Chitose base self-assembly nano microcapsule preparation method and its drug release regulation method

A technology of nano-microcapsules and chitosan, applied in the N field, can solve the problem that microcapsules cannot reach nanometer size, and achieve the effects of improving drug release rate, simple operation and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

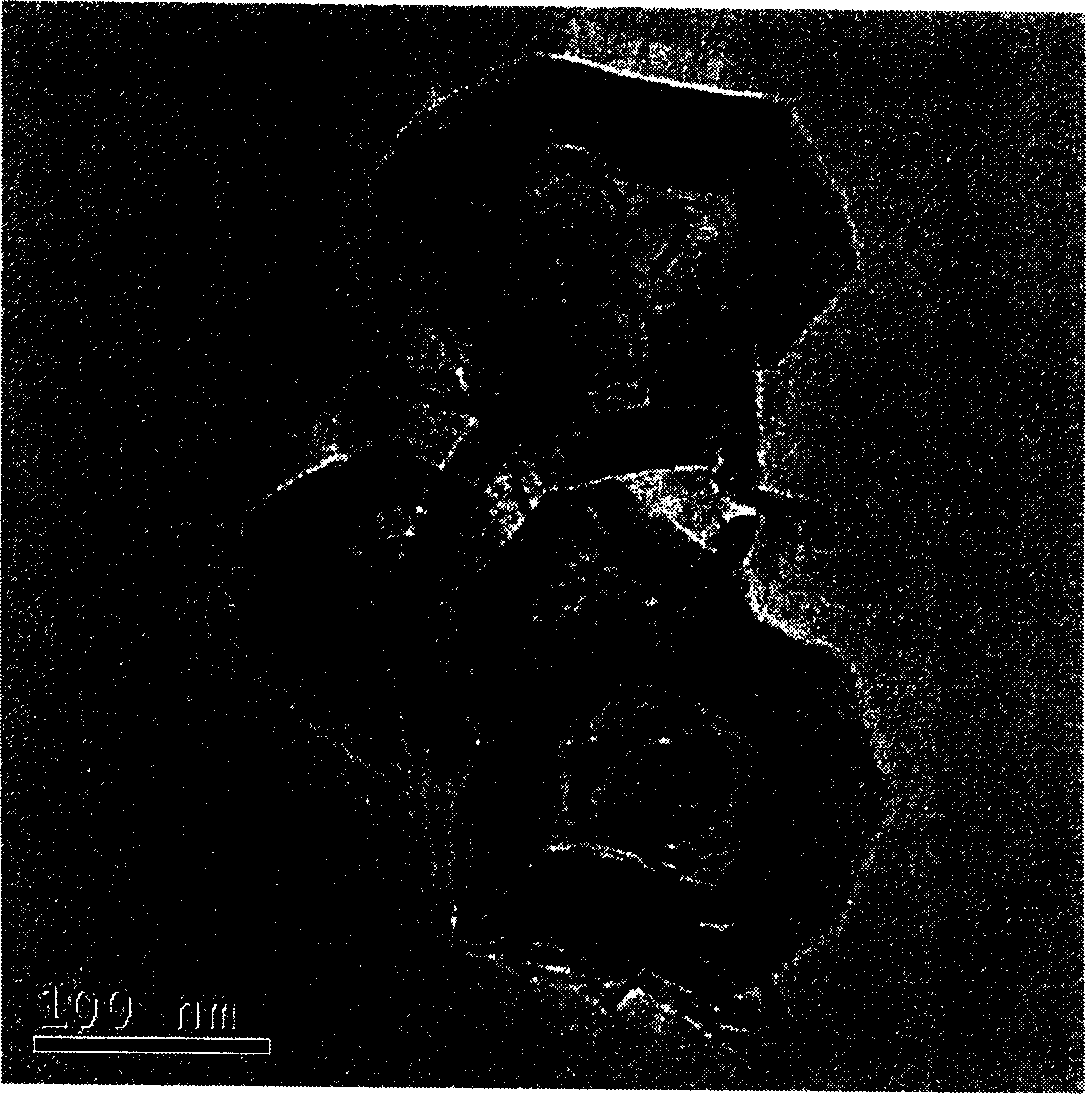

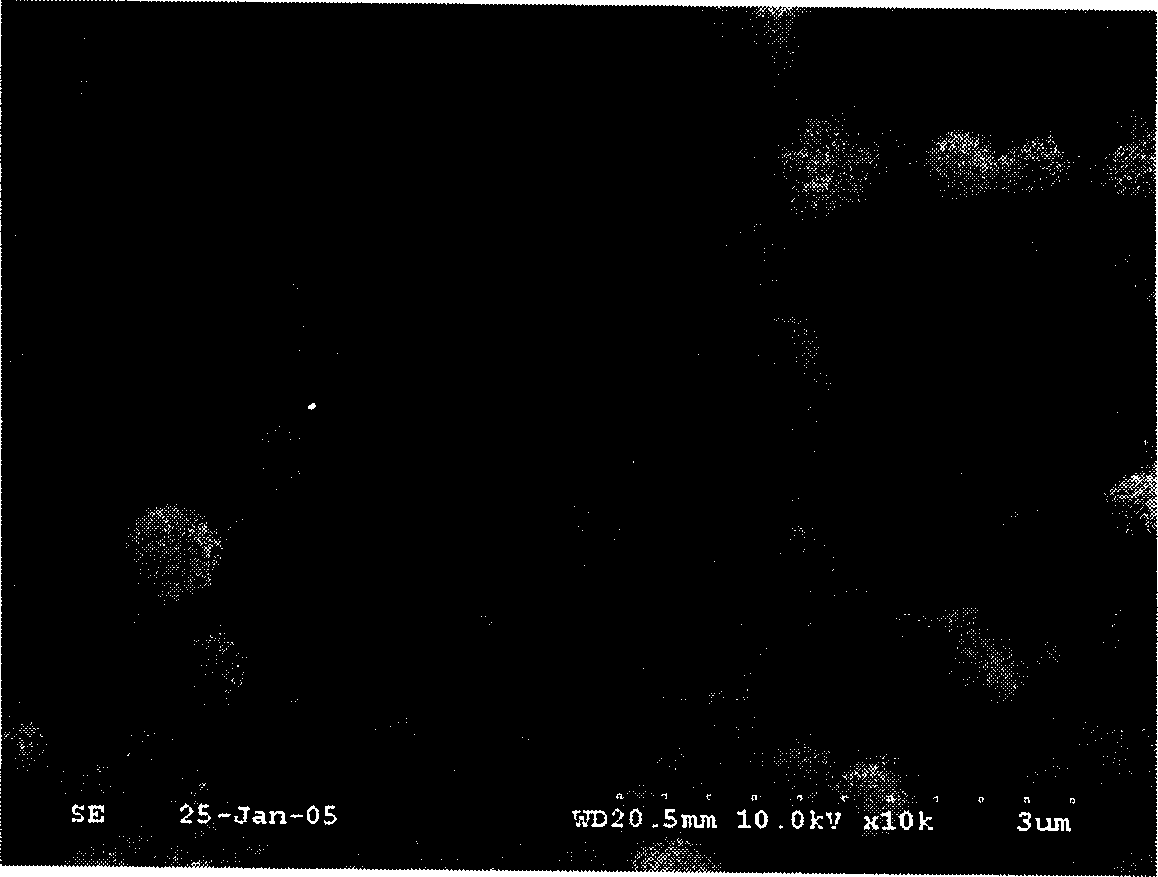

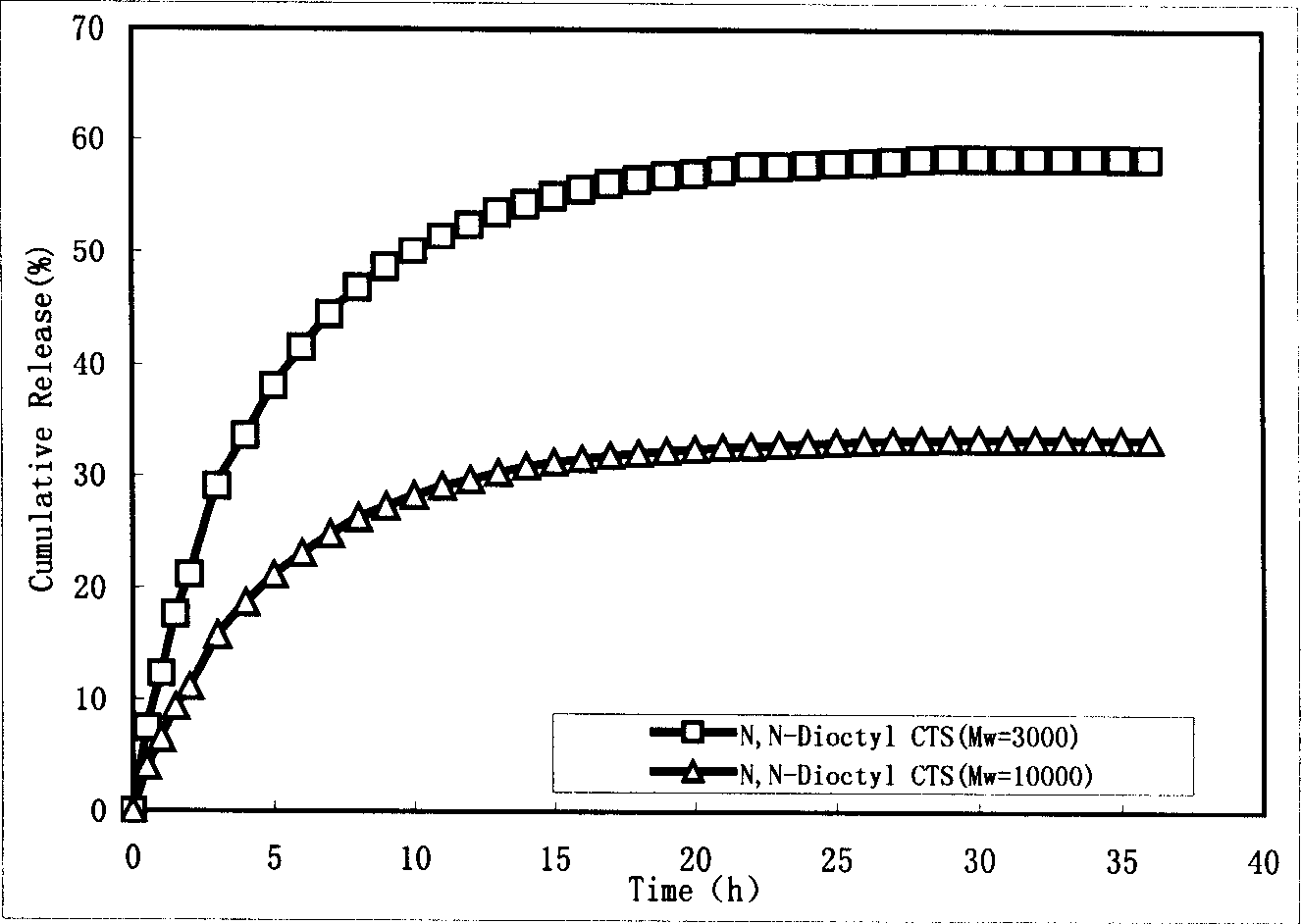

[0029] In order to better understand and implement, the following combination figure 1 , figure 2 , image 3 , Figure 4 The preparation method of the chitosan-based self-assembled nano-microcapsule and the drug release regulation method of the present invention are described in detail with the examples.

[0030] The preparation method of N, N-bis-octyl chitosan self-assembled nano-medicine microcapsules is realized by the following scheme: 0.1G N, N-bis-octyl chitosan is dissolved in 24mL chloroform, Add 8 mL of V at a concentration of 4.0 mg / mL B12 aqueous solution. Bath ultrasonication for 15-30 minutes to form a W / O emulsion. The resulting emulsion was evaporated under reduced pressure to remove chloroform to a semi-solid gum. It was placed in a vacuum desiccator at room temperature for 12 hours to further remove remaining chloroform. Then ultrasonicate in a powerful sonicator for 3-12 minutes to obtain drug-embedded N, N-bis-octylated chitosan-based self-assembled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com