Nacrous slurry and its prepn. technique

A pearlescent paste and pearlescent technology, applied in the coating and other directions, can solve the problem of low affinity, and achieve the effect of short production time, preventing secondary bonding and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

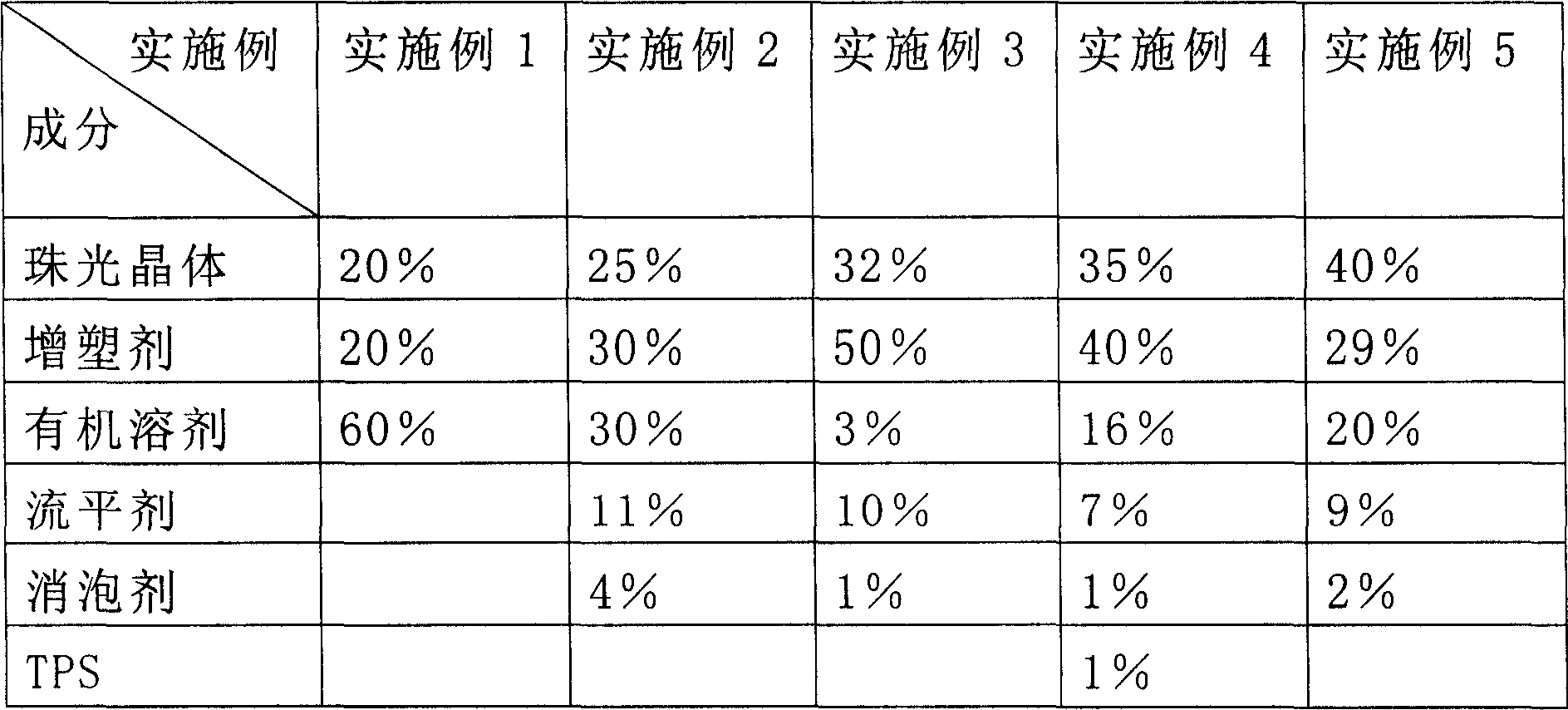

Examples

Embodiment 1

[0046] The preparation process of embodiment 1

[0047] a. Phase inversion treatment: Put the pearlite crystals into pure water with conductivity ≤0.5us / cm to form an aqueous suspension of crystals, and mix dodecylbenzenesulfonic acid with a ratio of 1:1:1 by mechanical stirring Sodium, sodium dodecyl diphenyl ether disulfonate, castor oil sodium sulfate emulsifier and the aqueous suspension of pearlite crystals are mixed and put into a settling tank for sedimentation, and the stirring is stopped when the aqueous suspension of pearlite crystals is exhausted After settling for 1 hour, adopt spraying machinery to spray dichloromethane on the mixed liquid surface, and carry out phase inversion treatment;

[0048] b. Distillation: Put the crystallization after phase inversion treatment-extraction solvent mixture into the still, add the plasticizer as in Table 1, heat the still under stirring and vacuum conditions, turn on the vacuum pump, and adjust the vacuum degree to - 0.01Mpa...

