Semiconductor luminescent element composition

A technology of light-emitting elements and semiconductors, which is applied in the direction of semiconductor devices, electrical components, and electric solid-state devices, and can solve problems such as low acceptance, high prices, and reduced product reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

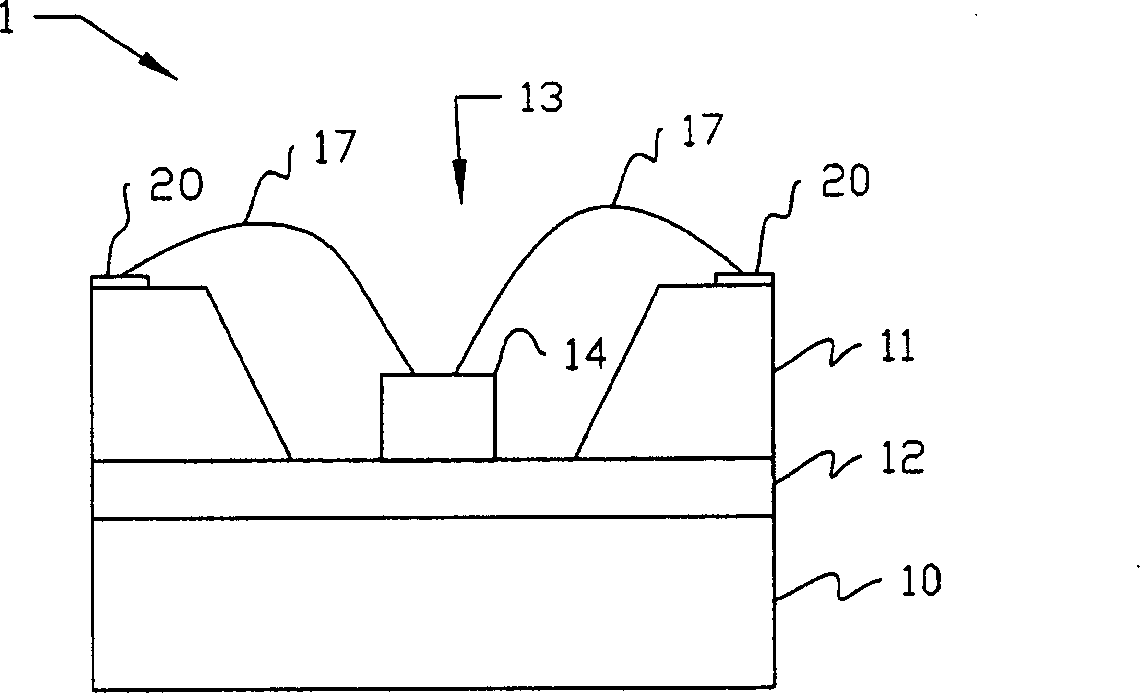

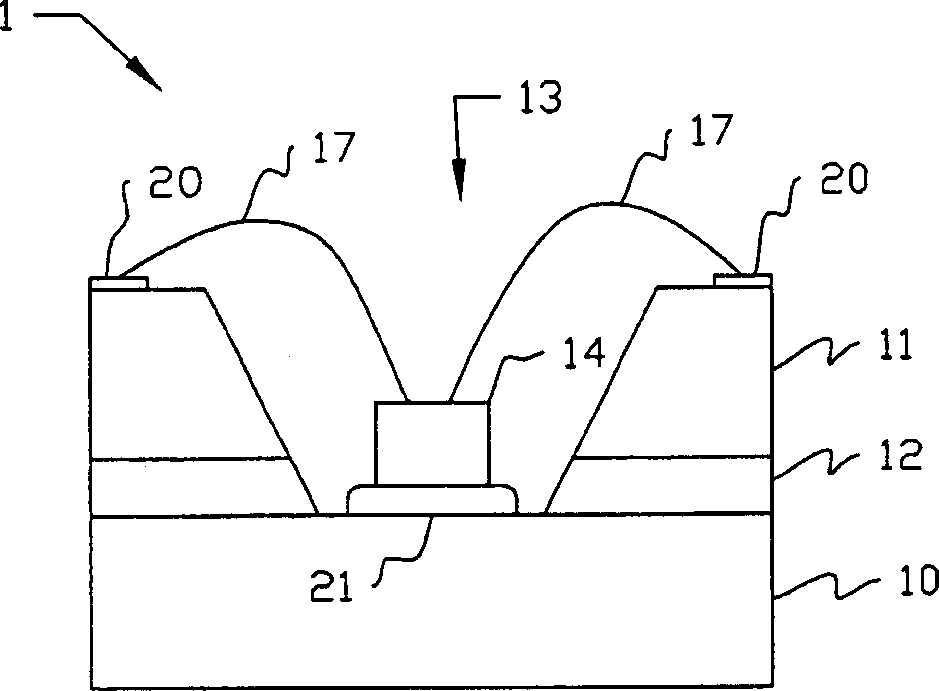

[0029] Figure 1a and 1b A structural diagram showing a semiconductor light emitting element composition 1 according to an embodiment of the present invention. The meanings of each mark are as follows, 1 indicates the composition of the semiconductor light-emitting element; 10 indicates the composite material substrate; 11 indicates the circuit layout carrier; 12 indicates the bonding structure; 13 indicates the recessed space; 14 indicates the semiconductor light-emitting element; 17 indicates the wire; 20 Indicates an electrical contact. In addition, the same elements in the following other drawings will be marked with the same symbols, and will not be repeated, and will be described first.

