Preparation of visible light -initiated nano superlong-persistence luminescent materials

A long afterglow luminescence and visible light technology, applied in the field of materials, can solve the problems of industrial production of ultra-long afterglow nano-rare earth luminescent materials excited by visible light, lack of powder, and large particle size of powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Ultra-long afterglow luminescent material (sample 1)

[0059] Take strontium nitrate (0.025mol), aluminum nitrate (0.0925mol), europium nitrate (0.000385mol), dysprosium nitrate (0.00077mol), and dissolve them in 200 ml of 6mol / L HNO 3 , stir to make it fully mixed to form a mixture solution.

[0060] Ammonium carbonate (0.2 mol) precipitant was added and allowed to stand for 30 minutes, resulting in precipitation.

[0061] The resulting precipitate was placed in a reducing atmosphere (such as 3% H 2 -97%N 2 ) to 800° C., and then kept at this temperature for 3.5 hours to obtain the ultra-long afterglow luminescent material (sample 1) of the present invention.

Embodiment 2-4

[0063] Ultra-long afterglow luminescent material (sample 2-4)

[0064] According to the similar method described in Example 1, the difference lies in the use of each combination content and preparation conditions shown in Table 1, as a result, the ultra-long afterglow luminescent material of the present invention (sample 2-4) was obtained.

[0065] Example 1

Embodiment 5

[0067] performance measurement

[0068] In this example, the dimensions and properties of samples 1-4 prepared in Example 1 were tested.

