Method for brewing sauce

A soy sauce and pre-fermentation technology, applied in food preparation, application, food science, etc., can solve the problems of single production strain, poor product flavor and grade, backward production technology, etc., and achieve high production efficiency, good internal quality, and production short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

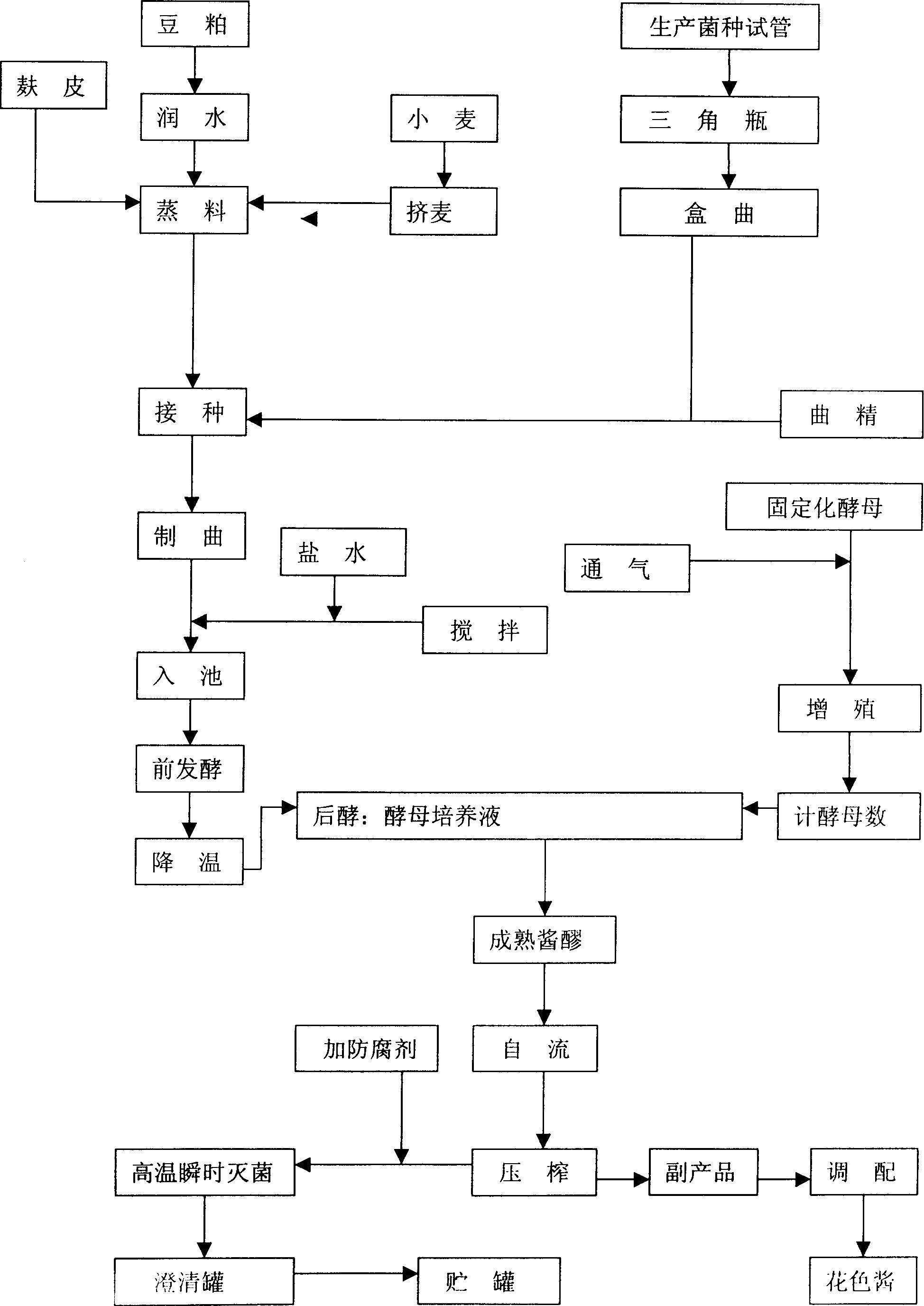

[0107] Soy sauce brewing method of the present invention is as follows:

[0108] Including ingredients, steaming, koji making, pre-fermentation and yeast culture, post-fermentation and pressing for yeast aroma enhancement, oil extraction and clarification of sediment until the product is obtained.

[0109] The main process parameters are controlled as follows:

[0110] 1. Raw material ratio: soybean meal: fried wheat = 6:4

[0111] 2. Wetting temperature: 100±1℃

[0112] 3. Moisturizing amount: 1.1 times the mass of soybean meal

[0113] 4. Moisturizing time: 40min

[0114] 5. Steam pressure: 0.18Mpa

[0115] 6. Pressure holding time: 14min

[0116] 7. Steaming time: 50min

[0117] 8. Inoculation temperature: 35±10℃

[0118] 9. Inoculation amount: 0.3‰

[0119] 10. Cultivation time: 40h

[0120] 11. Cultivation temperature: 33±1℃

[0121] 12. Salt water concentration: 12.5°Be

[0122] 13. Salt water temperature: 50±2℃

[0123] 14. The amount of salt water: 2.6 time...

Embodiment 2

[0194] The main process control is as follows, and others are carried out according to conventional processes.

[0195] Fermentation is divided into pre-fermentation and post-fermentation. Pre-fermentation adopts low-salt solid-state high-temperature fermentation method, and post-fermentation adopts high-salt dilute state low-temperature fermentation method, and post-fermentation is added with soy sauce for aroma enhancement. The amount of yeast added is controlled as follows: 5 x 10 ml of moromi 6 yeast cell count.

[0196] The ingredients are defatted soybeans and wheat.

[0197] The fermentation control process parameters are:

[0198] Pre-fermentation temperature: 44±1°C, post-fermentation temperature: 29±1°C;

[0199] Pre-fermentation water bath: 47±1°C, post-fermentation water bath: 33±1°C;

[0200] Days of pre-fermentation: 20 days, days of post-fermentation: 11 days.

[0201] Wherein, the weight ratio of Saccharomyces rouxii, Torulopsis globosa and Japanese yeast ...

Embodiment 3

[0208] The main process control is as follows, and others are carried out according to conventional processes.

[0209] Fermentation is divided into pre-fermentation and post-fermentation. Pre-fermentation adopts low-salt solid-state high-temperature fermentation method, and post-fermentation adopts high-salt dilute state low-temperature fermentation method, and post-fermentation is added with soy sauce for aroma enhancement. The amount of yeast added is controlled as follows: 6 x 10 in ml moromi 6 yeast cell count.

[0210] The ingredients are defatted soybeans and wheat.

[0211] The fermentation control process parameters are:

[0212] Pre-fermentation temperature: 44±1°C, post-fermentation temperature: 29±1°C;

[0213] Pre-fermentation water bath: 47±1°C, post-fermentation water bath: 34±1°C;

[0214] Days of pre-fermentation: 19 days, days of post-fermentation: 9 days.

[0215] Among them, the compound immobilized yeast composed of Saccharomyces rouxii, Torulopsis gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com