Method for culturing chlorella with high-density and high-quality

A technology of chlorella and common chlorella, applied in the biological field, can solve the problems of easy contamination of miscellaneous bacteria, difficulty in amplification, inconvenient cleaning, etc., and achieve the effect of high-density and high-quality cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

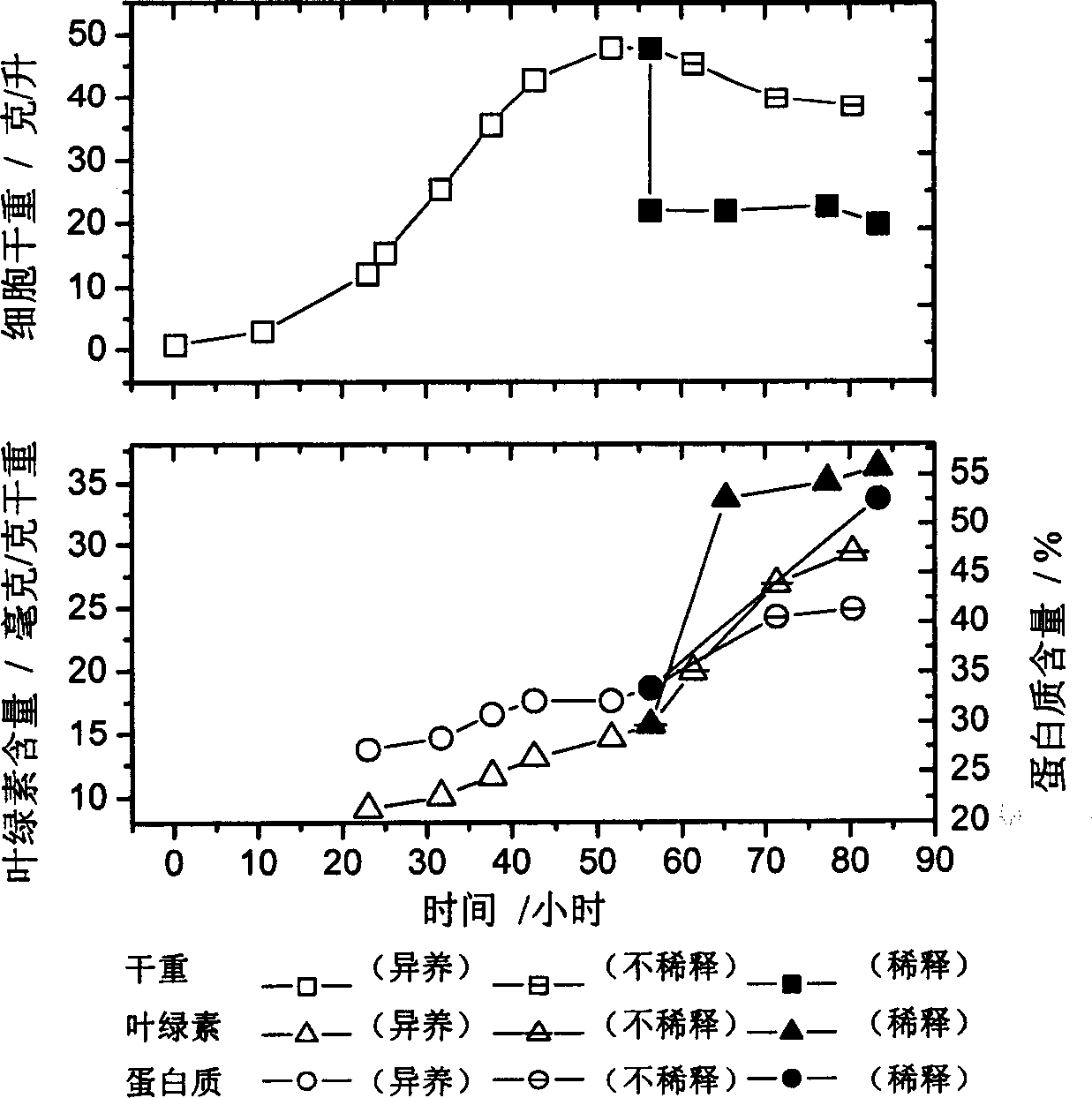

Embodiment 1

[0063] Add the following heterotrophic culture medium into a 5L bioreactor, add tap water to 3.4L and then sterilize, then insert Chlorella vulgaris into 6% of the working volume when the temperature drops to 30°C, and start heterotrophic culture . Heterotrophic culture conditions: the temperature is 30°C, the rotation speed is gradually adjusted from 200r / min at the time of inoculation to 400r / min at the end of the culture, the air flow rate is 1vvm, the pH is less than 8.5, and the dissolved oxygen is controlled above 15%. 30h after inoculation, feed solution (20g / L glucose and 3.33g / LKNO 3 mixed solution), and then added once every 5 to 8 hours, for a total of 4 times. After culturing for 56.34h, the dry cell weight (□) reached 47.91g / L, and the algal protein (□) and chlorophyll (□) contents were 33.42% and 15.65mg / gDcw respectively (see figure 1 ), the heterotrophic culture period ended.