[0069] (a) Average particle size and composition

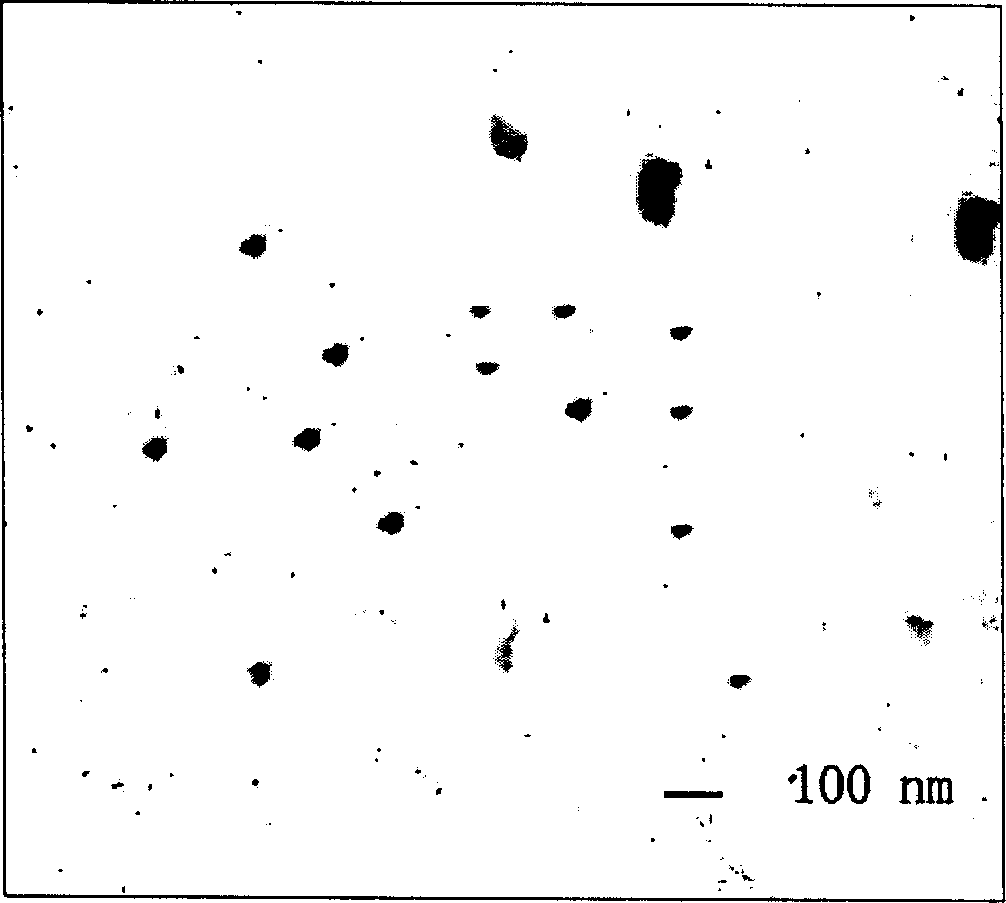

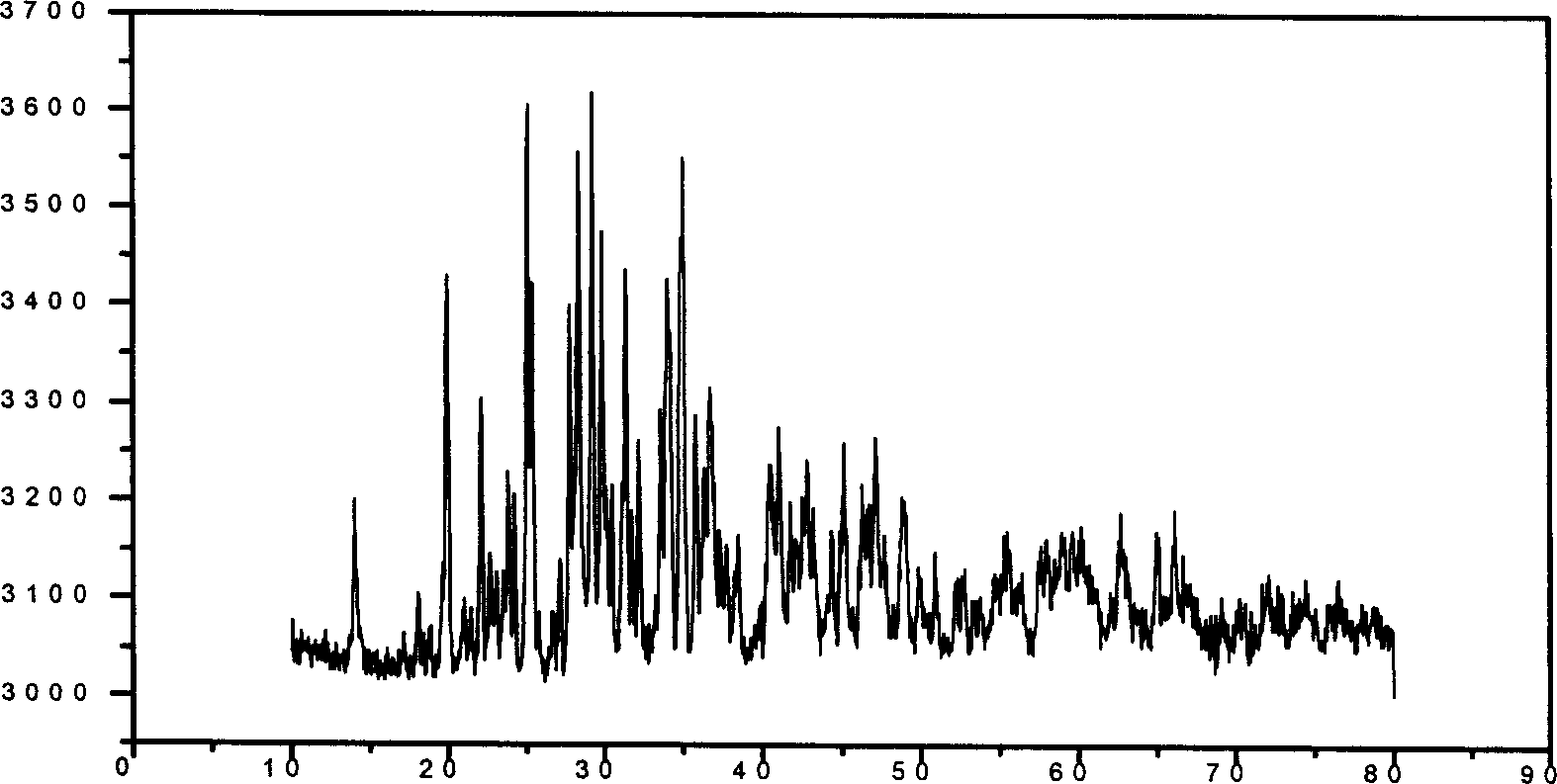

[0070] The average particle size was determined by TEM electron microscope. Determination of its composition by XRD powder diffraction method

[0071] TEM results as figure 1 shown. The results showed that the particle diameters of the samples all reached the nanometer level, and the average particle diameter was 30-60nm. (Note: figure 1 Shown is a particle diameter photograph of sample 1).

