Rare-earth-mixed barium borophosphate flashing luminous material, its preparing method and use

A flashing luminescence and barium borophosphate technology, which is applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of low luminous efficiency and easy deliquescence, and achieve the effect of simple equipment, low cost and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

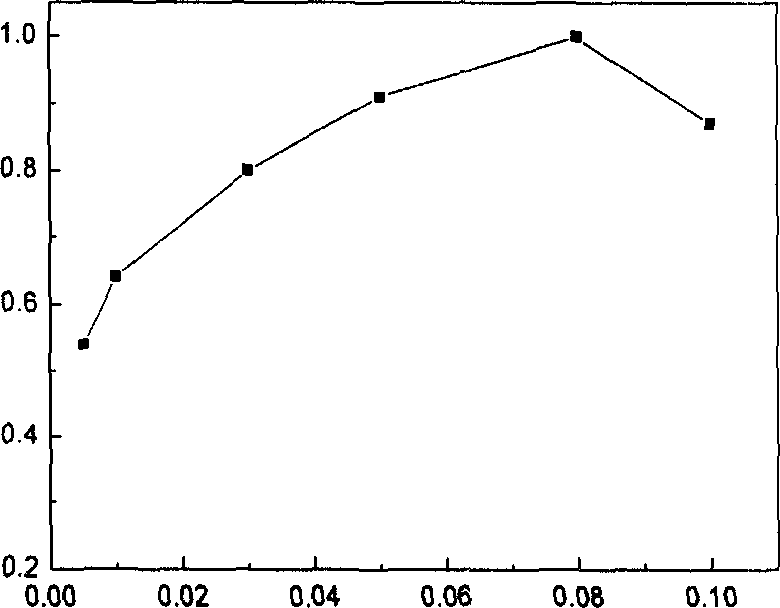

[0012] Press Ba 2.985 Eu 0.015 BP 3 o 12 The stoichiometric ratio is matched. BaCO 3 and Eu 2 o 3 Mix thoroughly and evenly at a molar ratio of 10:1, and set aside. Weigh the above BaCO 3 and Eu 2 o 3 0.064g of the mixture, another BaCO 3 1.119g, H 3 BO 3 0.124g, NH 4 h 2 PO 4 0.69g, fully ground and mixed in an agate mortar and placed on Al 2 o 3 In the crucible, after capping, put Fe-Cr-Al wire into the muffle furnace as the heating element, heat up at a heating rate of 5 °C / min, and burn at 300 °C for 5 hours; after the pre-fired product is naturally cooled, it is Take it out, fully grind and mix it evenly, and shape it into a Φ20 sheet on a tablet machine, with a pressure of 170Mpa, and keep the pressure for 30s; finally, put the formed sheet on the Al 2 o 3 In the crucible, after being covered, it is put into a muffle furnace with Fe-Cr-Al wire as the heating element and burned at a heating rate of 5°C / min. The burning temperature is 1000°C and the reac...

Embodiment 2

[0014] Press Ba 2.97 Eu 0.03 BP 3 o 12 The stoichiometric ratio is matched. BaCO 3 and Eu 2 o 3 Mix thoroughly and evenly at a molar ratio of 10:1, and set aside. Weigh the above BaCO 3 and Eu 2 o 3 0.129g of the mixture, another take BaCO 3 1.054g, H 3 BO 3 0.124g, NH 4 h 2 PO 4 0.69g, fully ground and mixed in an agate mortar and placed on Al 2 o 3 In the crucible, after capping, put Fe-Cr-Al wire into the muffle furnace as the heating element, heat up at a heating rate of 5 °C / min, and burn at 300 °C for 5 hours; after the pre-fired product is naturally cooled, it is Take it out, fully grind and mix it evenly, and shape it into a Φ20 flake on a tablet press, with a pressure of 170Mpa, and keep the pressure for 30s; put the formed flake in a smaller capacity Al 2 o 3 Put the crucible into the small-capacity crucible after being covered, put graphite or carbon into the gap between the large-capacity crucible and the small-capacity crucible, and cover the ou...

Embodiment 3

[0016] Press Ba 2.91 Eu 0.09 BP 3 o 12 The stoichiometric ratio is matched. BaCO 3 and Eu 2 o 3 Mix thoroughly and evenly at a molar ratio of 10:1, and set aside. Weigh the above BaCO 3 and Eu 2 o 3 0.387g of the mixture, another take BaCO 3 0.793g, H 3 BO 3 0.124g, NH 4 h 2 PO 4 0.69g. The rest is the same as in Example 2, and the white powder obtained after grinding is the required X-ray-excited scintillating luminescent material, and the luminous intensity is 1.47 times that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com