Combined holophote laser resonant cavity composed of right-angle round platform inboard surface and right-angle taper outboard surface

A technology of laser resonator and inner side, applied in the field of laser resonator, can solve the problems of inability to eliminate the uneven distribution of the center and edge of the gain medium, inability to realize the laser output of a circular hollow spot, and low thermal stability of the right-angle conical prism cavity, etc. Reliable performance, easy modification, and reduced thermal distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

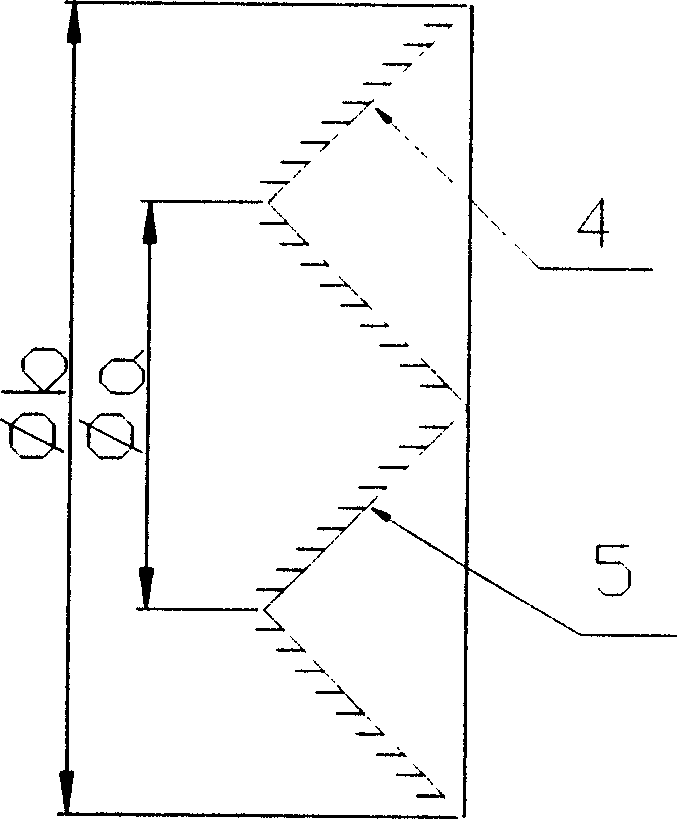

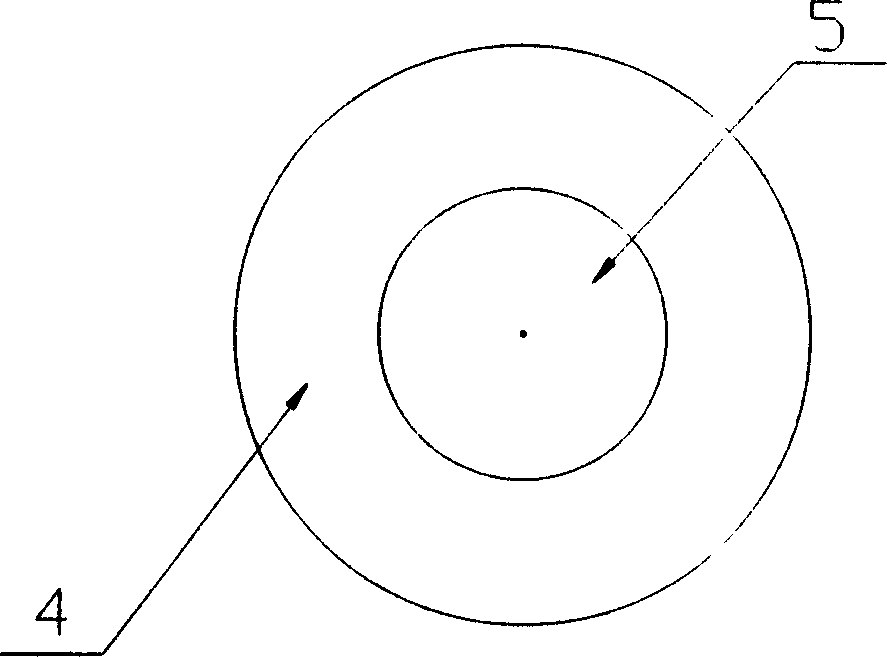

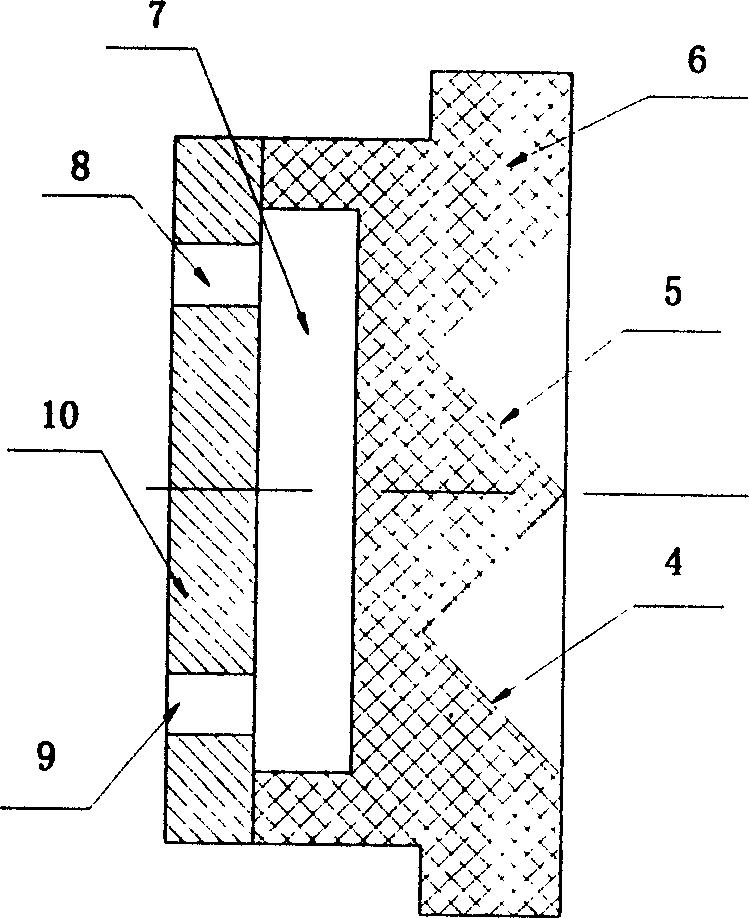

[0044] Depend on Figure 6 ~ Figure 7As shown, the present invention includes a total reflection mirror 1, an output mirror 2 and a laser working medium 3. The total reflection mirror 1 is composed of an inner surface 4 of a right-angled circular frustum and an outer surface 5 of a reverse right-angled cone. The output mirror 2 is an integral plane mirror composed of a circular plane 11 and a concentric ring-shaped plane 12 on the edge. The circular plane 11 is coated with a semi-transparent and semi-reflective film as a laser output port, and the ring-shaped plane 12 is coated with a high-reflection film. , the dimensional relationship between them is Φd=Φb=2Φc, where Φc is the diameter of the circular plane 11 , and Φd is the diameter of the output mirror 2 .

[0045] Embodiment 1 The effective laser output spot area of the laser resonator is 1 / 4 of the bottom surface area of the total reflection mirror 1, which can greatly increase the laser output power density. The r...

Embodiment 2

