Tunable plasma resonant cavity

A plasma and resonant cavity technology, applied in the directions of plasma, gaseous chemical plating, coating, etc., can solve the problem of difficult to cope with the change of the equivalent load of the plasma resonant cavity, the inability to realize the real-time control of the plasma resonant cavity, and the cavity structure. The allowable variation range of size is narrow and other problems, so as to achieve the effect of small loss, simple structure and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

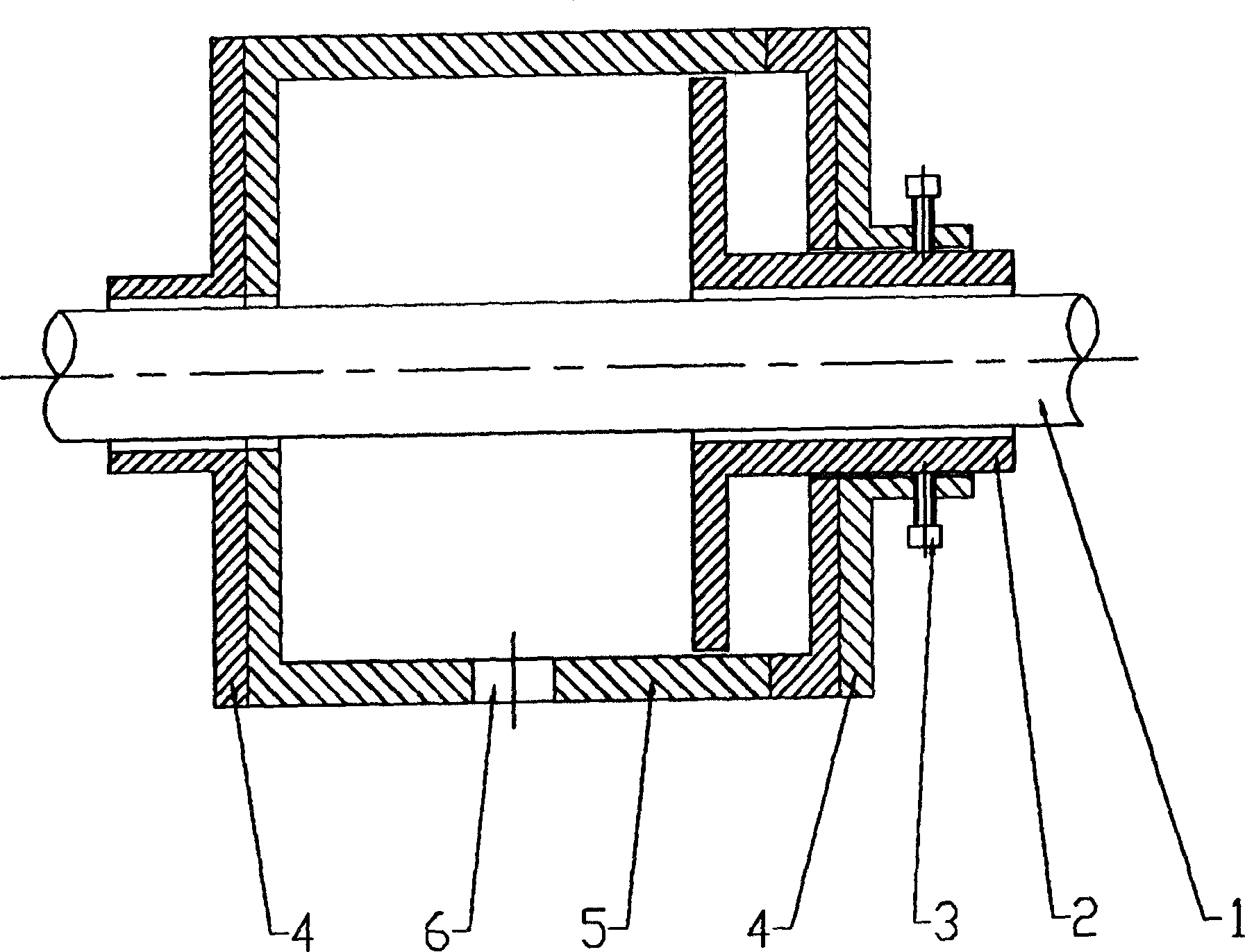

[0014] Embodiments of the present invention are further described below in conjunction with the accompanying drawings, including TE 011 The cylindrical resonant cavity housing 5 of the model cavity has an inner diameter of Ф150 mm to Ф220 mm and a length of 70 mm to 110 mm for electromagnetic waves of 2.45 GHz. There is a through hole 6 connected to the waveguide device in the circumferential direction of the cylindrical resonant cavity shell, cut-off waveguides 4 are set at both ends of the cylindrical resonant cavity shell, and a tuning piston 2 is installed at one end of the cylindrical resonant cavity cavity , the front end of the tuning piston is in the shape of a disc, and the extension part of the rear section is a hollow shaft with a small diameter. The hollow shaft of the extension part is slidingly arranged with the end hole of the resonant cavity shell, and the front end of the tuning piston extends into the cavity of the resonant cavity. The depth is 0-40mm, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com