Protective film for axles

A technology of protective film and axle, applied in the direction of film/flaky adhesives, layered products, transportation and packaging, etc., can solve the problems of complicated inspection, difficult to remove paint coating, harmfulness, etc., and achieve the goal of reducing downtime Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Method of Coating Type 2 or Type 3 Axles

[0065] Axle generally refers to the straight portion from the axle and the terminal portion constituting the fillet of the axle. When cracks develop on the axle, the cracks appear first on these rims.

[0066] First, a layer of aluminum adhesive is applied to the rim of the axle. This layer is applied with a side that has an acrylic adhesive, allowing it to adhere to the rim.

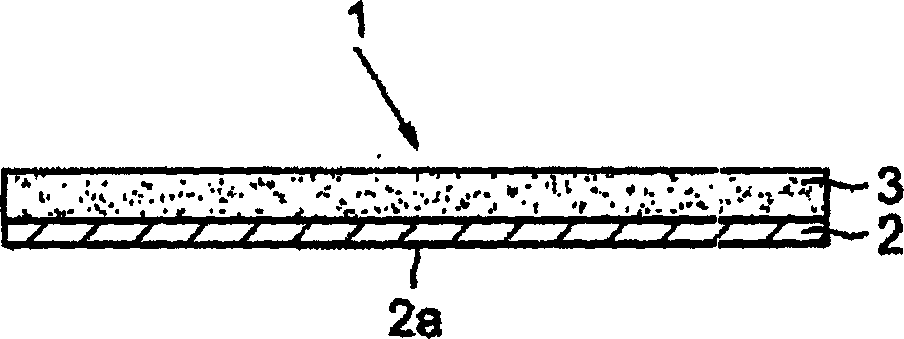

[0067] followed by figure 1 The films shown are applied to the entire axle, ie to the straight portion of the axle and to the rim. Thus, the rim has two successively applied layers of aluminum adhesive.

[0068] After the type 2 or type 3 hub is completely covered by the film 1, adhesive strips are attached longitudinally on the edges of the butyl mastic layer 3, so that the terminal portions of the film 1 are attached. With such a connection, the membrane 1 will not fall off during use. It is also possible to form the film 1 directly on...

Embodiment 2

[0070] Example 2: Method of coating type 1 axles

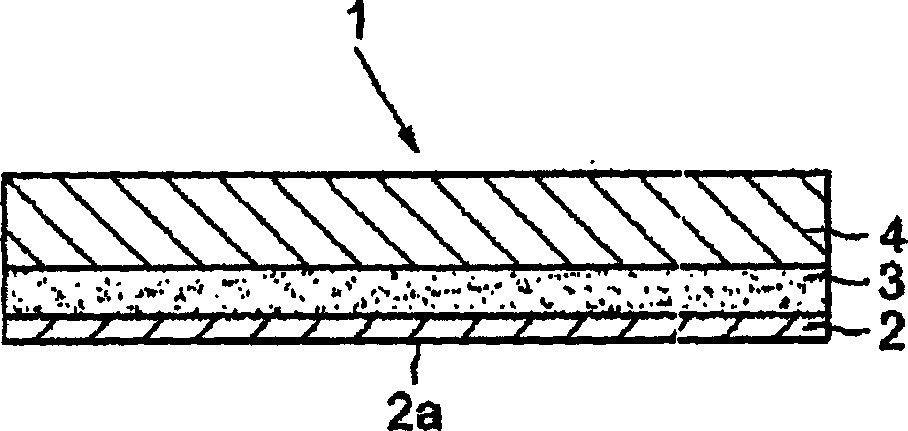

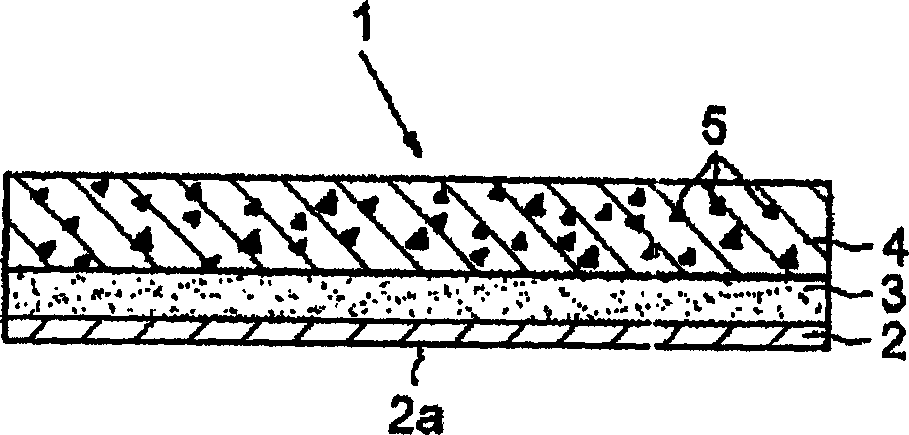

[0071] In the same way as in the method of coating type 2 or type 3 axles, a layer of aluminum adhesive is first applied to the rim and then as figure 2 or image 3 Film 1 was applied to the entire axle as shown.

[0072] Thus, the rim has two successively applied layers of aluminum adhesive. After the type 1 axle is completely covered by the membrane 1 , the adhesive is applied to the edge of the polyurethane layer 4 . The adhesive was cold applied manually using a two-component spray gun, joining the terminal portions of the film. The adhesive composed of polyurethane can prevent the film 1 wrapped on the axle from falling off during the use. By applying the different layers one after the other, it is possible to arrange the membrane 1 directly on the axle.

[0073] During inspection of the condition of the axle by magnetic or ultrasonic testing, a biodegradable solvent that dissolves the adhesive may be applied. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com