Double-metal hand saw blade and its production process

A production method and bimetallic technology, applied in the direction of metal sawing equipment, metal processing equipment, sawing machine tools, etc., can solve the problems of high process requirements, high production costs, expensive prices, etc., and achieve good wear resistance and production Effects of cost reduction and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

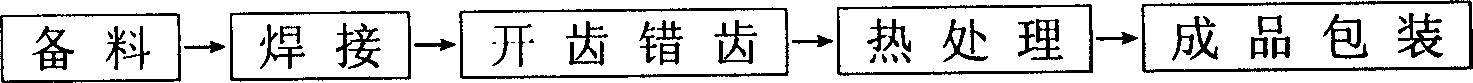

[0019] refer to figure 1 As shown, the production process steps of this embodiment are as follows:

[0020] (1) material preparation

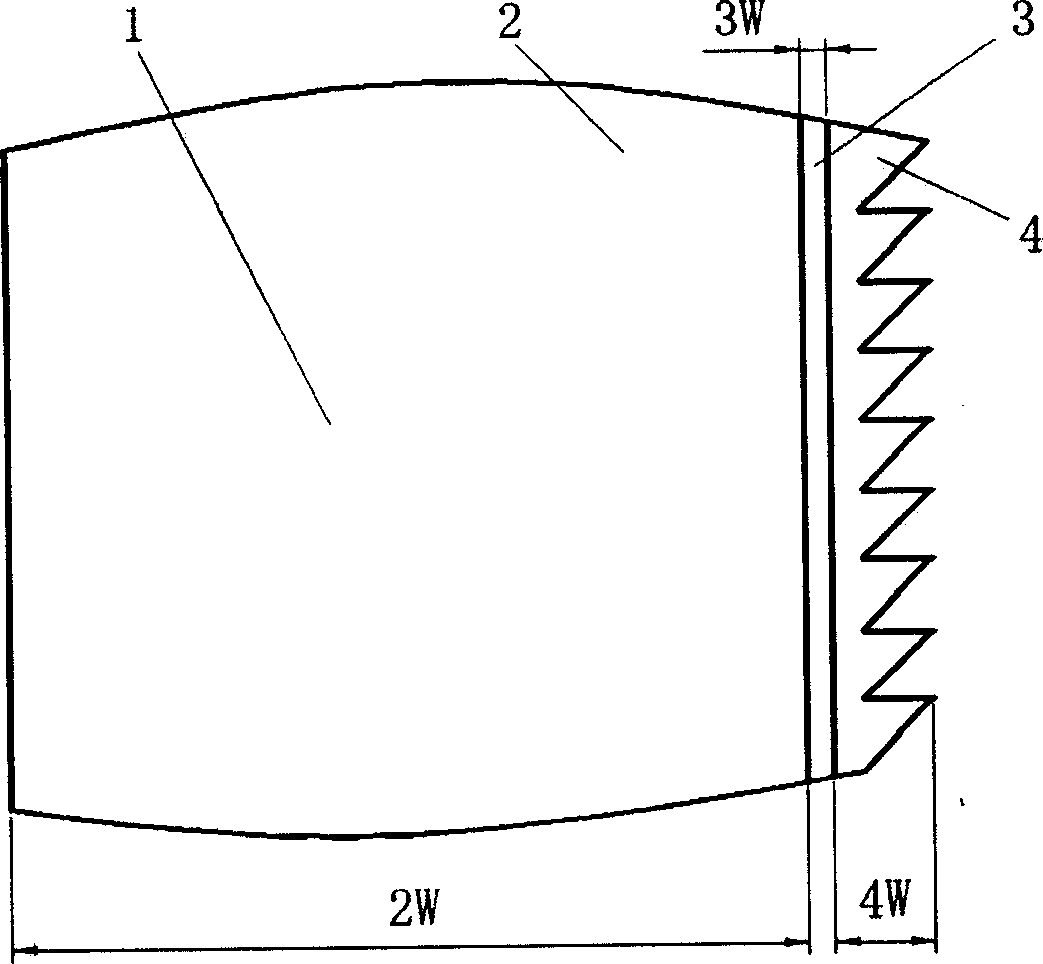

[0021] Such as figure 2 As shown, the finished product of this embodiment is a saw blade 1 with unilateral teeth, and its specification length is 300mm, width is 12mm, thickness is 0.6mm, and the tooth pitch is a standard tooth shape (0° rake angle) of 1.2mm. According to the requirements of the specification of the saw blade 1, the blanks of the saw back body 2 and the sawtooth body 4 of the specified size are prepared. Generally, the material of the saw body 2 is spring steel, such as 65Mn, 60Si2Mn, 50CrMnV, etc., and the material of the saw body 4 is high-speed tool steel, such as W6Mo5Cr4V2 (M2), W6Mo5Cr4V3 (M3), W4Mo2Cr4V (4241), W4Mo3Cr4V (4341), W9Mo3Cr4V (9341), etc., the present embodiment adopts 50CrMnV high-quality alloy spring steel as the material of the saw back body 2, and adopts W6Mo5Cr4V2 high-quality high-speed tool steel ...

