Method and apparatus for preparing camphene using light oil of pine tar

A technology for pine oil and camphene, which is applied in the directions of hydrocarbon cracking to produce hydrocarbons, organic chemistry, etc., can solve the problems of high price of raw material turpentine, unseen preparation of camphene, high production cost, etc., and achieves low raw material price and high production cost. The effect of low cost and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

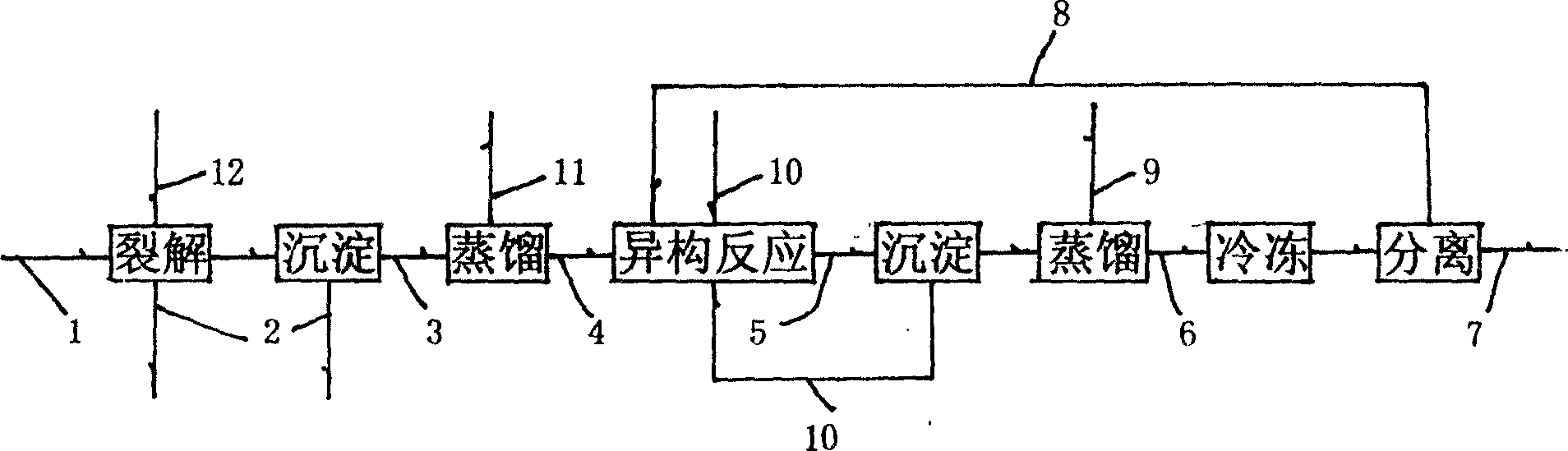

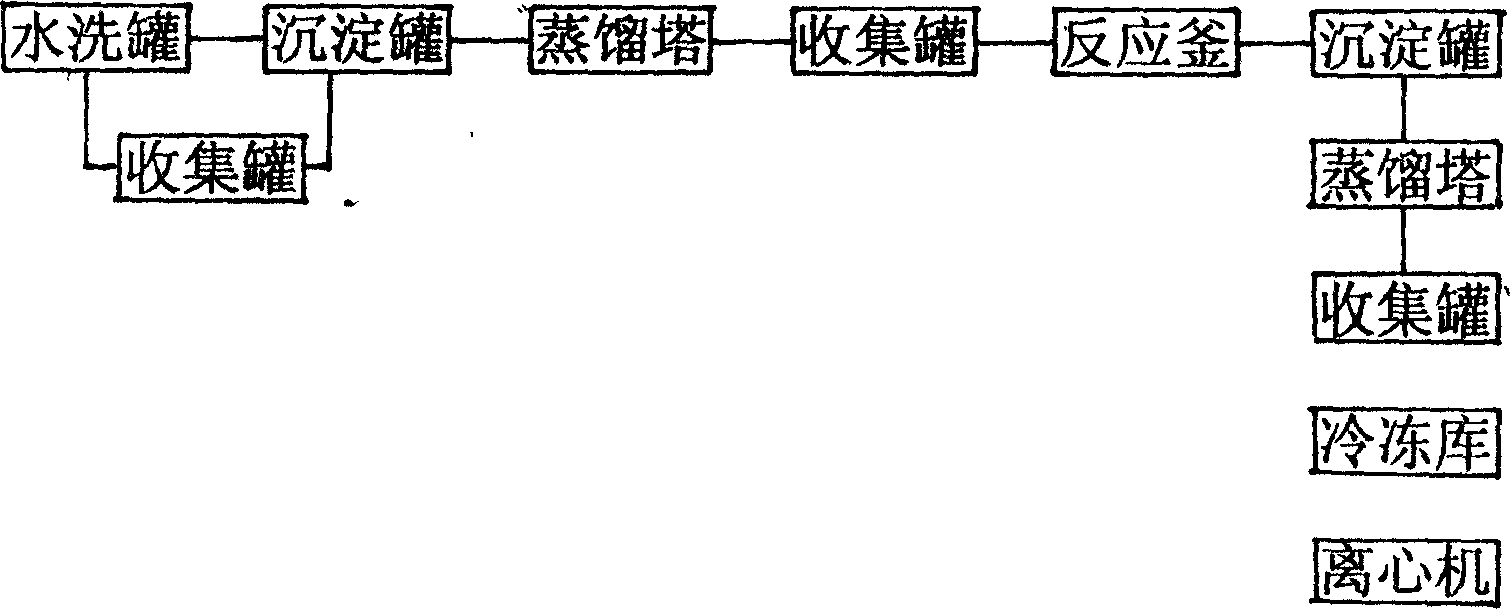

[0071] The following sequential steps: a. Put pine light oil 1 into a water washing tank, then add cracking agent 12, and raise the temperature to 40-70° C. to crack pine light oil 1, and separate phenolic water 2 and dry distilled oil 3; b. The dry distillation oil 3 is introduced into the precipitation tank, left to settle, and the residual phenolic water 2 and the dry distillation oil 3 are separated; c. The precipitated dry distillation oil 3 is introduced into the distillation tower, and is carried out under a vacuum of 0.91-0.94Pa and a temperature of 85-125°C. Distillation, separation of head oil 11 and middle oil 4: d. Import middle oil 4 into the reactor and add catalyst 10, carry out isomerization reaction at normal pressure and temperature of 130-140°C, the reaction time is 18-24 hours, and the output contains catalyst The isomerized liquid 5 of 10; e. the isomerized liquid 5 containing the catalyst 10 is introduced into a settling tank for static precipitation, and ...

Embodiment 2

[0073] The sequential steps and equipment are the same as in Example 1, except that the separated liquid miscellaneous oil 8 is returned to the reactor for isomerization reaction. It is detected that the prepared camphene 7 contains 93.25% of the single camphene, and the product yield reaches 80%.

Embodiment 3

[0075] The sequential steps and equipment are the same as in Example 1, except that the precipitated catalyst 10 is returned to the reactor for recycling, and only some catalysts 10 need to be replenished in the reactor according to the output, which obviously reduces the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com