Tester and method for residual stress of seniconductor material

A technology of residual stress and testing equipment, which is applied in the field of semiconductors, can solve the problems of destroying the integrity of the material lattice, large measurement errors, and complicated and lengthy testing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

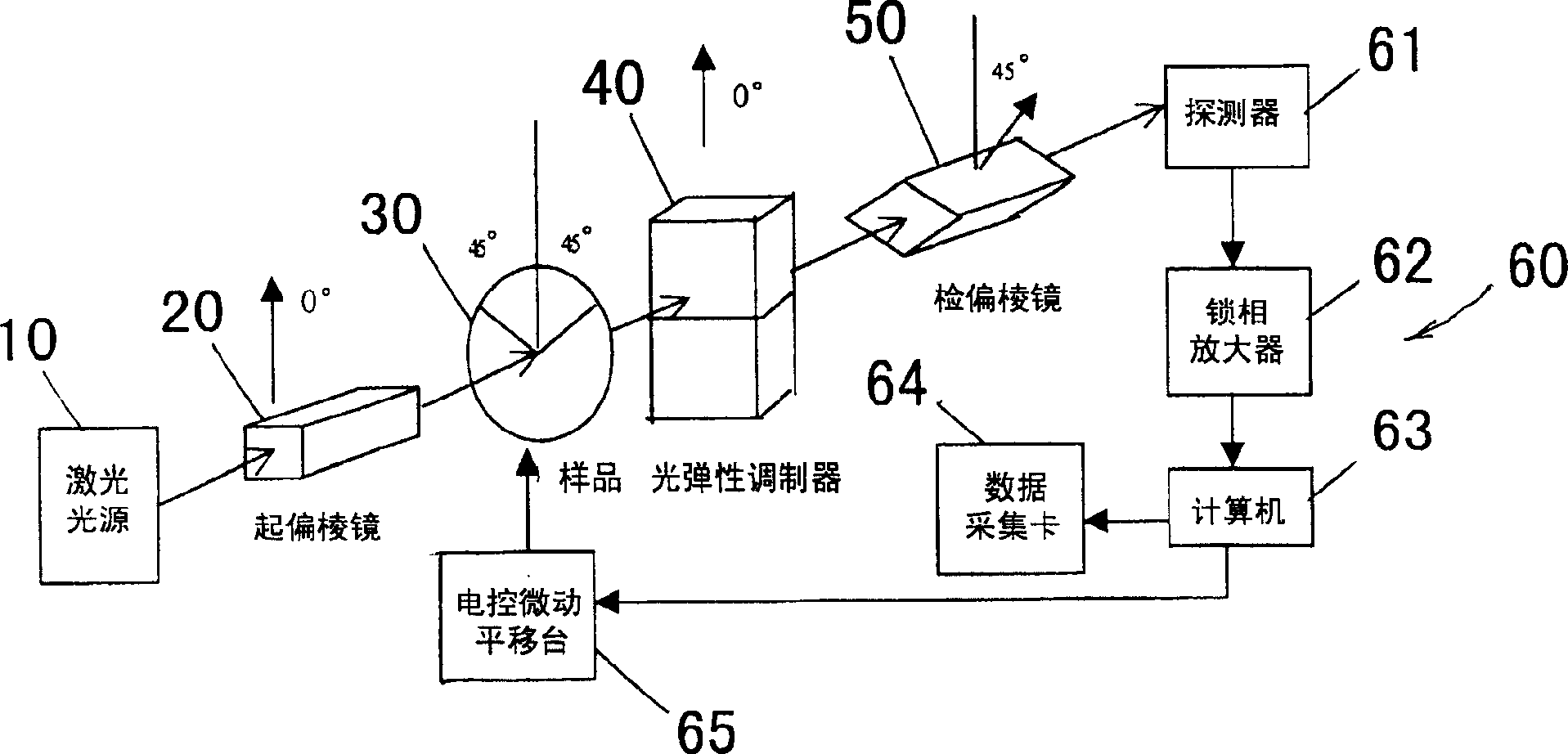

[0059] 1. Use laser diode pumped YAG solid-state laser light source with a wavelength of 1064nm.

[0060] 2. Put the 6-inch gallium arsenide wafer on the (001) plane into the testing system.

[0061] 3. Adjust the optical path and select the test point so that the polarization plane of the incident laser light is parallel to the surface of the test sample, and forms an included angle of 45 degrees with the directions [110] and [110] on the surface of the gallium arsenide wafer.

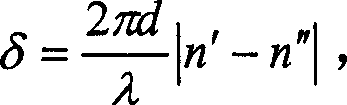

[0062] 4. Measure the strength-transmittance ratio difference ΔT / T in the [110] and [110] directions on the surface of the gallium arsenide wafer, and use the formula (1) described later to obtain the stress of the test point.

[0063] 5. Use computer programming to control the sample to automatically move to the next test point, repeat step 4, and measure the stress of this point.

[0064] 6. Step 5 is repeated until the entire GaAs wafer is tested to obtain the stress distribution of the entire GaA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com