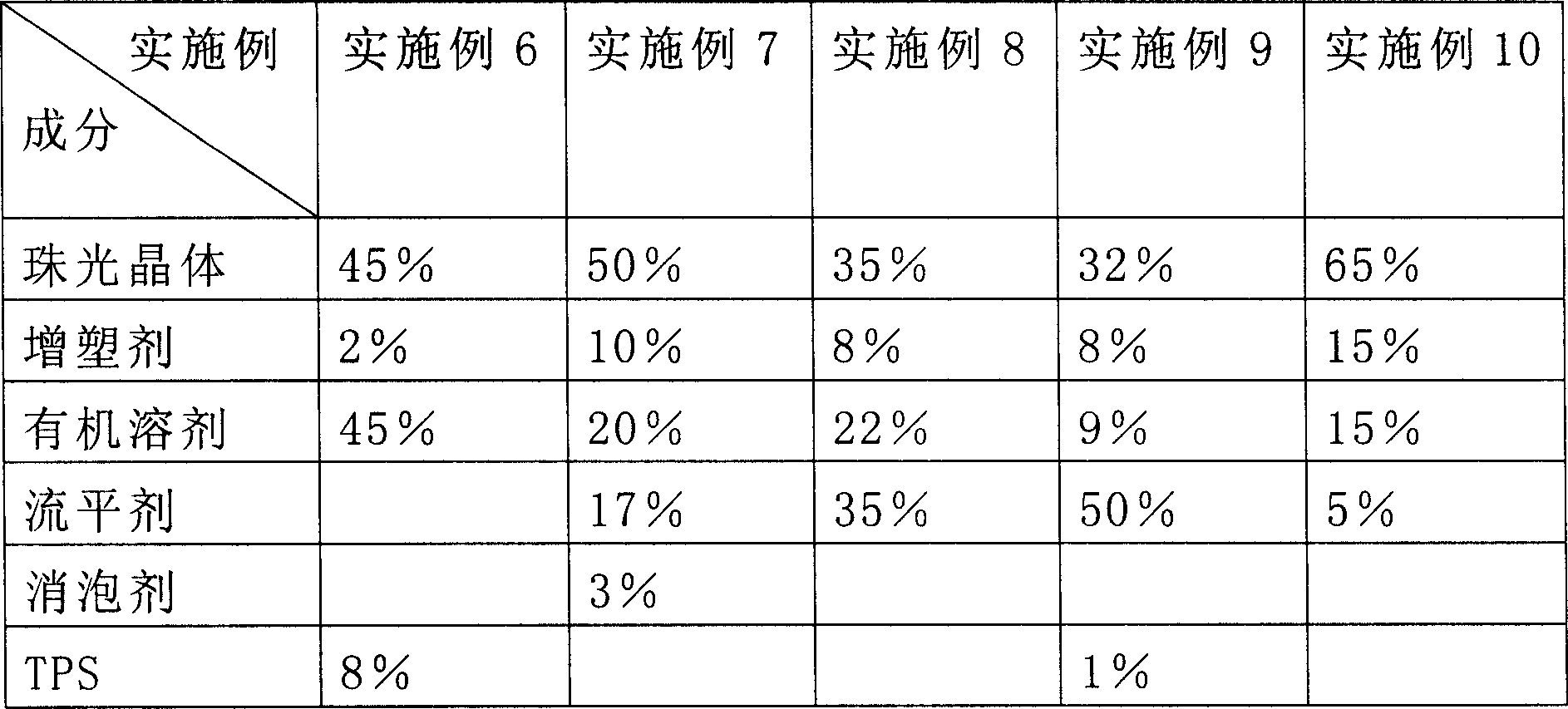

Embodiment 6

[0059] The preparation process of embodiment 6

[0060] a. Phase inversion treatment: put the pearlite crystal into pure water with conductivity ≤0.5us / cm to form an aqueous suspension of crystals, and use mechanical stirring to mix the emulsifier castor oil sodium sulfate and the aqueous suspension of pearlite crystals. Mix and put into the settling tank to settle, and stop stirring when the aqueous suspension of pearlite crystals is finished; after settling for 2 hours, use a spraying machine to spray chloroform on the mixed liquid surface, and perform phase inversion treatment;

[0061] b. Distillation: Put the crystallization after phase inversion treatment-extraction solvent mixture into the still, add the plasticizer as in Table 2, heat the still under stirring and vacuum conditions, turn on the vacuum pump, and adjust the vacuum degree to - 0.05Mpa, distillation time is 3.5 hours;

[0062] c. Blending: add the above-mentioned distilled pearlescent crystals to other ing...