Embodiment 2

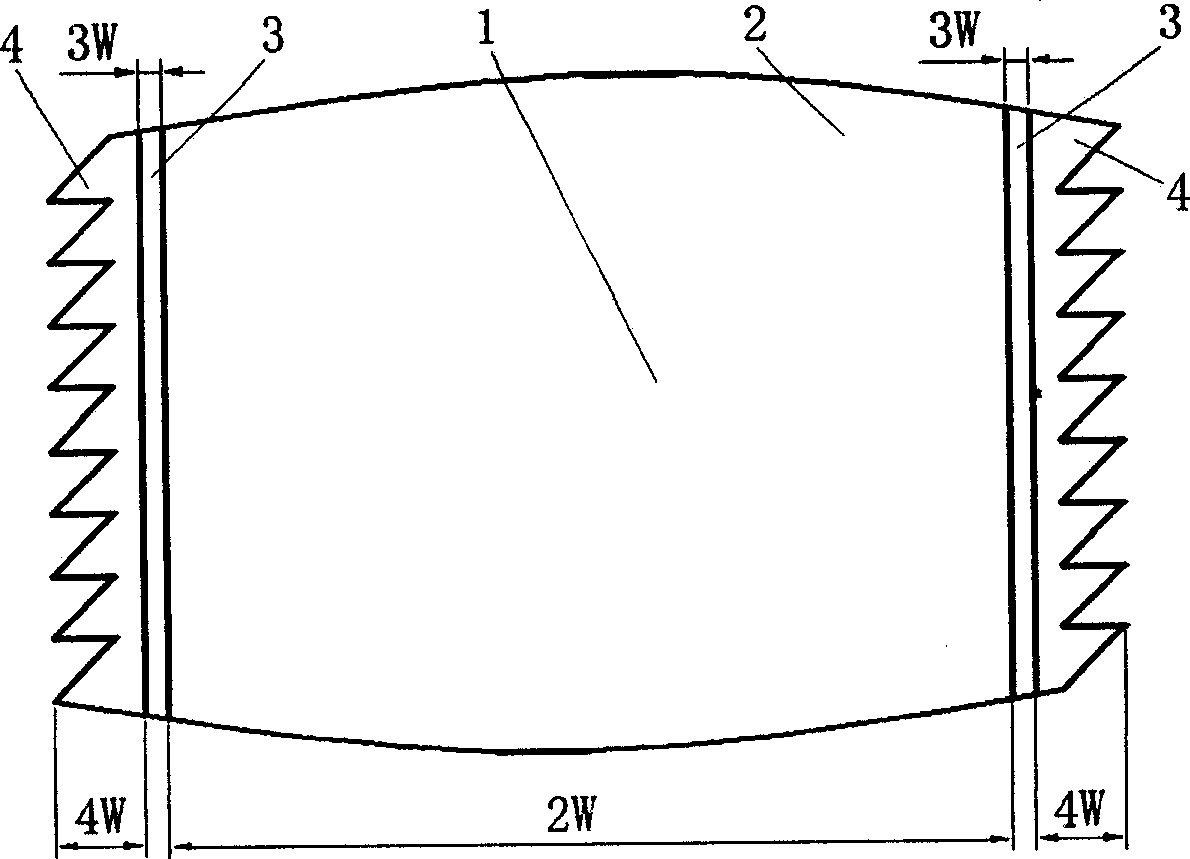

[0031] Such as image 3 As shown, the technical solution of this embodiment is basically similar to that of Embodiment 1, except that the finished product of this embodiment is a saw blade 1 with double-sided teeth. The hand-used saw blade width of bilateral opening tooth can be 12~65mm, and its specification width of present embodiment is 25mm, and length is 250mm, and thickness is 0.6mm, and pitch is 0.8mm standard tooth; According to the specification requirements of 1, prepare the blanks of the saw back body 2 and the saw tooth body 4 of the specified size. Generally, the saw back body width 2W of double-sided sawtooth is 45% to 94% of the width of the saw blade 1, and the saw tooth body width 4W is 3% to 30% of the width of the saw blade 1. The net saw back body width 2W of blanking in this embodiment is taken as 17.8mm 1. The single-piece net sawtooth body width 4W is 3mm, which is respectively 71.2% and 12% of the width of the saw blade 1, and is for use; Flat butt-we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap