Exhaust gas catalytic converter

一种催化净化、尾气的技术,应用在排气装置、催化剂活化/制备、非均相催化剂化学元素等方向,能够解决发动机室变窄等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

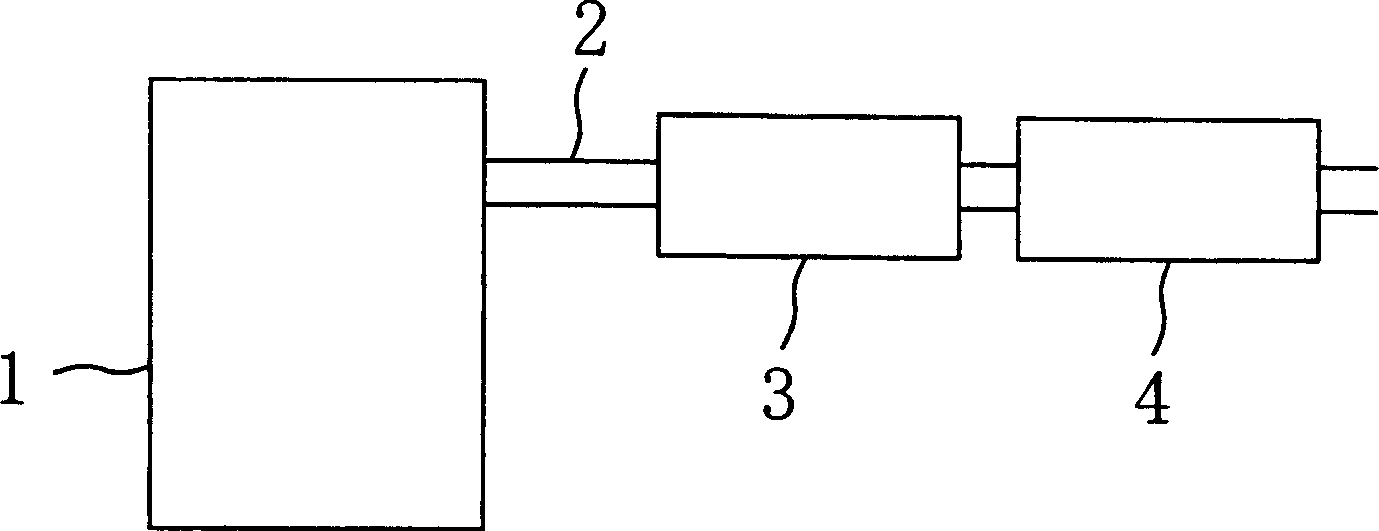

[0038] figure 1 Among them, 1 is the engine of the automobile, 2 is the exhaust gas discharge passage, 3 is the upstream side catalyst (three-way catalyst) arranged on the upstream side of the exhaust gas flow in the exhaust gas discharge passage 2, and 4 is the downstream catalyst (three-way catalyst) arranged on the downstream side. Side catalyst (three-way catalyst).

[0039]

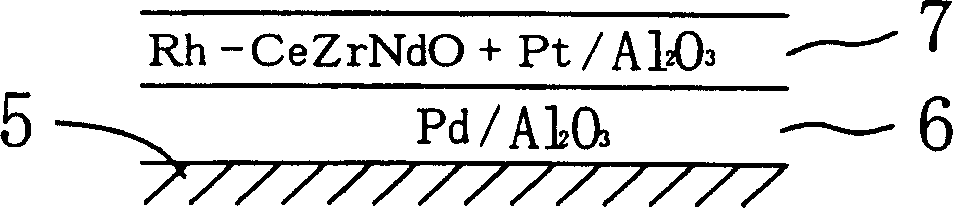

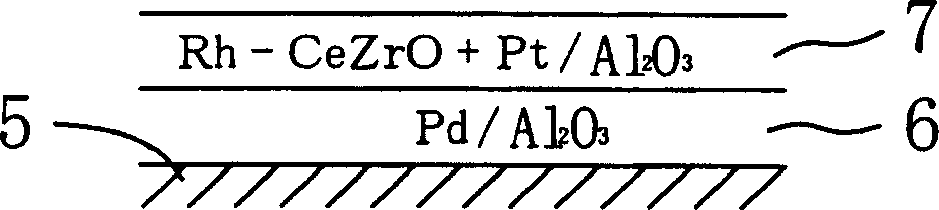

[0040] in order to figure 1 The respective catalyst devices constituting the Examples and Comparative Examples under the catalyst arrangement shown were prepared to produce Figure 2 to Figure 4 Three catalysts A, B, C are shown. Each of the catalysts is formed by laminating an inner catalyst layer 6 on the cell wall side and an outer catalyst layer 7 directly exposed to exhaust gas on a cell wall 5 of a honeycomb carrier (hereinafter referred to as carrier).

[0041] (for Cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com