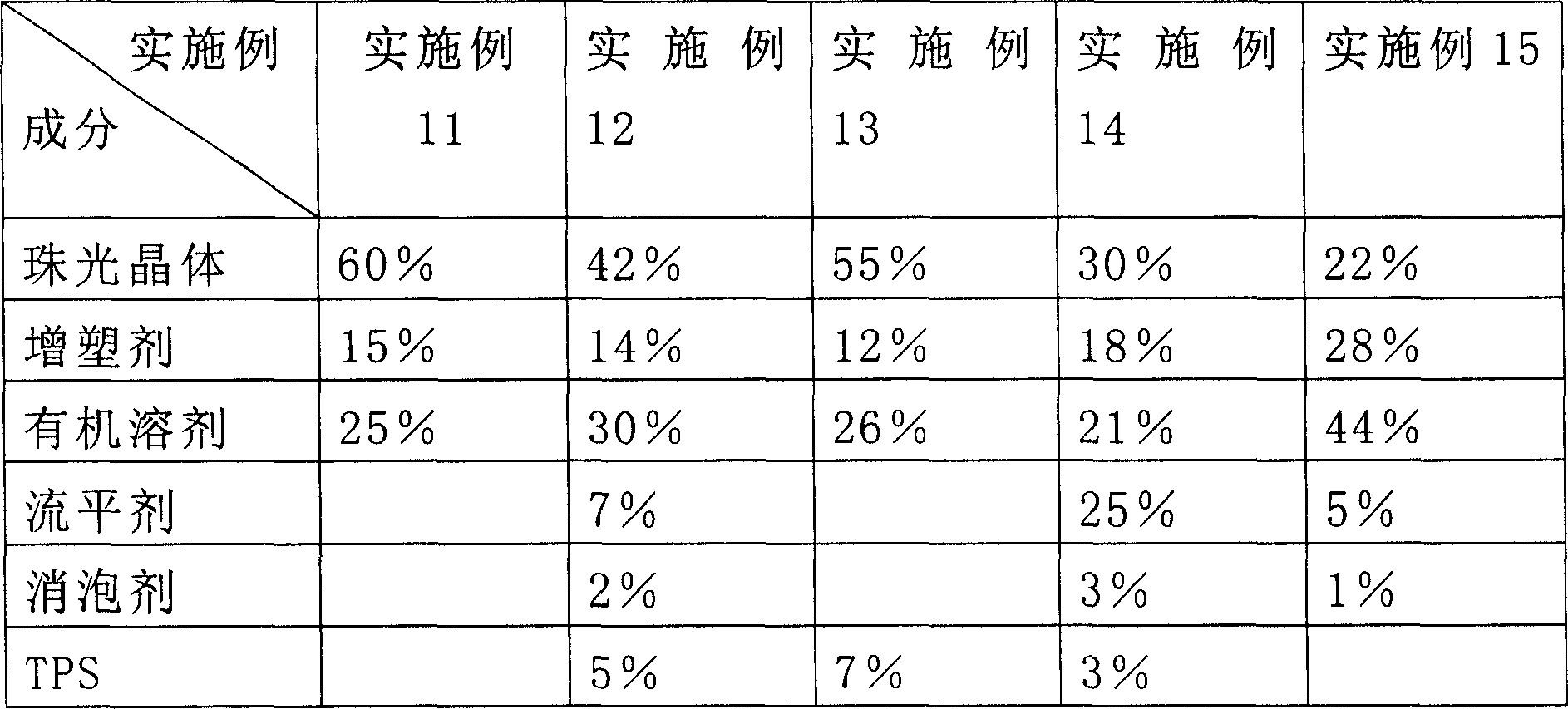

Embodiment 11

[0072] The preparation process of embodiment 11

[0073] a. Phase inversion treatment: put the pearlite crystal into pure water with conductivity ≤0.5us / cm to form an aqueous suspension of crystals, and use mechanical stirring to mix the emulsifier castor oil sodium sulfate and the aqueous suspension of pearlite crystals. Mix and put into the settling tank to settle, stop stirring when the aqueous suspension of pearlite crystals is finished; after settling for 3 hours, use a spraying machine to spray dibutyl butyl phosphonate on the mixed liquid surface, and perform phase inversion deal with;

[0074] b. Distillation: Put the crystallization after the phase inversion treatment-extraction solvent mixture into the distillation still, add the plasticizer as in Table 3, heat the still under stirring and vacuum conditions, turn on the vacuum pump, and adjust the vacuum degree to - 0.092Mpa, the distillation time is 2 hours;

[0075] c. Blending: add the above-mentioned distilled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com