Crystallizing separating tech. of nitro methyl-phenoxide mixture

A technology of nitroanisole and p-nitroanisole is applied in the field of fine chemical industry, can solve problems such as prolonging crystallization time, and achieve the effects of increasing investment and operating costs, improving operating environment, and reducing the degree of equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

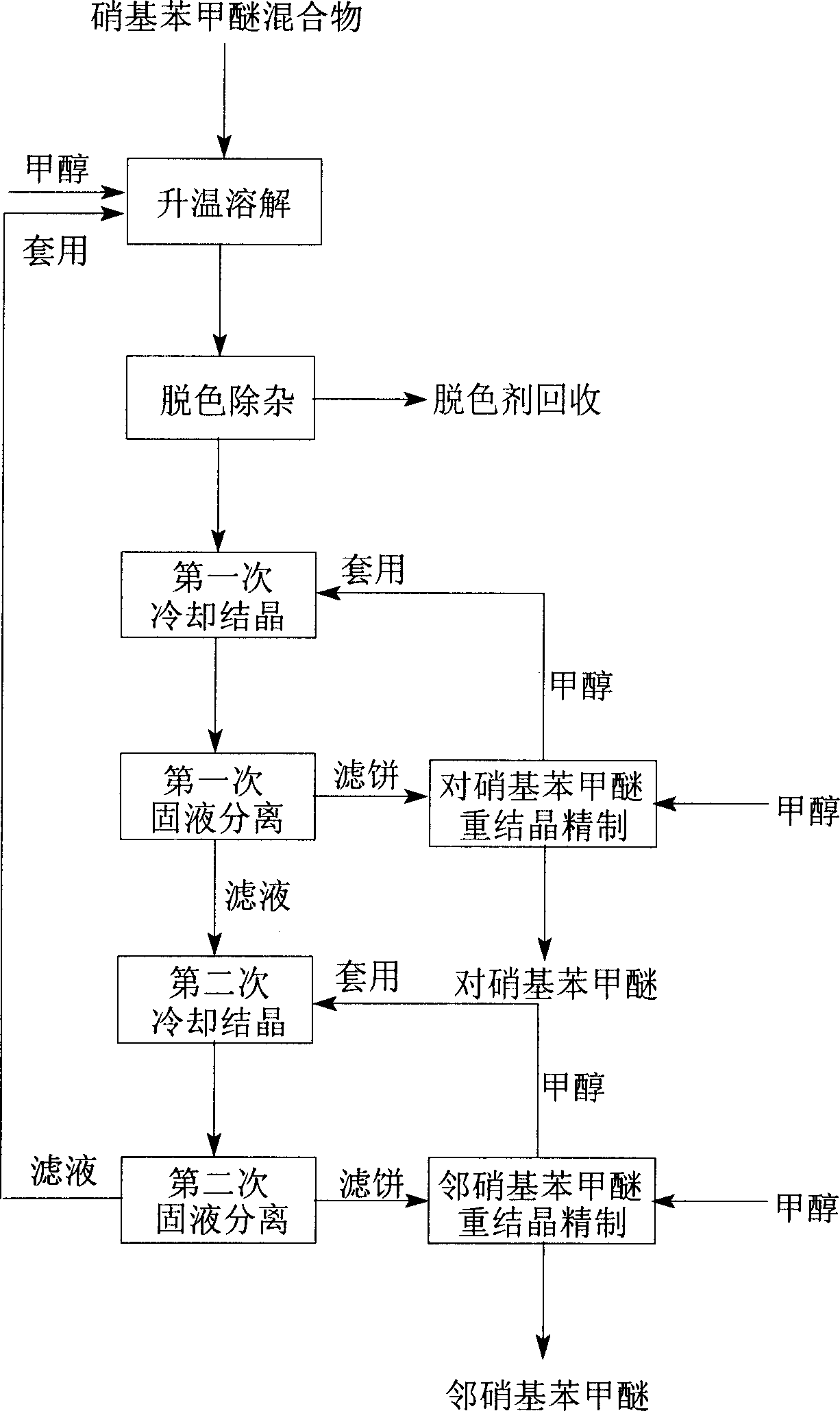

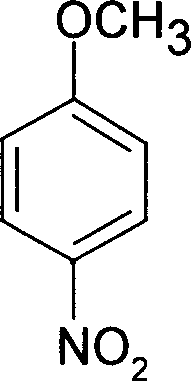

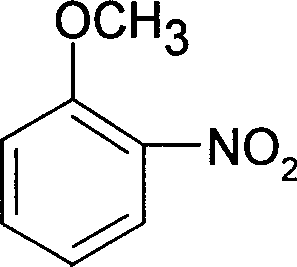

[0033] As shown in the figure, a kind of nitroanisole mixture is raw material, the separation process of producing p-nitroanisole and o-nitroanisole.

[0034] In the stirring and dissolving kettle, add nitroanisole mixture (the content of o-nitroanisole, m-nitroanisole mixture is respectively 40% and 56%) and methyl alcohol, the content of nitroanisole mixture and methyl alcohol The ratio is: 400g: 500ml. Under stirring conditions, heat up to methanol reflux temperature to dissolve the material; add molecular sieve adsorbent to the dissolved material for decolorization and impurity removal operation, filter while it is hot, and the filtrate enters the first cooling crystallization kettle; In the first cooling crystallizer, the refined material is cooled to 13°C, p-nitroanisole is crystallized and separated, filtered, the filtrate enters the second cooling crystallization kettle, and the filter cake enters the p-nitroanisole recrystallizer; In the cooling crystallizer for the s...

Embodiment 2

[0036] Recrystallization Separation Experiment of o-Nitroanisole and p-Nitroanisole in Methanol Solution

[0037] Add 500ml of methanol into the flask, add 300g of nitroanisole mixture at room temperature, and heat slowly. During the heating process, observe the phenomenon: when the temperature rises to 40°C, the mixed ether is almost completely dissolved; continue to heat up to 60°C, the solution It is a brown homogeneous solution; reflux at 60°C for 30 minutes, slowly cool down, and stand at 40°C for more than 6 hours without solid precipitation; continue to cool down, and when the temperature drops to 18.5°C, needle-shaped crystals begin to precipitate , the temperature dropped to 13° C. and stood still at 13° C. for 10 hours, and the precipitated solid was suction-filtered and weighed to obtain 132 g of light yellow needle-like crystals. Then lower the temperature to 5°C, let it stand for 6 hours at 5°C, and heat-preserve and filter to obtain a crystallization amount of 58...

Embodiment 3

[0039] Recrystallization and separation of p-nitroanisole in methanol solution: heat the primary crystallization product obtained by filtration at 13°C to methanol in different ratios to 60°C, and reflux at 60°C for 30 minutes, and slowly cool down until the temperature drops to 60°C. to 13°C, stand at 13°C for a certain period of time, filter the precipitated solid with suction and weigh to obtain light yellow needle-like crystals. Then continue to lower the temperature to 5°C, let stand at 5°C for a certain period of time, filter, and weigh the obtained crystals. See Table 2 for the phenomena and results.

[0040] The primary crystallization product obtained by filtration at 5°C is heated up to 15°C according to the ratio of raw material to methanol: 300g: 500ml, heated to 15°C for dissolution, slowly lowered to 5°C and left to stand for 10 hours, filtered to obtain the weight of the crystallized product, the phenomenon is similar to The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com