Method and apparatus for processing composite abrasive material by overlapped vibration

A composite abrasive and processing method technology, which is applied in the field of grinding processing, can solve the problems of easy occurrence of abnormal cracks, increased internal stress of the workpiece, and high processing costs, and achieves improved ultrasonic processing efficiency, improved tool wear resistance, and low processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

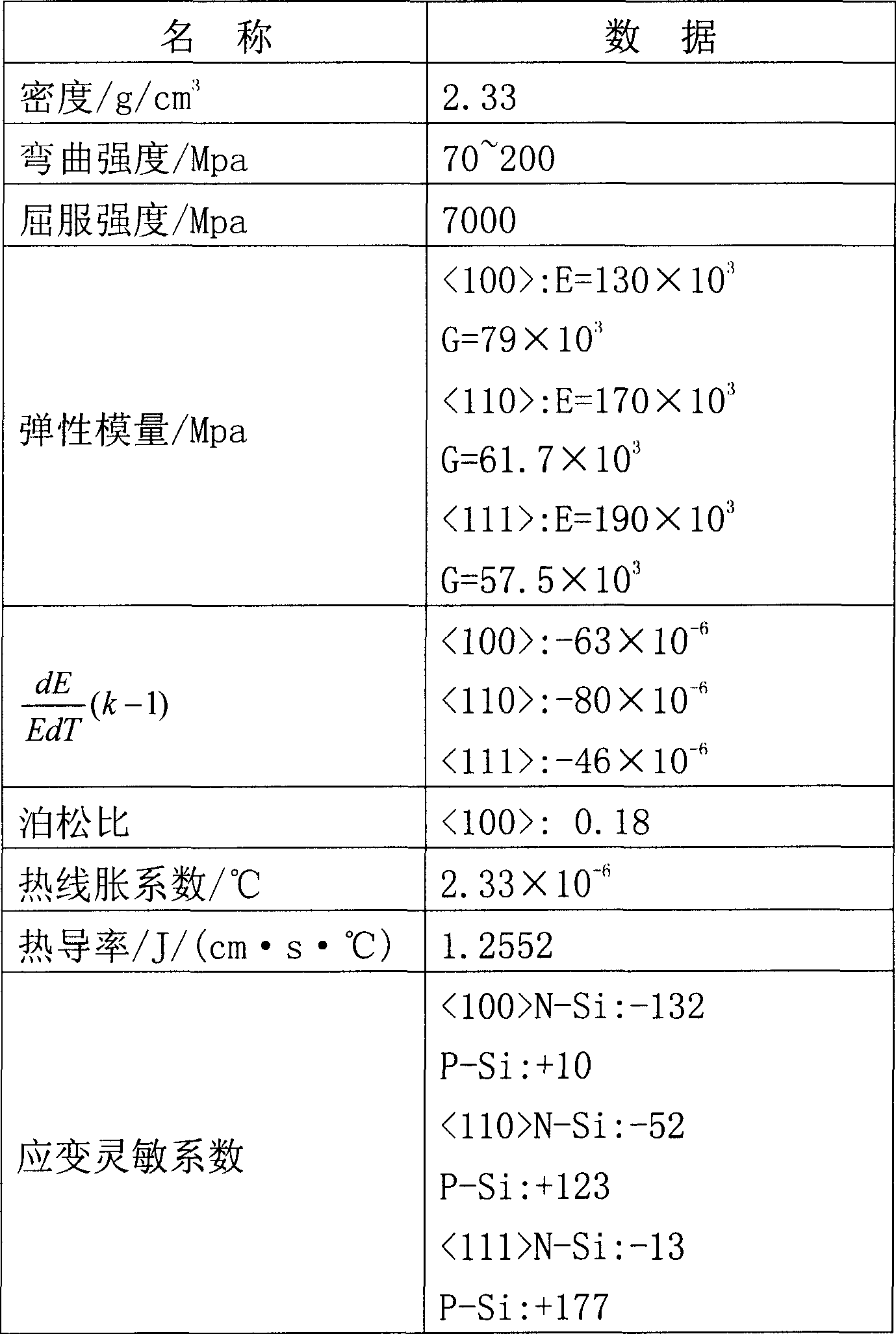

[0047](1) When the overlapping vibration composite abrasive processing method is used for processing, the hard and brittle materials to be processed are not easily broken. The vibration parameters are:

[0048] Low frequency vibration frequency F=20~200Hz, amplitude A=200~300μm;

[0049] Ultrasonic vibration frequency f = 15000-30000 Hz, amplitude a = 15-50 μm.

[0050] (2) The tool wear ratio is 200:1.

[0051] (3) Free abrasive particle size: 180#~280#; diamond abrasive particle size: 120#~180#.

[0052] (4) Machining accuracy: 0.001~0.003mm.

[0053] (5) Surface roughness Ra0.2μm.

[0054] (6) Processing efficiency: 0.5~0.8mm / min.

