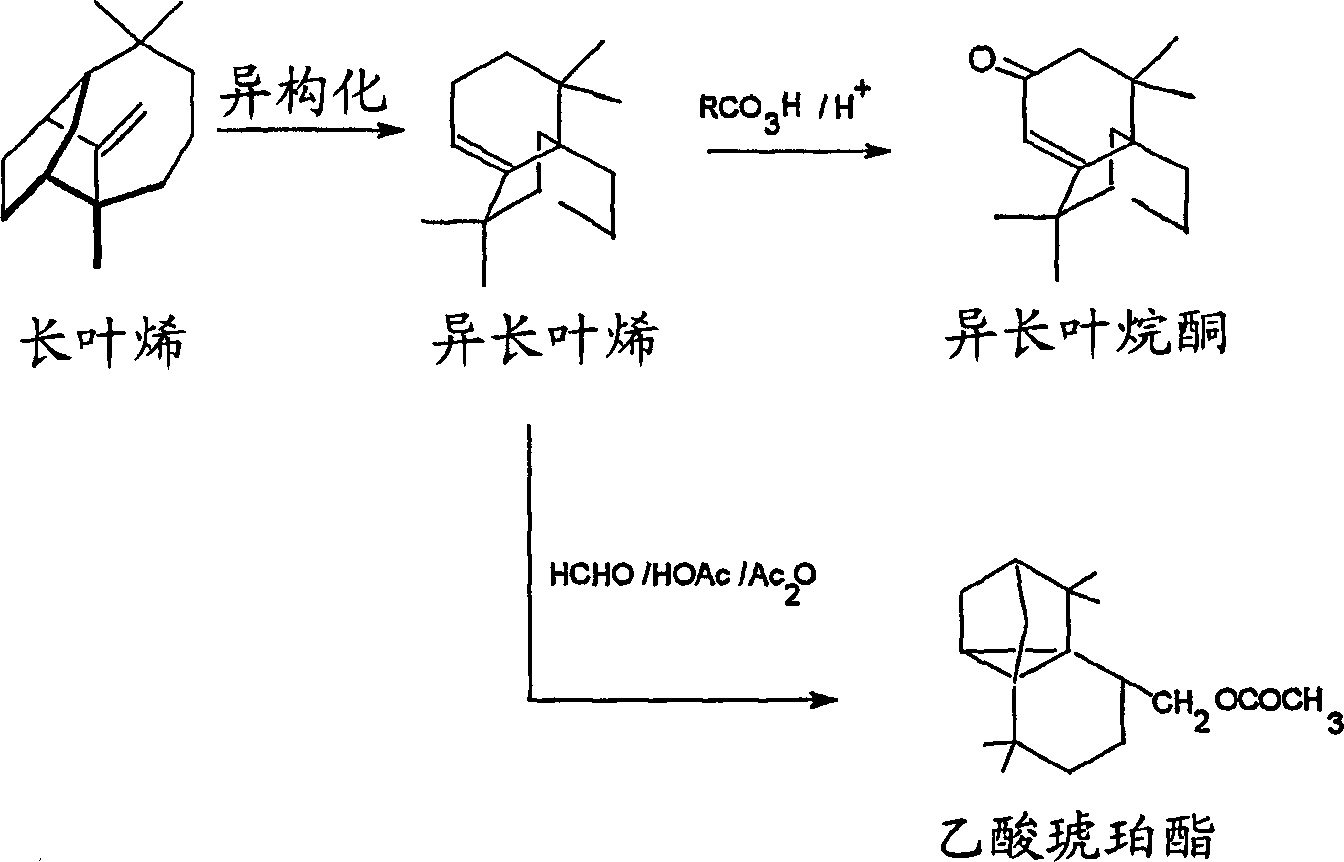

Catalytic process for the preparation of isolongifolene

A technology for isolongifolene and longifolene, which is applied in the field of catalysis for preparing isolongifolene, and can solve problems such as time-consuming, inability to meet large-scale production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 30% Zr(OC) dissolved in propanol or zirconium salt such as zirconium nitrate 3 h 7 ) 4 The solution was added dropwise with 6.4ml H 2 1.02 ml concentrated H diluted in O 2 SO 4 . The hydrolyzed sol was continuously stirred with a magnetic stirrer for 3 hours. The formed gel was first dried at room temperature for 3 hours and then at 110° C. for 12 hours. The dried gel was pulverized to 170 mesh and calcined at 600°C for 2 hours. The crystallite size of the prepared sample was determined to be 13 nm by X-ray diffraction. It was determined by elemental analysis that the sulfur supported on the catalyst was 1.2% by weight. Add 2 g of longifolene to a two necked round bottom flask immersed in an oil bath, the flask is equipped with a temperature controller, a magnetic stirrer, a condenser and a circulator. The temperature of the oil bath was slowly raised to the desired temperature, ie 120°C. To the reaction was added 0.2 gm of catalyst preactivated in a muffle fu...

Embodiment 2

[0055] Add 2 g of longifolene to a two necked round bottom flask immersed in an oil bath, the flask is equipped with a temperature controller, a magnetic stirrer, a condenser and a circulator. The temperature of the oil bath was slowly raised to the desired temperature, ie 140°C. To the reaction was added 0.2 gm of the catalyst prepared as described in Example 1 and preactivated in a muffle furnace at 450° C. for 2 hours. After 6 hours a sample was taken by means of a syringe and analyzed by gas chromatography using an HP-5 column. After 6 hours, the conversion of longifolene was 85% with a selectivity of 100%.

Embodiment 3

[0057] Add 2 g of longifolene to a two necked round bottom flask immersed in an oil bath, the flask is equipped with a temperature controller, a magnetic stirrer, a condenser and a circulator. The temperature of the oil bath was slowly raised to the desired temperature, ie 160 °C. To the reaction was added 0.2 gm of the catalyst prepared as described in Example 1 and preactivated in a muffle furnace at 450° C. for 2 hours. Samples were taken periodically over 2-6 hours by means of a syringe and analyzed by gas chromatography with an HP-5 column. After 2-6 hours, the conversion of longifolene was 84-86% with a selectivity of 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com