[0030] Firstly, after the recessed space 13 is formed on the circuit layout carrier 11 , the circuit layout carrier 11 and the composite material substrate 10 are combined with the bonding structure 12 . Next, the semiconductor light emitting element 14 is fixed in the recessed space ...

no. 2 example

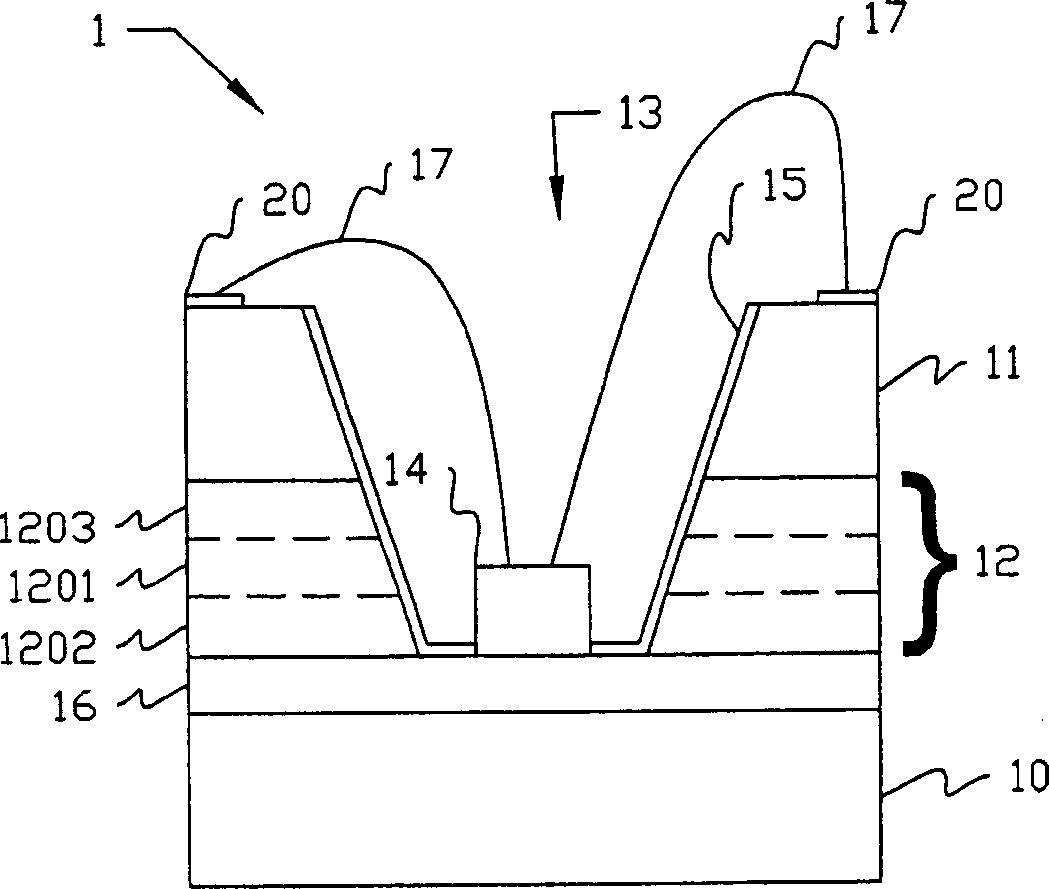

[0039] figure 2 A structural diagram showing a semiconductor light emitting element composition 1 according to another embodiment of the present invention. Wherein, mark 1201 represents a soft viscous material layer; 1202 and 1203 represent a reaction layer; 15 represents a reflection layer; 16 represents a planarization layer;

[0040] As described in the first embodiment, the semiconductor light emitting element 14 of the present invention is combined with the circuit layout carrier 11 via the adhesive structure 12 . In addition, in addition to using the above-mentioned soft adhesive material, other materials can be used in combination to further improve the adhesive properties of the adhesive structure 12 . Such as figure 2 As shown, the adhesive structure 12 includes a soft adhesive material layer 1201 , and reactive layers 1202 and / or 1203 . The soft viscous material layer 1201 is the material as described in the first embodiment. The reaction layers 1202 and 1203 a...

no. 3 example

[0044] Figure 3a-3d A structural diagram showing a semiconductor light emitting element composition 1 according to another embodiment of the present invention. The mark 18 represents the light-transmitting material; 18a represents the filling material; 19 represents the wavelength conversion material.

[0045] The positive and negative electrodes of the semiconductor light emitting element 14 disclosed in the above embodiments are located on the same side, and the positive and negative electrodes are connected to the electrical contact 20 by wires 17 . However, the semiconductor light emitting device 14 in the present invention can also be a flip chip (Flip Chip) structure, that is, the positive and negative electrodes on the same side of the semiconductor light emitting device 14 are all facing the direction of the composite material substrate 10 . If the semiconductor light-emitting element 14 is configured in a flip-chip manner, the wire 17 is not needed, but the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com