Fertilizer coated with resin, and its prodn. method

A technology of resin coating and fertilizer, applied in the direction of fertilizer form, fertilizer mixture, fertilization device, etc., can solve the problem of non-recycling and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

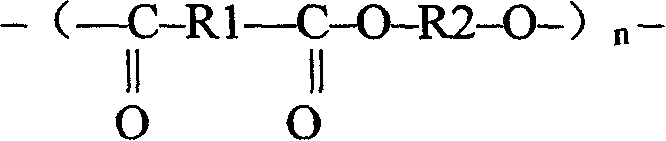

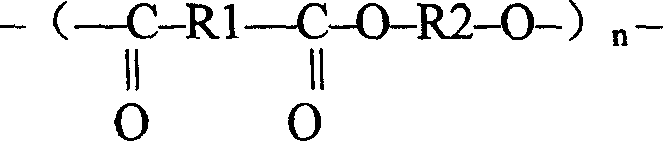

[0024] In this example, the JFB-100 boiling spray coating tower of Jiangsu Keyu Drying Equipment Co., Ltd. is used to dissolve aliphatic polyester and polylactic acid polymer in dichloromethane and ethanol with a mixing ratio of 1:1. In the mixed solvent, powdery fillers are added at the same time to prepare the coating solution. When the proportion of the powdery filler increases, the dissolution rate of the fertilizer components increases, the degradation time of the coating will also be shortened, and the mechanical strength of the coated fertilizer will decrease. , so the addition ratio of powdery filler cannot exceed 60%, its particle size is controlled at less than or equal to 1 / 4 of the film thickness, and it is uniformly dispersed in the coating liquid. Measure 3 kilograms of coating solution, wherein the content of degradable resin film material is 12%; weigh 5 kilograms of granular fertilizers with a particle size of 2 to 4 mm, and the granular fertilizers can be urea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com