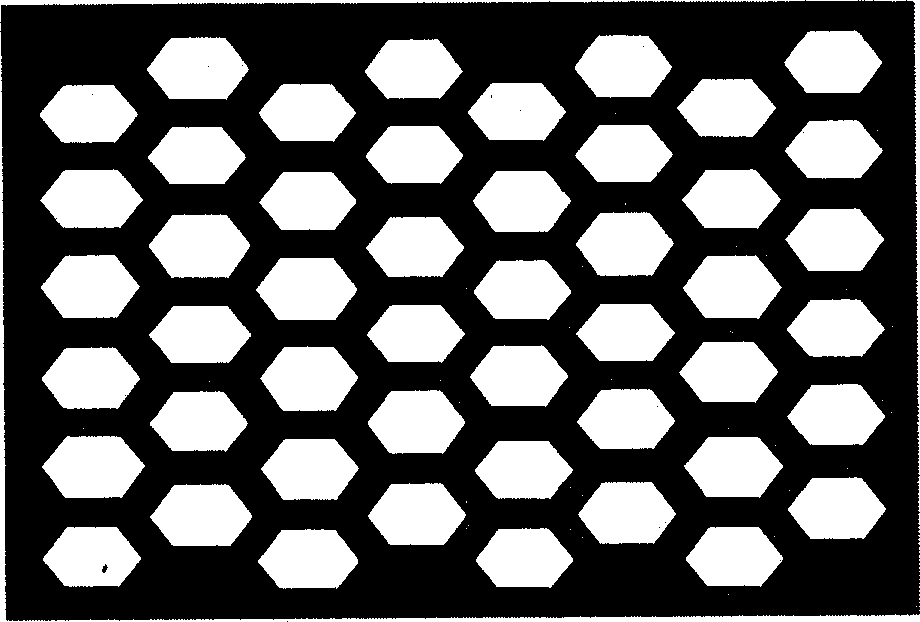

Perforated plant fiber board, its manufacturing method and equipment dedicated therefor

A plant fiber and manufacturing method technology, applied in manufacturing tools, other household appliances, applications, etc., can solve the problems of low internal bonding strength and compressive strength, large gradient of cross-sectional density distribution, low static bending strength, etc. Light, simple equipment, good quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: one-time molding process