[0047] Depend on Figure 8 ~ Figure 11 As shown, the present invention includes a total reflection mirror 1, an output mirror 2 and a laser working medium 3. The total reflection mirror 1 is composed of an inner surface 4 of a right-angled circular frustum and an outer surface 5 of a reverse right-angled cone. The output mirror 2 is a split output mirror, which is made up of a circular plane half-mirror 13 and a concentric annular plane full-mirror 14 on the edge, and the circular plane half-mirror 13 and the annular plane full-mirror 14 The axis of rotational symmetry is coaxial, and the dimensional relationship between each other is Φd=Φb=2Φc, Φe>Φc, Φf>Φd, wherein Φc is the diameter of the circular flat half mirror 13, and Φd is the diameter of the output mirror 2, Φe is the installation size of the circular plane half-mirror 13, and Φf is the installation size of the output mirror 2. 15 is an annular cooling water tank of the output mirror 2, and 16 is an annular cover pl...

Embodiment 3

[0050] Depend on Figure 12 to Figure 14 As shown, the present invention includes a total reflection mirror 1, an output mirror 2 and a laser working medium 3. The total reflection mirror 1 is composed of an inner surface 4 of a right-angled circular frustum and an outer surface 5 of a reverse right-angled cone. The output mirror 2 is a split output mirror, which is made up of the concentric ring-shaped total reflection mirror 17 of the circular plane half-mirror 13 and the edge, and the concentric ring-shaped total reflection mirror 17 is composed of the inner surface 18 and the The outer surface 19 of the opposite second right-angled circular platform is formed, and the rotational symmetry axis of two right-angled circular platforms is coaxial, and the inner surface 18 and the outer surface 19 are high reflective surfaces, and the circular plane half-transparent half-mirror 13 and the concentric The ring-shaped total reflection mirror 17 has the same axis of rotational symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com