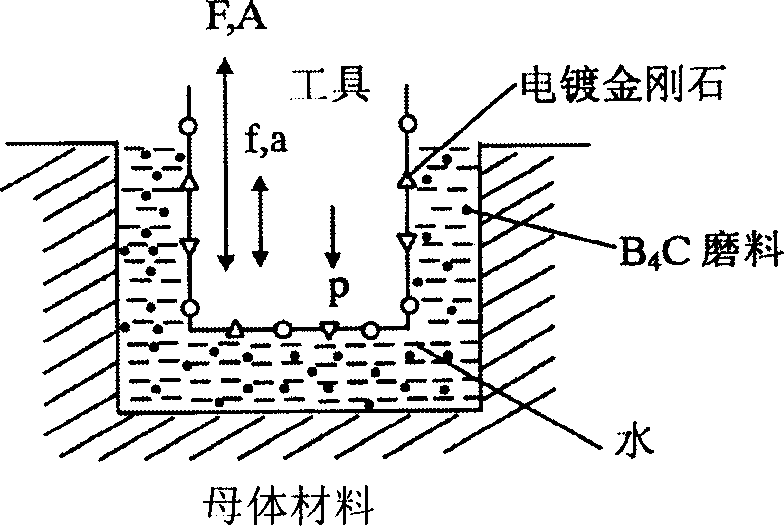

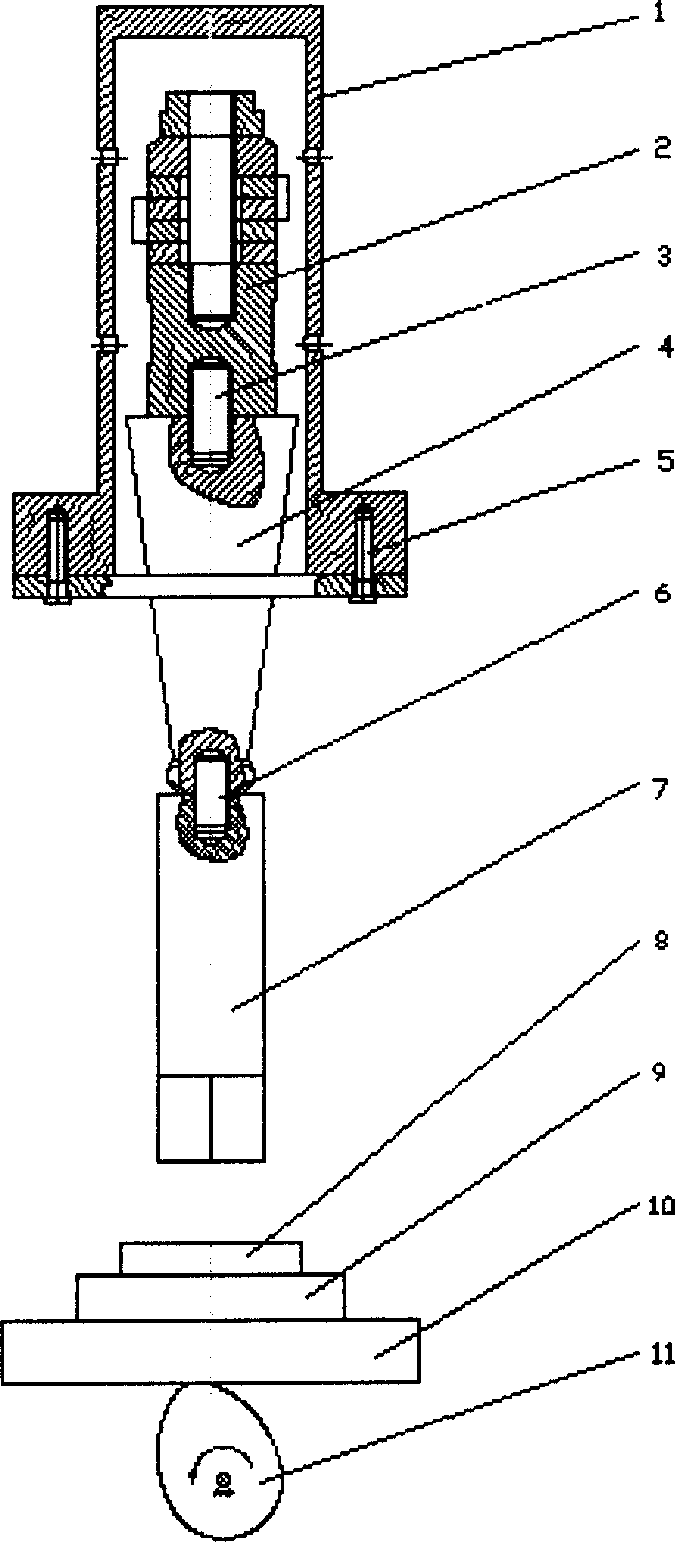

[0055] In the overlapping vibration composite abrasive machining process, using water as the medium, the B 4 C abrasive is evenly dispersed in water, and low-frequency vibration and ultrasonic vibration are simultaneously applied to electroplated diamond tools for efficient and precise machining. The ultrasonic machining acoustic system c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com