Decorating material

A technology for decorative materials and substrates, applied in the field of decorative materials, can solve problems such as poor hand feeling, durability of concave parts, reduced pollution resistance, and inability to form concave parts with sufficient depth and clarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

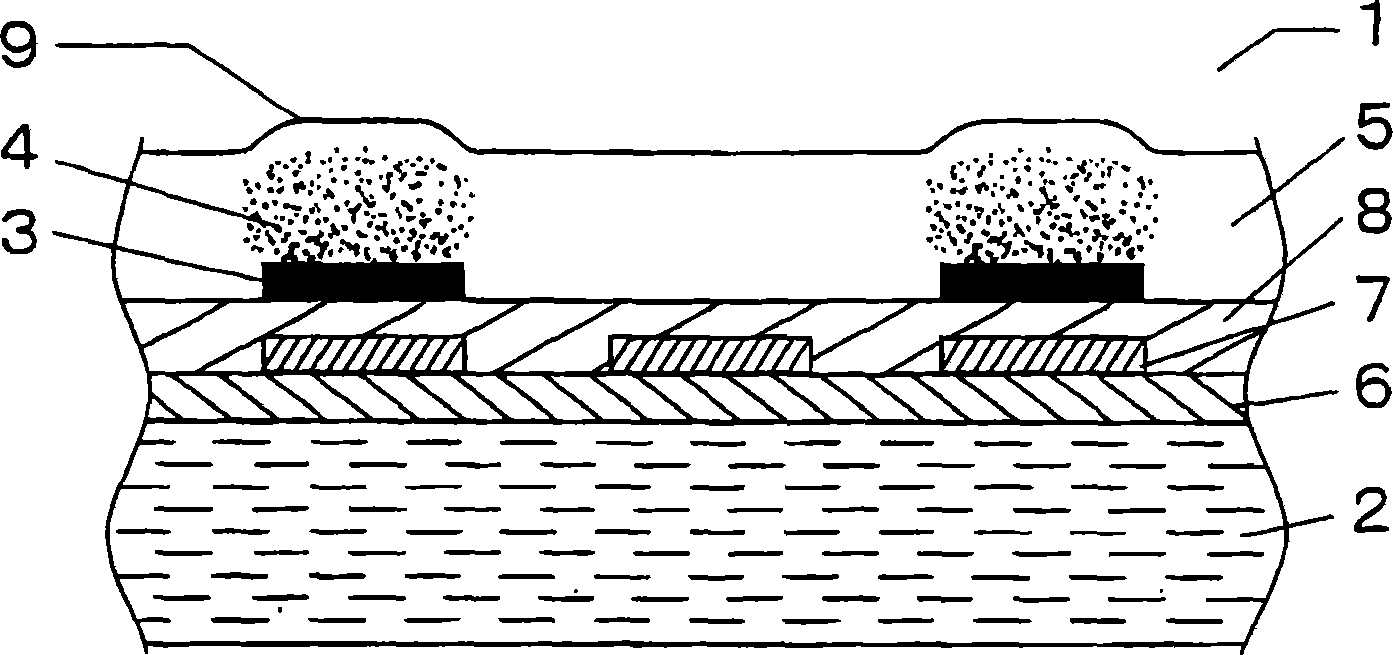

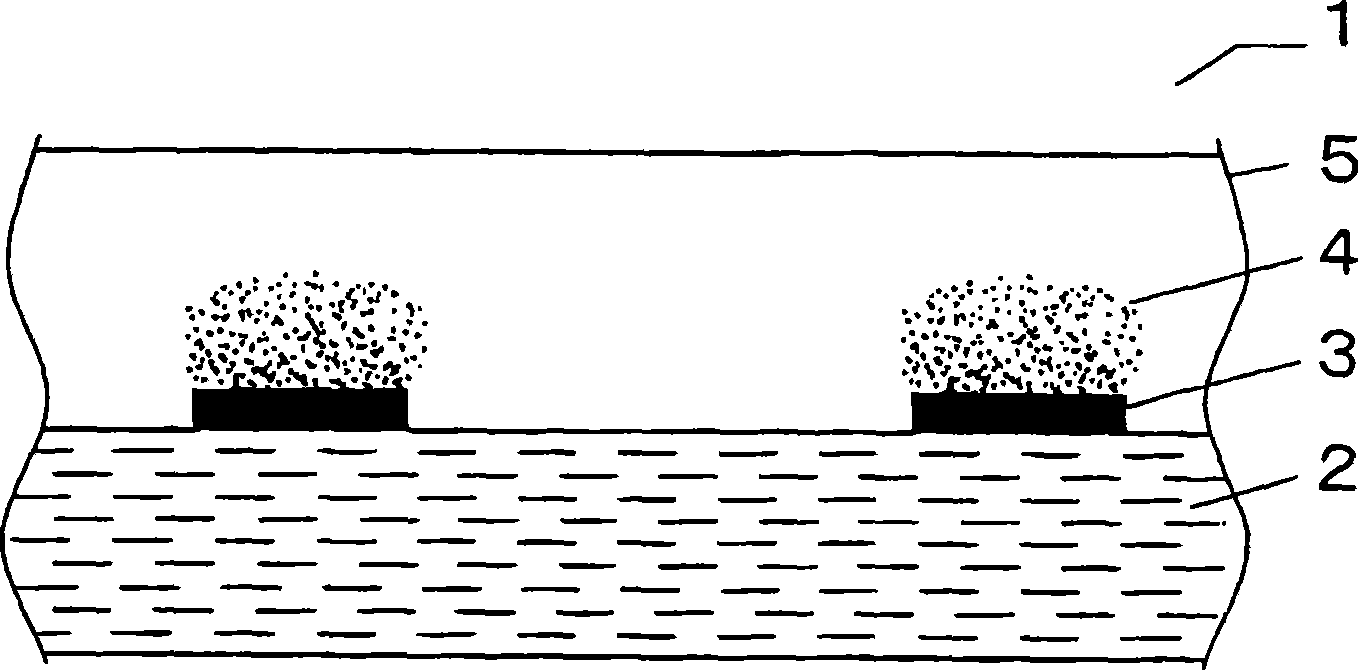

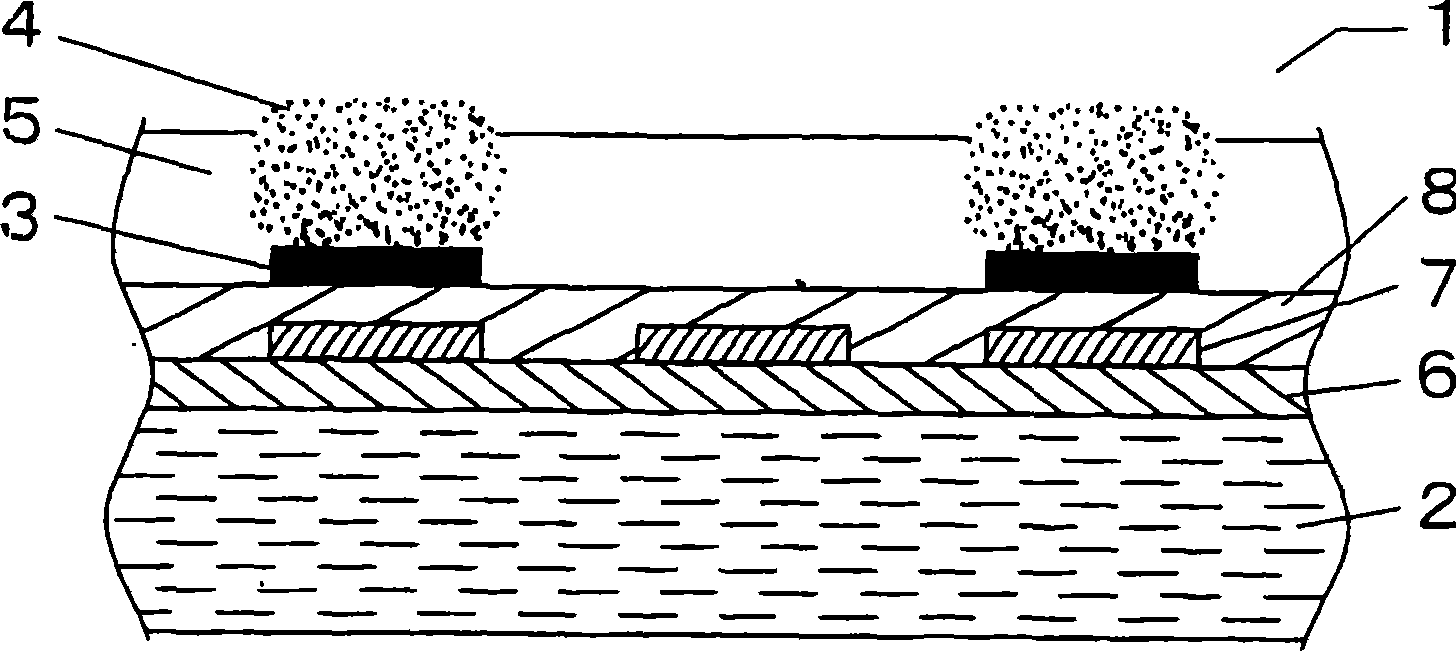

[0198] As the substrate 2, use the American standard weight per unit area of 30g / m 2 On one side of the inter-paper reinforced paper for building materials, acrylic resin and nitrocellulose are used as binders, titanium dioxide, iron oxide red, and chrome yellow are used as colorants, and the coating amount is 5g by gravure printing. / m 2 The (overall) layer forms the colored layer 6 . On top of it, use nitrocellulose as a binder and ink containing a colorant mainly composed of iron oxide red to form a pattern layer 7 of wood grain patterns by gravure printing.

[0199] Next, use the coating composition with a coating amount of 7g / m 2 Carry out gravure printing on the whole surface to form the anti-penetration layer 8 (primer layer). The coating composition used will be a polyester urethane resin with a number average molecular weight of 20,000 and a glass transition temperature (Tg) of -59.8 ° C. A polyisocyanate composed of methylene phenyl diisocyanate is used as a bin...

Embodiment 2

[0204] In the low-gloss pattern ink described in Example 1, a mixture of 90% by mass of polyester urethane resin and 10% by mass of unsaturated polyester resin was used as a binder resin, and as a colorant, A decorative material was obtained in the same manner as in Example 1, except that carbon black and red iron oxide were added to color a dark brown colorant.

[0205] The decorative material was evaluated for gloss, water resistance, peelability over time, stain resistance, and marring performance. Table 1 shows the results.

[0206] For the decorative material obtained in Example 1 and Example 2, observe its cross-section with a microscope magnification, and observe: the low-gloss state of the low-gloss pattern ink layer in the surface protection layer and its vicinity become scattered light, and in addition , the other surface layers do not scatter light and become highly transparent. In addition, when the decorative material was visually observed from the surface prote...

Embodiment 3

[0208] Except having made the silica particle of 5 micrometers of average particle diameters into 8 mass parts in an electron beam curable resin composition, it carried out similarly to Example 1, and obtained the decoration material.

[0209] The decorative material was evaluated for gloss, water resistance, peelability over time, stain resistance, and marring performance. Table 1 shows the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com