[0064] KNO 3 : 9.25 Glucose: 30

[0065] K H 2 PO 4 : 0.7 Na 2 HPO 4 12H2 O...

Embodiment 2

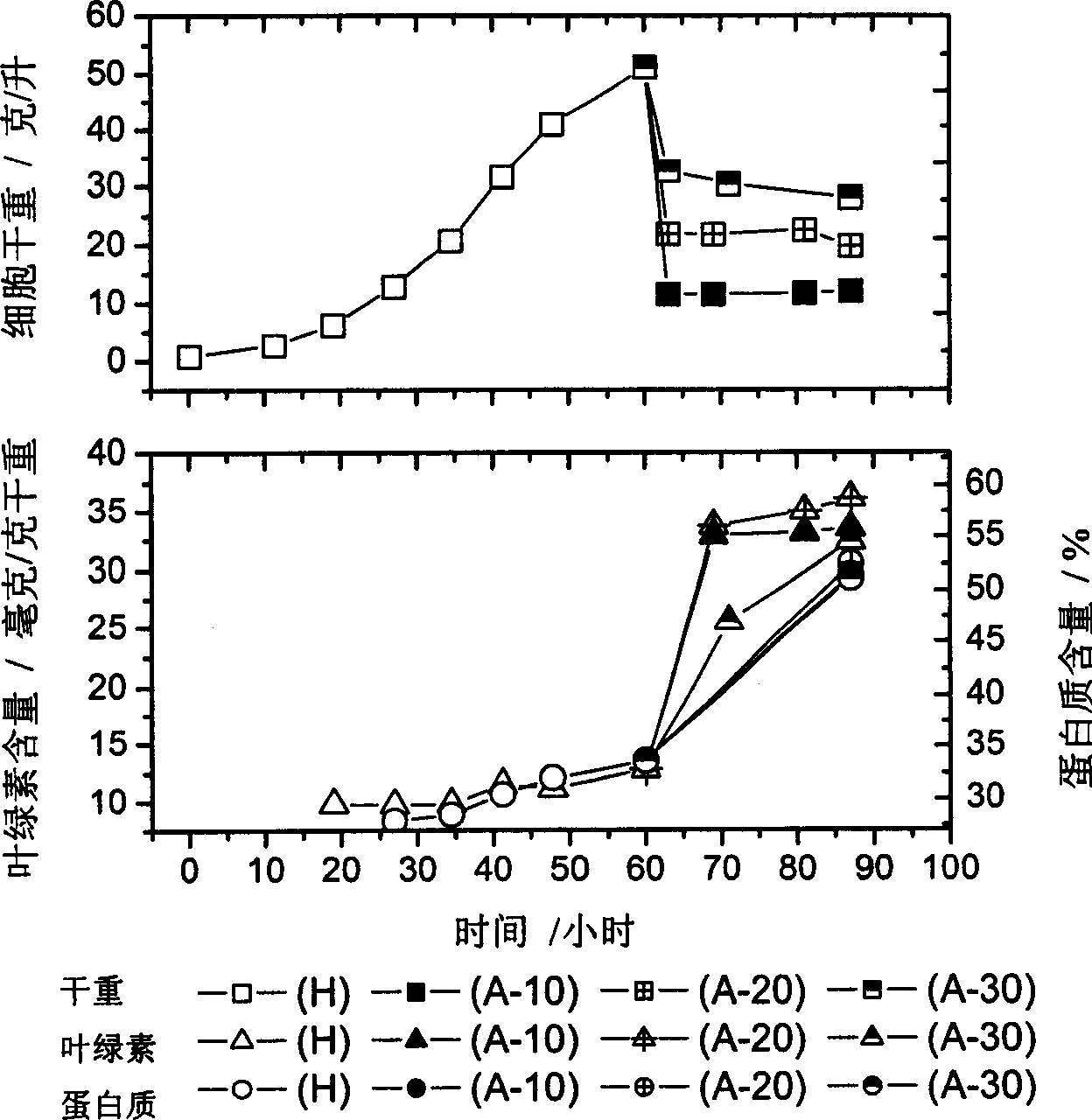

[0083] Add the culture medium adopted by heterotroph in Example 1 into a 5L bioreactor, and adopt the heterotrophic culture conditions and culture techniques used in Example 1 to cultivate Chlorella vulgaris. After culturing for 60.08 hours, the dry cell weight (□) reached 51.15g / L, and the contents of algae protein (○) and chlorophyll (□) were 33.65% and 12.80mg / gDcw respectively (see figure 2 ), the heterotrophic culture period ended.

[0084] Use the following dilutions of the medium used, where KNO 3 The contents are 2.60g / L, 4.95g / L and 7.36g / L respectively, and the high-density algal liquid obtained from heterotrophic culture is diluted to 11.45g / L (A-10) and 21.89g / L (A-20) respectively and 32.56g / L (A-30) were transferred to a 1L flat photobioreactor for photoautotrophic culture. The photoautotrophic culture conditions were the same as in Example 1. Continue to cultivate until 87.08h, when the initial dry cell weight is 11.45g / L after transferring to photoautotroph...