[0072] XRD powder diffraction shows as figure 2 shown. The results show that its composition is Sr 4 al 14 o 25 :Eu 2+ , Dy 3+ , wherein Sr: 2Al: Eu: Dy is calculated from the amount of each raw material in Table 1.

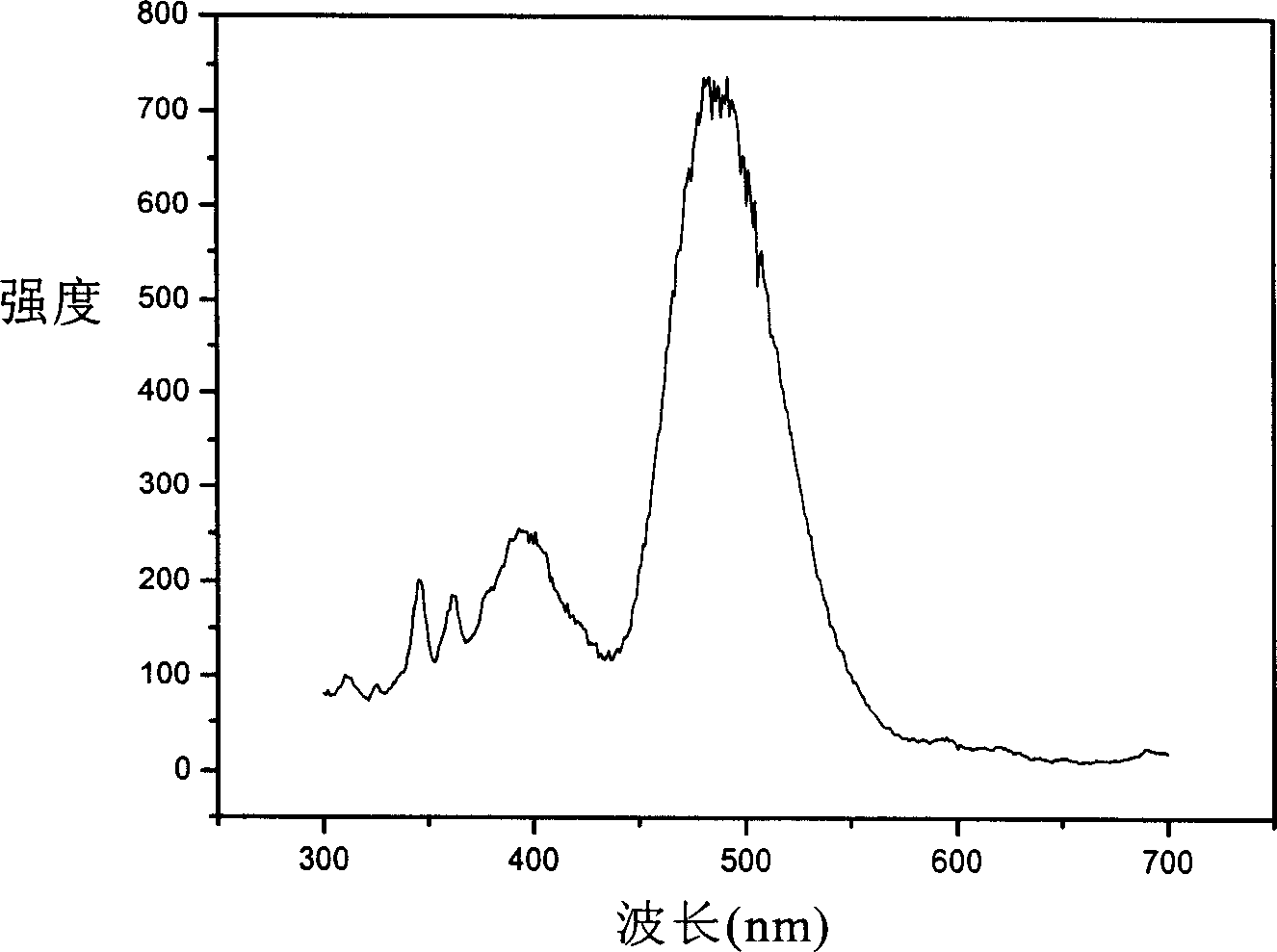

[0073] (b) Afterglow performance

[0074] Measure the luminous performance of sample 1-4 with routine Cary Eclipse method, the afterglow intensity (mcd / m2) of each sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com