Air spring for low speed magnetic suspension train

A technology for maglev trains and air springs, applied in the directions of springs, hydraulic springs, springs/shock absorbers, etc., can solve the problems of unstable train operation, excessive horizontal, vertical and vertical displacement, and insecurity, and achieve vertical The effect of good longitudinal and lateral stiffness, good stability and reliability, and smooth running of the train

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

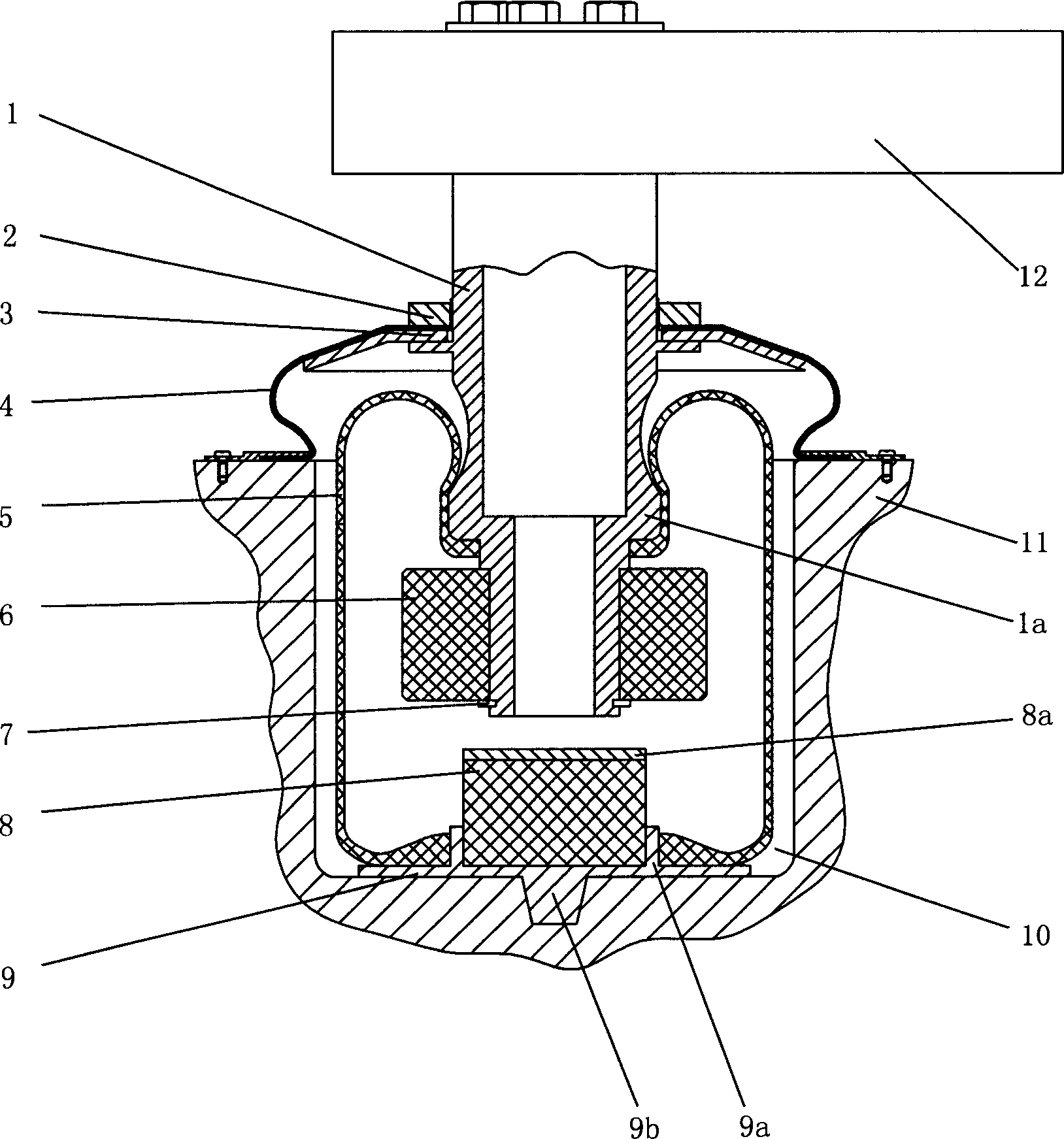

[0015] Accompanying drawing shows, a kind of specific embodiment of the present invention is: a kind of air spring that is used for low-speed maglev train, comprises air spring tube 1, rubber bag 5 and base 9, and the top of air spring tube 1 is fixed on the maglev train slide In the blind hole of the platform 12, the rubber bag 5 and the base 9 are placed in the blind hole 10 in the middle of the magnetic levitation frame 11 of the maglev train; 1a, the lower part of the rubber bladder 5 is sealed and fixed on the base 9, and the opening at the lower part of the rubber bladder 5 is clamped on the outer wall of the convex ring 9a in the middle of the base 9; the lower part of the air spring tube 1 is tightly fitted with a cylindrical flexible Horizontal stop 6, the lower part of the horizontal stop 6 is blocked by the retaining ring 7 embedded in the air spring tube 1; the convex ring 9a in the middle of the base 9 is embedded with a cylindrical flexible vertical stop 8. A bos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com