Roller of composite polymer material

A composite material and polymer technology, applied in the field of rollers formed by new polymer composite materials, can solve the problems of low friction coefficient, easy corrosion of rollers, heavy weight, etc., and achieve long life, saving steel raw materials, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

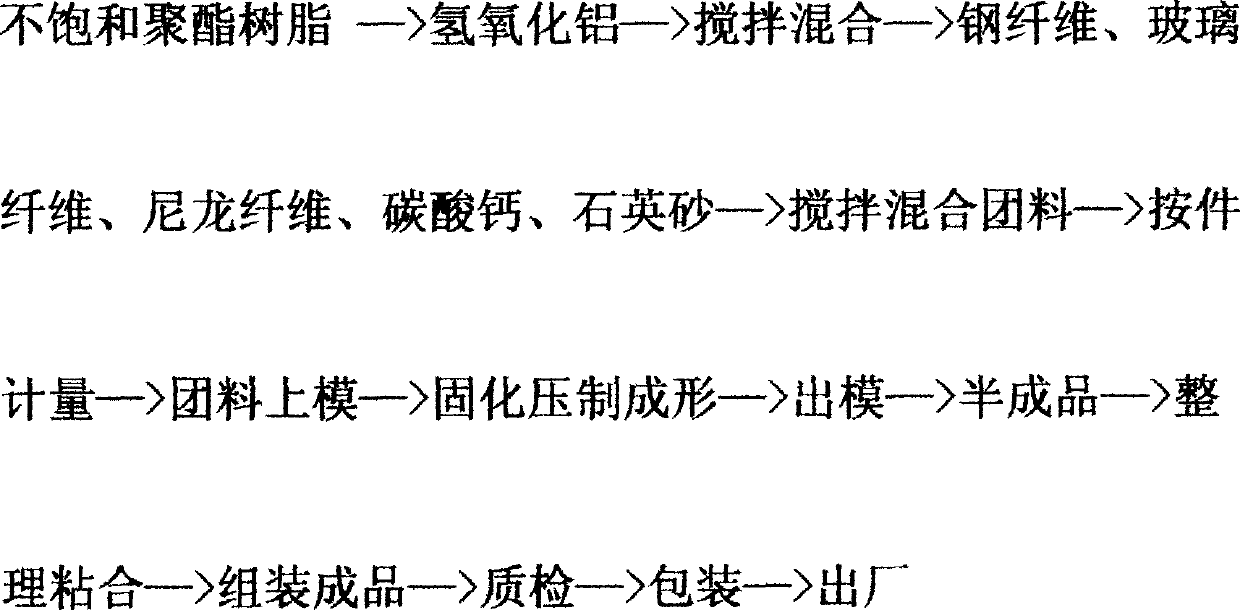

[0009] Firstly, the raw materials are screened and weighed. They are mixed with unsaturated polyester resin and aluminum hydroxide at room temperature for ten minutes, and then mixed with steel fiber, glass fiber, nylon fiber, graphite, calcium carbonate, and quartz sand to form an agglomerate. , And then measure the material according to the size of the piece. The upper mold of the bulk material is at 150 degrees Celsius, and the mold is cured for five minutes (long rollers above 500 mm need to be lined with thin-walled steel pipes), and then the semi-finished parts are arranged and bonded, and assembled to the finished product After quality inspection, packaging and leaving the factory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com