Complete equipment for decreasing push, increasing pressure and desulfurizing and desulfurization thereof

A complete set of equipment and desulfurization process technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of amine liquid not settling down, affecting mass transfer efficiency, shutdown and cleaning, etc., to achieve small equipment investment and desulfurization Good effect, high boosting and pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

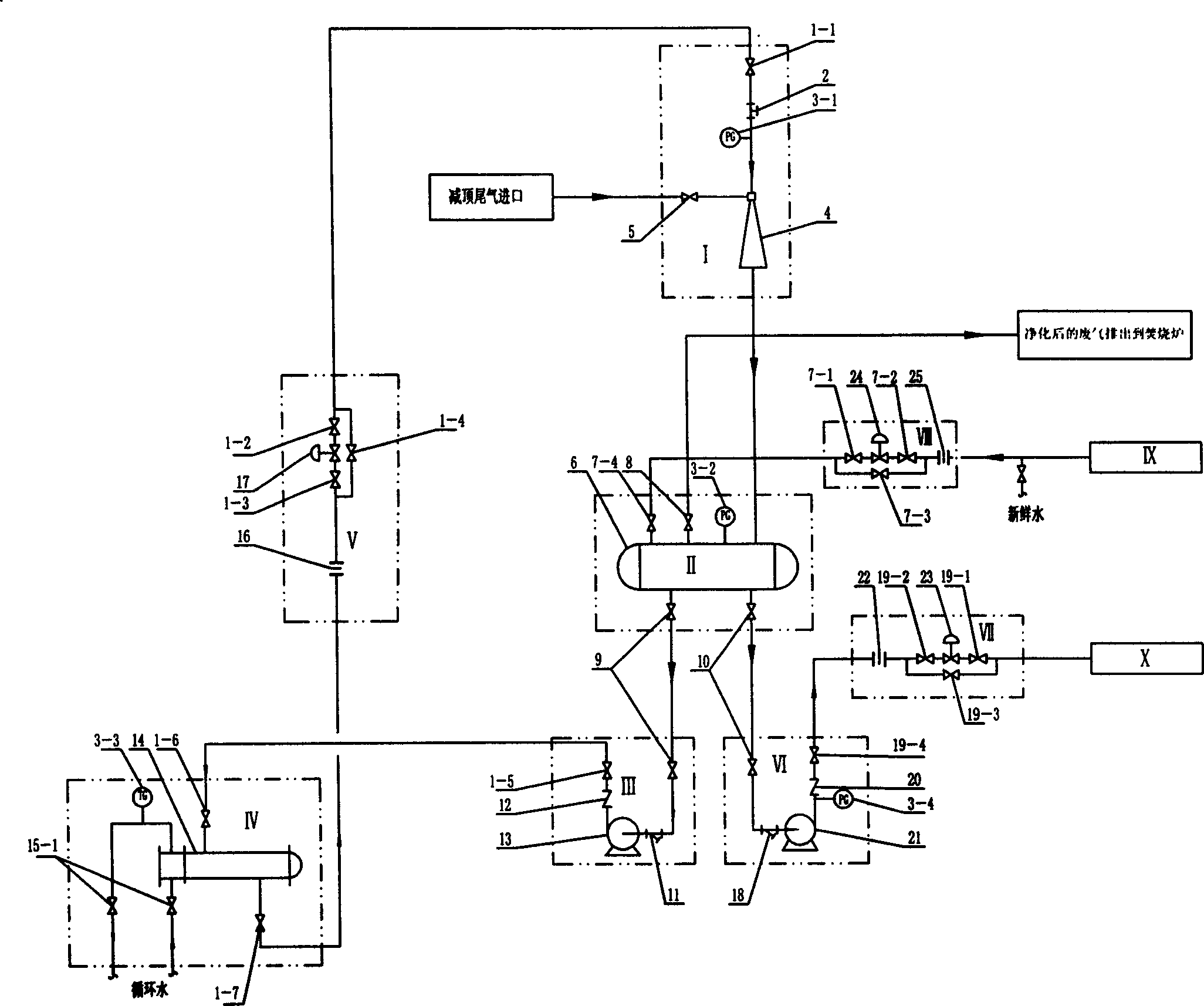

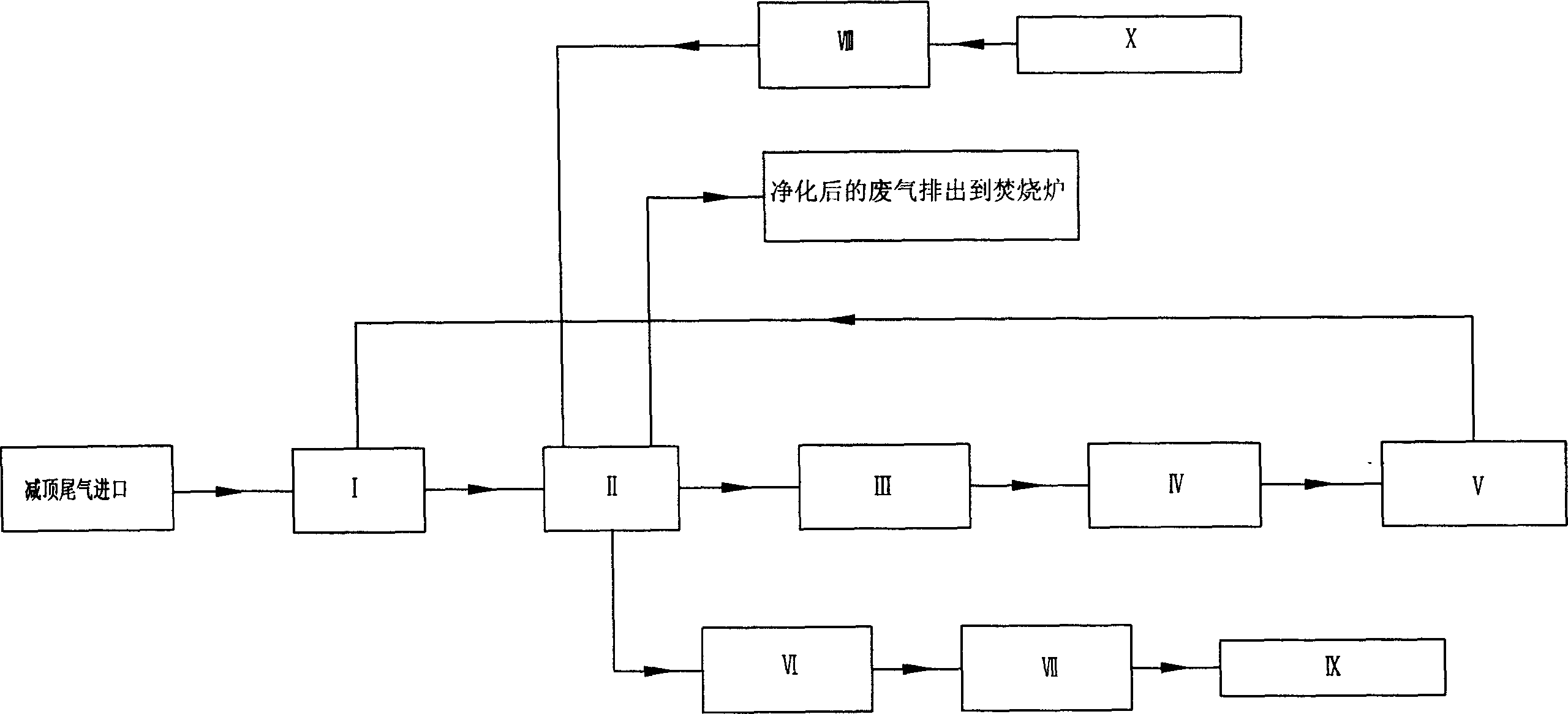

[0028] Examples of top-reducing pressurized desulfurization complete sets of equipment:

[0029] see figure 1 , the roof-reducing pressurized desulfurization complete set of equipment in the present invention is composed of a pressurized injection device I, a solution tank II, a circulation pump device III, a rich liquid pump device VI, a cooler device IV, an outlet flow control device VII, and a working fluid flow control device. Device V, liquid inlet flow control device VIII, methyldiethanolamine rich liquid regeneration device IX and methyldiethanolamine solution inlet device X are composed.

[0030] The boost injection device 1 comprises a first manual valve 1-1, a first filter 2, a first pressure transmitter 3-1, a boost injector 4 and a second manual valve 5, and the first manual valve 1-1 , the first filter 2, the first pressure transmitter 3-1 and the booster injector 4 are connected in sequence through pipelines, and one end of the second manual valve 5 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com