Composite spining module

A composite spinning and assembly technology, which is applied in the direction of feeding solution to the spinneret, etc., can solve the problems that the fiber cannot produce ultra-fine fibers, the quality of the fabric is poor, and the energy consumption increases, so as to reduce equipment and manpower investment and improve health. Bone and stiffness, the effect of shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

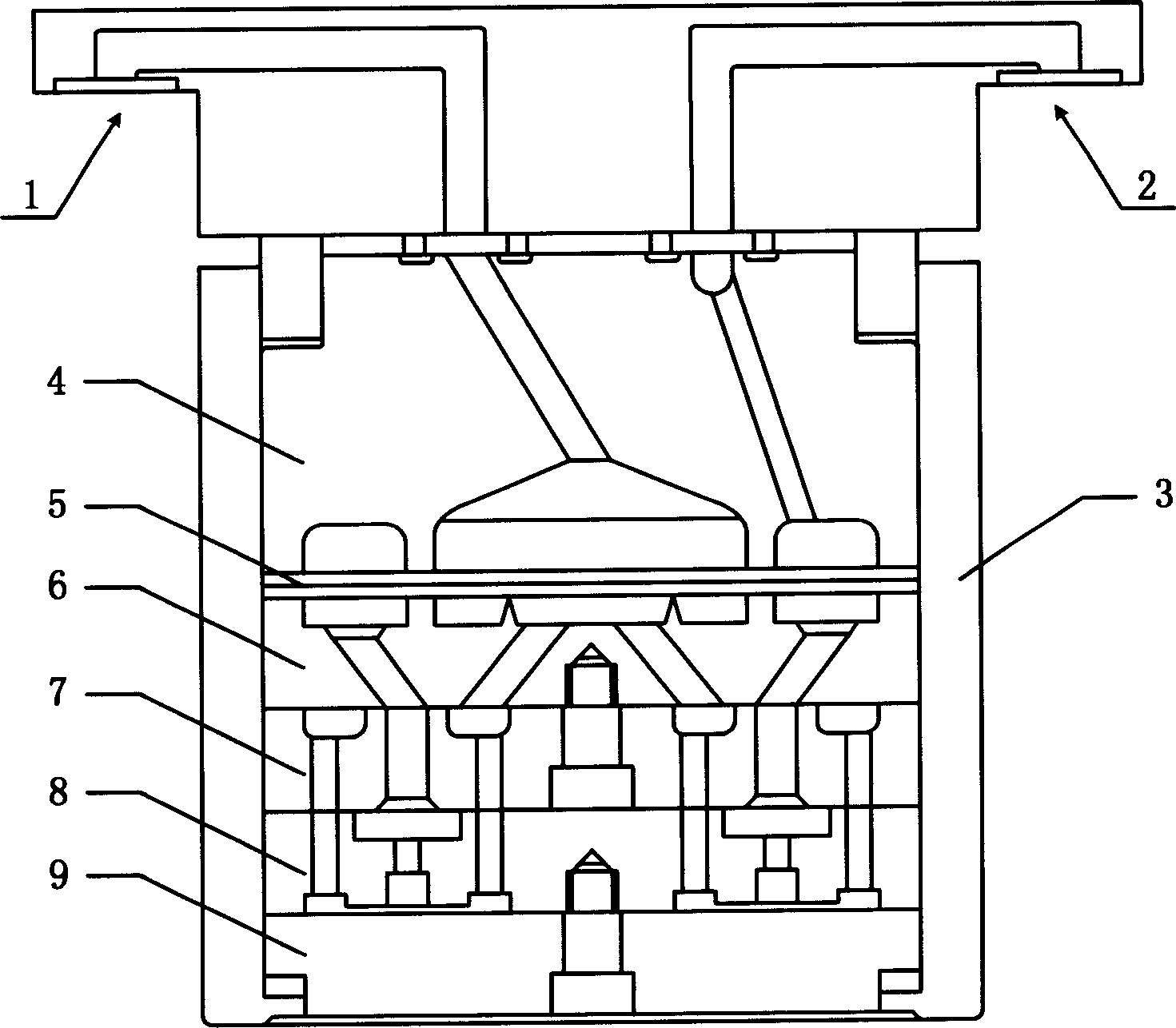

Embodiment 1

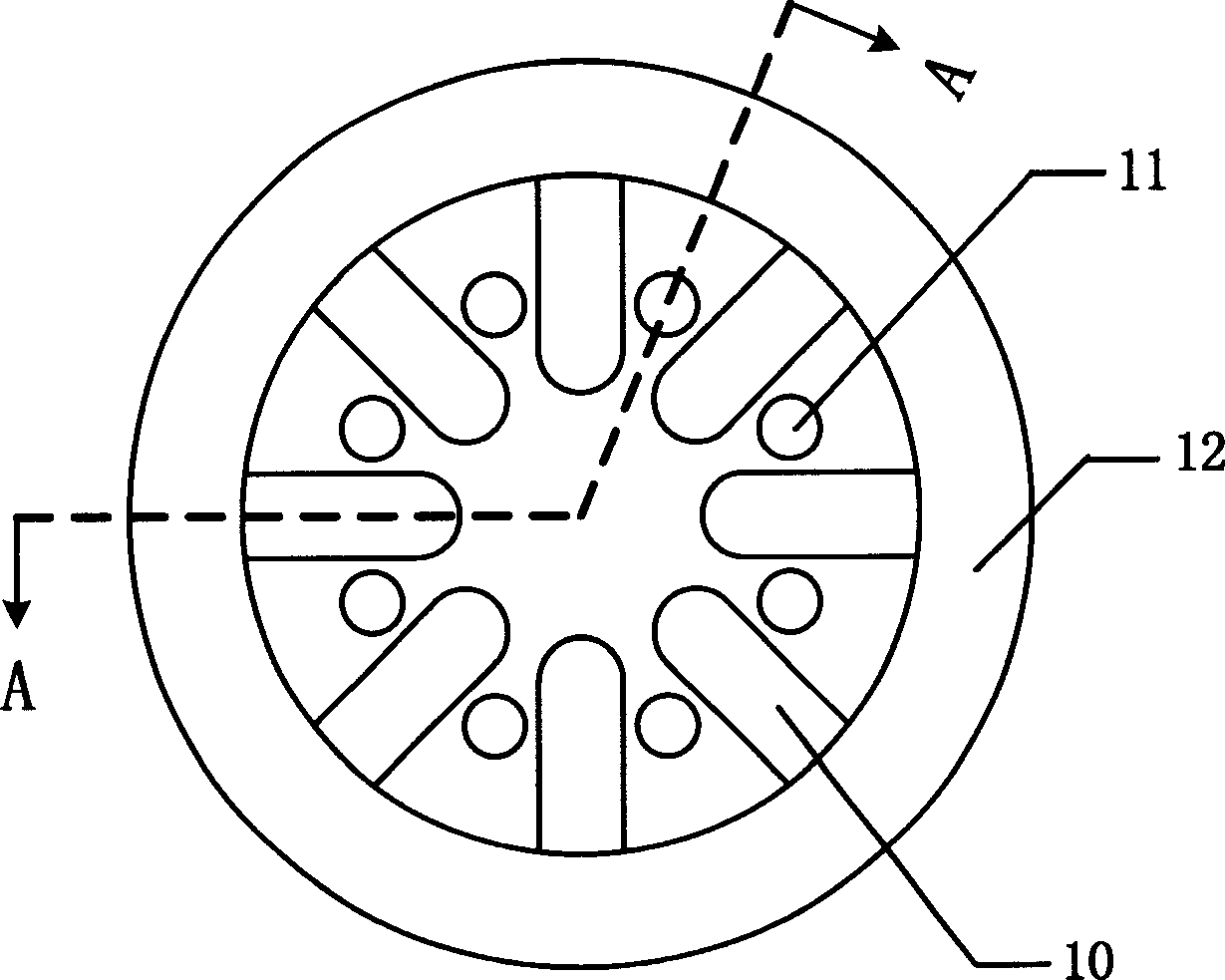

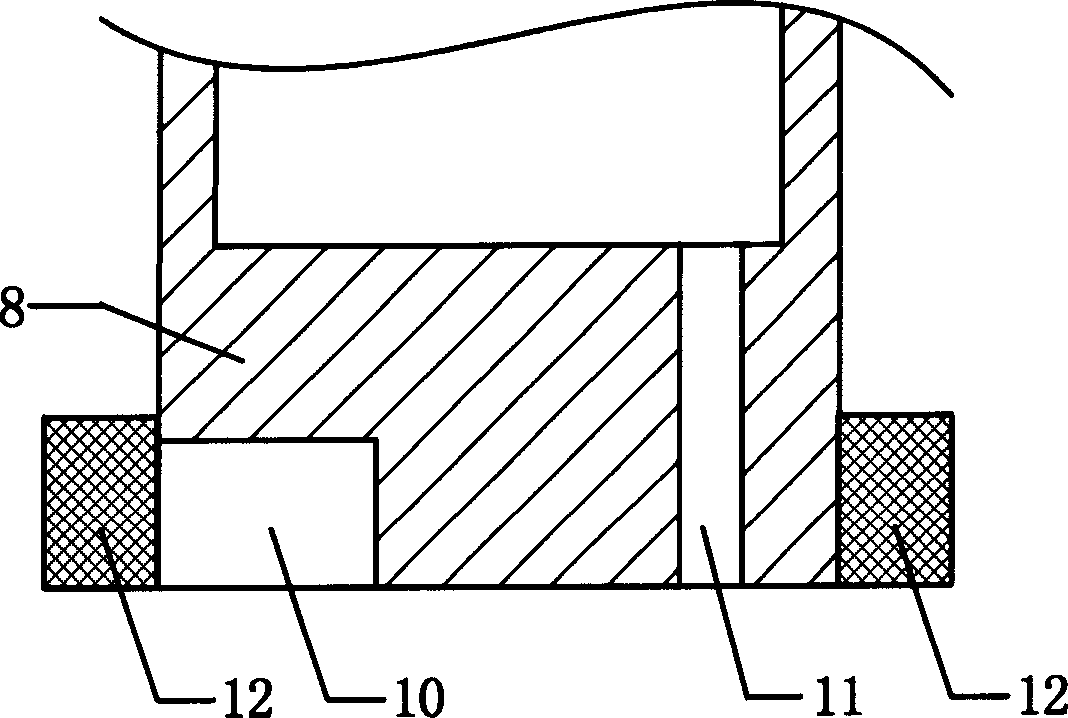

[0032] There are 72 grooves such as: figure 2 and image 3 As shown in the bosses, there are two melt channels inside each boss, and 72 bosses are distributed in a ring, of which 18 bosses are located in the inner ring (center position) of the composite plate, and the other 54 bosses