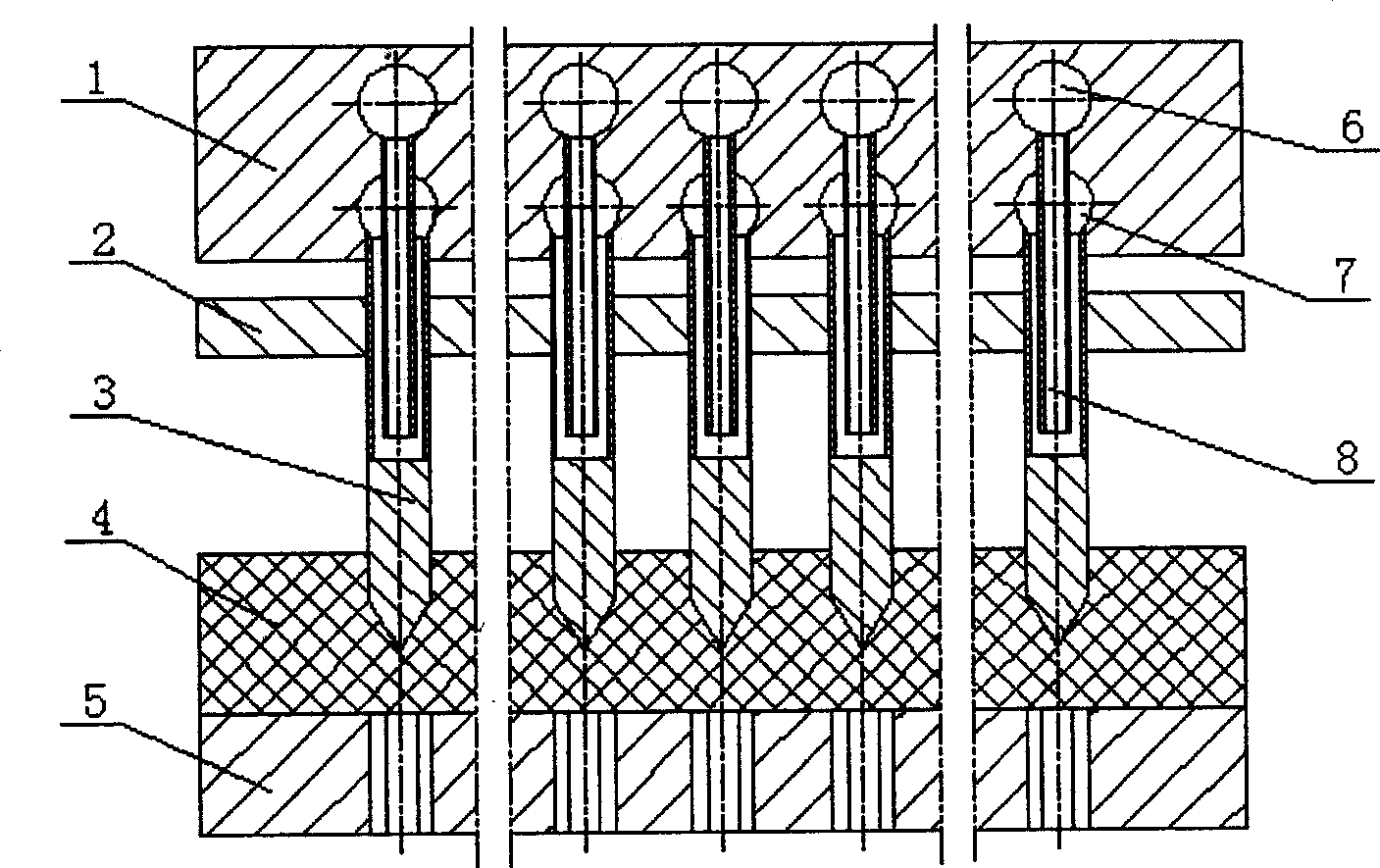

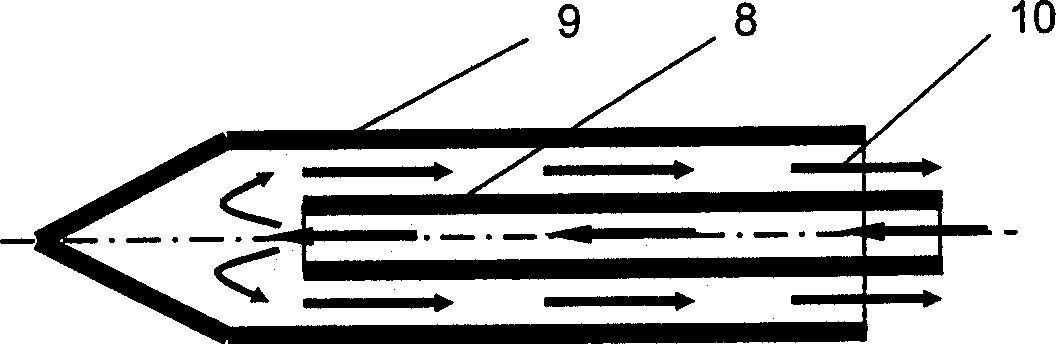

[0034] In conjunction with the accompanying drawings: the hot press of this embodiment is composed of several parts such as an upper platen 1, a stripper plate 2, a tip punch 3, and a lower platen 5. The cross-sectional shape of the punch 3 is various polygons, and the inside of the punch is hollow. The pointed end faces downwards, and the upper end of the punch is provided with an inner sleeve 8 for the hot oil inlet and an outer sleeve 9 for the hot oil outlet; a section of the front end of the punch in this embodiment is made of non-metallic material, so that when the punch is inserted In the slab, when the compression ratio of the slab is relatively small, the slab may not be heated, and only when the slab reaches a certain compression ratio, the slab is heated.

[0035] A series of channels for fixing the punch are drilled on the fixed punch and the upper pressing plate that pressurizes the slab. The inner casing is installe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com