Embodiment 3

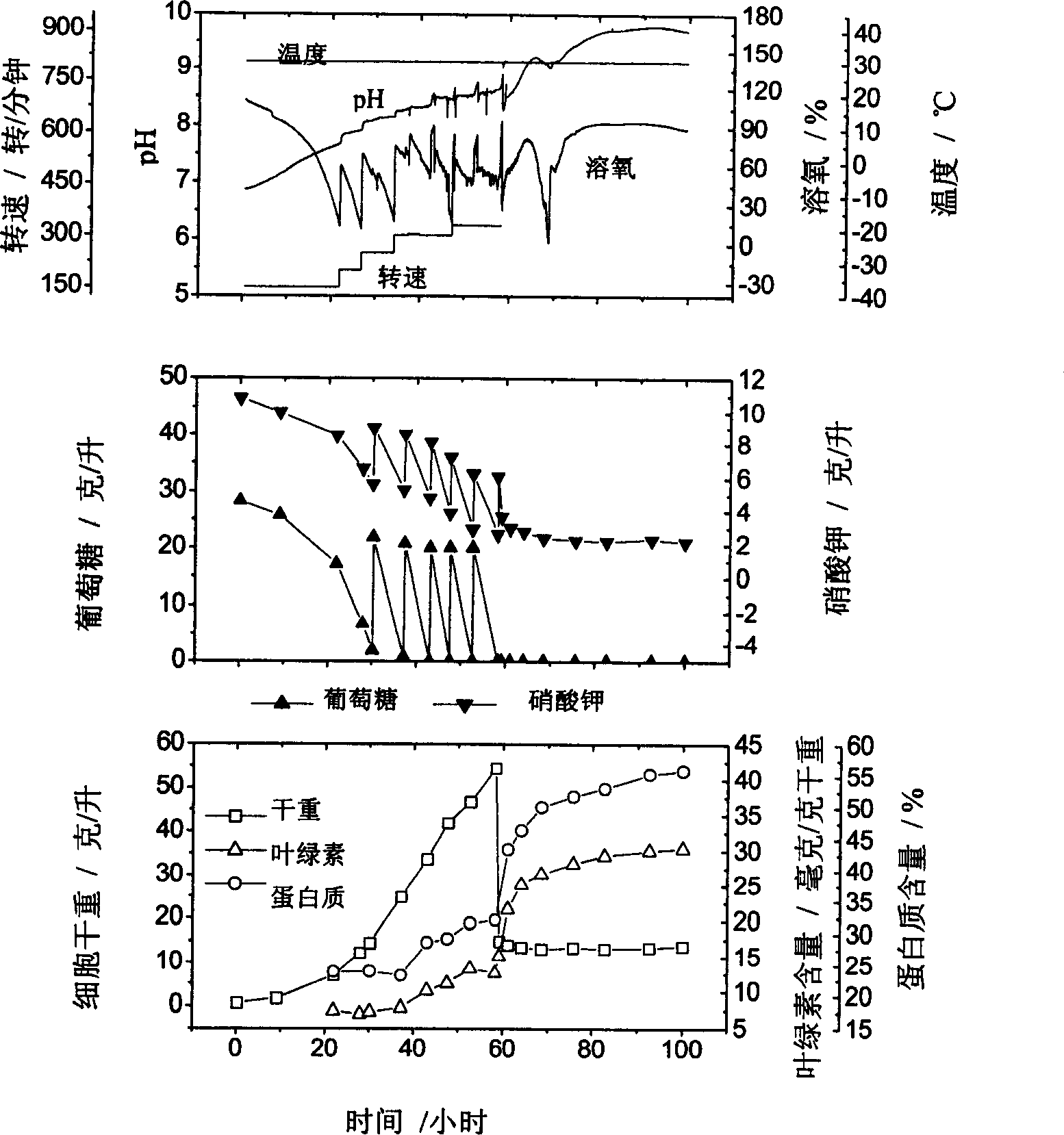

[0094] Add the medium used in heterotrophy in Example 1 to a 50L bioreactor, add tap water to 34L and then sterilize it, then insert Chlorella vulgaris into 6% of the working volume when the temperature drops to 30°C, and start heterotrophy to cultivate. The heterotrophic culture conditions and culture techniques used in Example 1 were used to cultivate Chlorella vulgaris, wherein the feeding times were increased to 5 times. Cultivate to 58.20h dry cell weight reaches 54.52g / L, algal body protein and chlorophyll content are respectively 32.01% and 12.70mg / gDcw (see image 3 ), the heterotrophic culture period ended.

[0095] The high-density algae cell that 50L bioreactor heterotrophic culture obtains adopts the substratum (wherein KNO 3 Content is 2.60g / L) is diluted to 14.88g / L, then transfers to 30L plate type photobioreactor and carries out photoautotrophic culture. Photoautotrophic culture conditions: the temperature is 30°C, the liquid volume is 24L, the air flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com