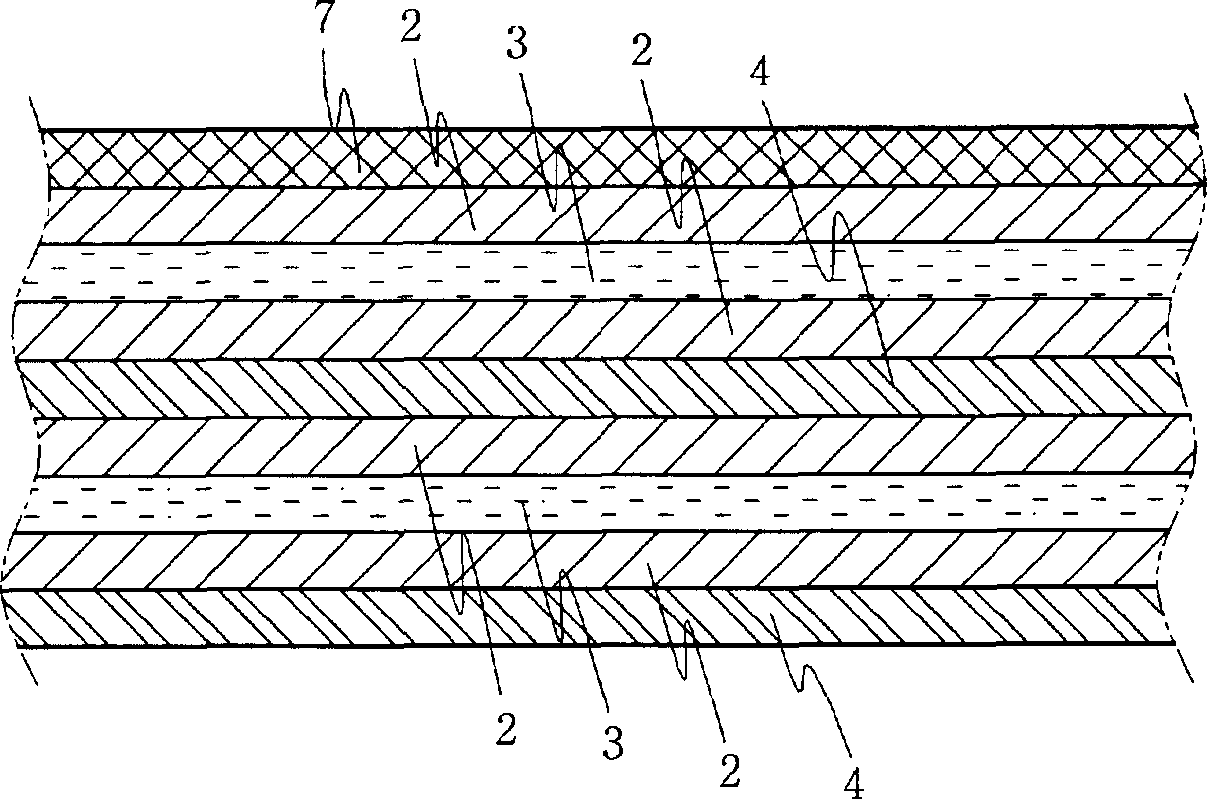

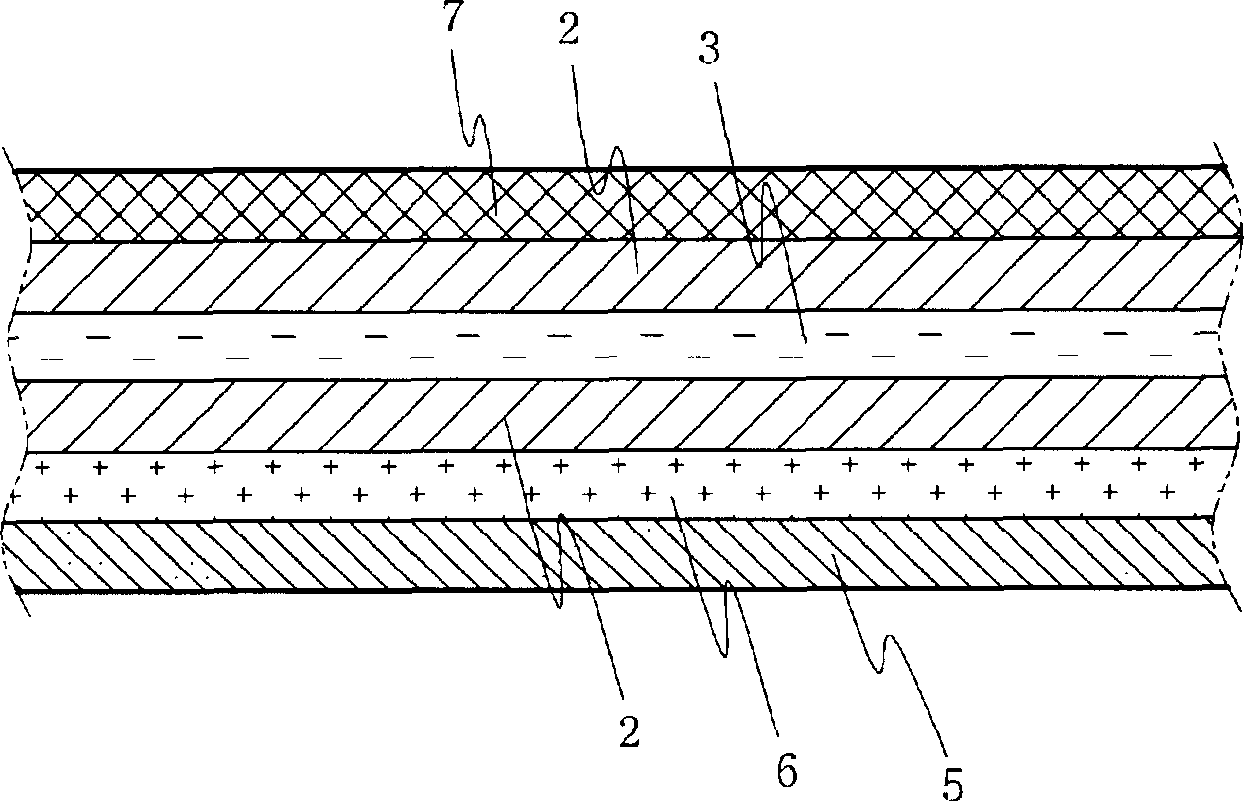

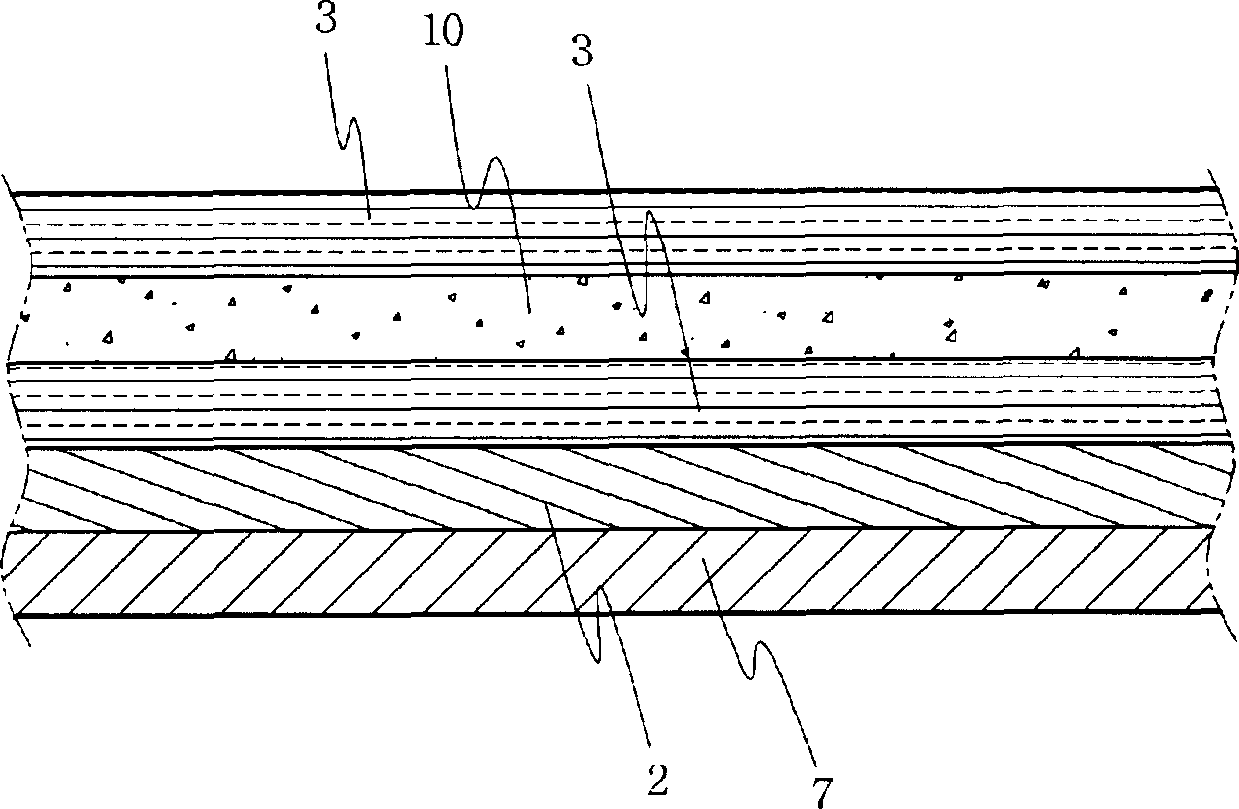

[0018] Figure 4 is a perspective view of a thermal insulation panel according to the present invention, with a part of the thermal insulation panel cut away. Fig. 5 is a structural view showing the internal structure of the aluminum foil used in the present invention. Figure 6 is a schematic cross-sectional view of an insulating panel according to the present invention, Figure 7 is a flowchart schematically showing the manufacturing process of the insulating panel according to the present invention.

[0019] Such as Figure 4 As shown (which is a perspective view of the heat insulation board of the present invention, in which a part of the heat insulation board is cut off), the heat insulation board includes bulk heat insulation material 3 , aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com