are They are located in the outer two circles respectively. A closed metal ring is arranged on the outer rings of the 18 bosses at the center of the composite plate, so that only one kind of melt can flow through the 18 bosses. Then the composite plate and spinneret, distribution plate and other parts are packed into a complete composite spinning assembly, and the two polymer melts of PET (polyester) and PA-6 (polyamide 6) are as follows Process conditions for spinning: PET melt can flow through all bosses, while PA-6 melt can only flow through 54 bosses that are not isolated, PET melt temperature (main box temperature) 286 ~ 296 ° C , PA-6 melt temperature 258 ~ 275 ℃, PET melt extrusion volu...

Embodiment 2

[0035] There are 72 grooves such as: figure 2 and image 3 As shown in the bosses, there are two melt channels inside each boss, and 72 bosses are distributed in a ring, of which 18 bosses are located in the inner ring (center position) of the composite plate, and the other 54 bosses are They are located in the outer two circles respectively. Randomly select 18 bosses from the 72 bosses, and add a metal ring around them. These metal rings isolate these 18 bosses from the other 54 bosses. The interior of these 18 bosses is Only one kind of melt is allowed to flow through, and the spinneret hole above the spinneret below it is designed as a special-shaped hole. Then the composite plate and spinneret, distribution plate and other parts are packed into a complete composite spinning assembly, and the two polymer melts of PET (polyester) and PA-6 (polyamide 6) are as follows Process conditions for spinning: PET melt can flow through all bosses, while PA-6 melt can only flow thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com