Pigment carbon black neutral pen ink and its preparation method

A gel pen ink, carbon black technology, applied in ink, home utensils, applications, etc., to achieve the effects of good writing performance, long cap removal time, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

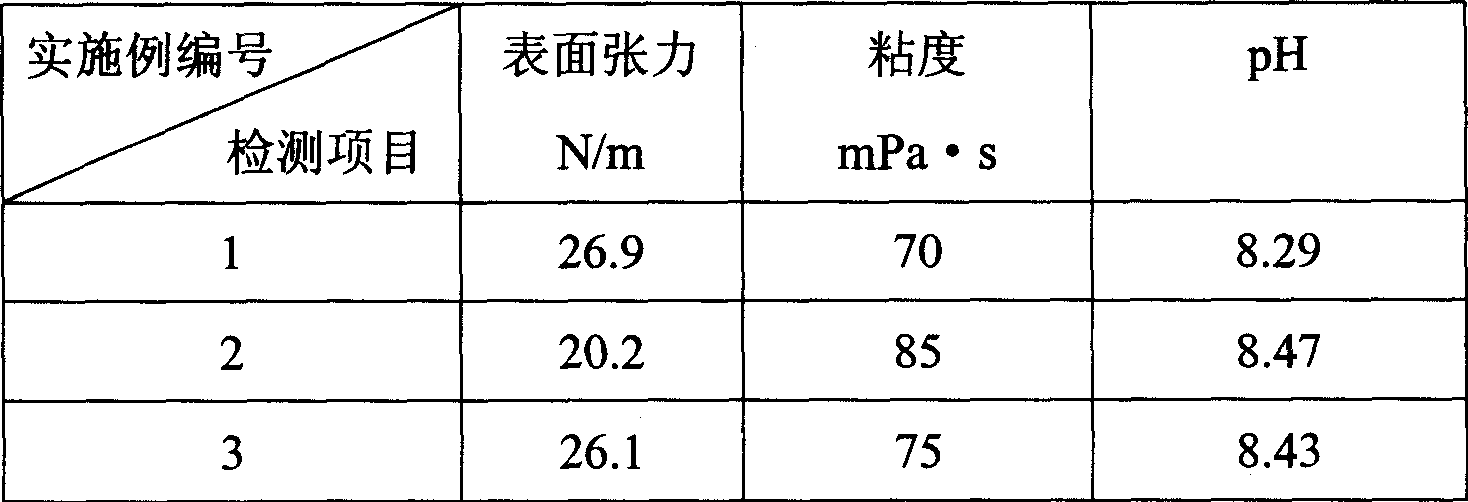

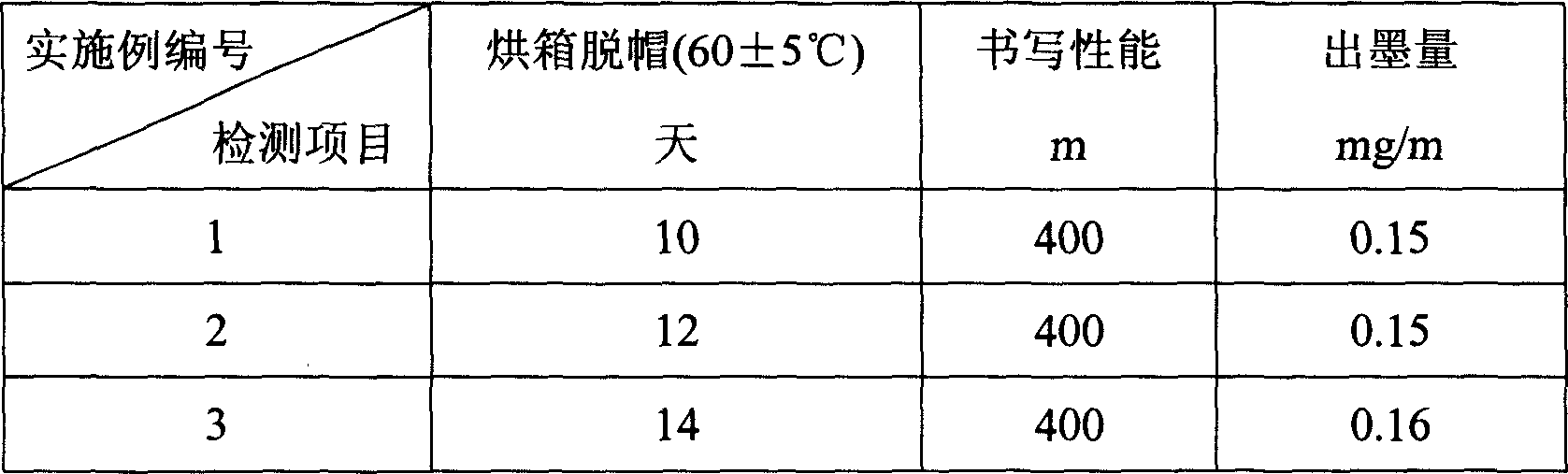

Examples

Embodiment 1

[0028] According to the formula listed below and the above-mentioned preparation process, the black gel pen ink with excellent performance can be obtained.

[0029] Component name Mass (%)

[0030] Carbon black paste 1 30

[0031] Alkali-swellable thickener 2

[0032] Amylopectin 2

[0033] Ethylene glycol 10

[0034] Propylene Glycol 8

[0035] Triethanolamine 2

[0036] Calcium sorbate 1

[0037] Phosphate 1

[0038] Oleyl alcohol 2

[0039] Deionized water 42

[0040] Among them: carbon black paste 1 is GS-590 carbon black paste from Xiamen Jinshang Resin Co., Ltd.

Embodiment 2

[0041] Example 2: Different color pastes are used, and after the formula is adjusted appropriately, the same preparation process as in Example 1 can be used to obtain an ink with excellent performance.

[0042] Component name Mass (%)

[0043] Carbon black paste 2 30

[0044] Alkali Swellable Thickener 4

[0045] Dextrin 5

[0046] 1,3-Butanediol 10

[0047] Glycerol 10

[0049] Sodium Benzoate 1

[0050] Benzotriazole 1

[0051]Lauric acid 1

[0052] Deionized water 36

[0053] Among them, carbon black paste 2 is #234 carbon black paste of Shanghai Ink Factory of Shanghai Haiwen (Group) Co., Ltd.

Embodiment 3

[0054] Example 3: Different color pastes are used, and after the formula is adjusted appropriately, the same preparation process as in Example 1 can be used to obtain an ink with excellent performance.

[0055] Component name Mass (%)

[0056] Carbon black paste 3 35

[0057] Alkali Swellable Thickener 4

[0058] Maltose Cyclodextrin 2

[0059] Ethylene glycol ether 10

[0060] Triethylene glycol 10

[0061] Sodium bicarbonate 2

[0062] Sodium pentachlorophenate 1

[0063] Tolyltriazole 1

[0064] OP 2

[0065] Deionized water 33

[0066] Among them, carbon black paste 3 is a self-made color paste, and its preparation process is as follows: select 6# pigment carbon black (Nanjing Meishan Yiteng Chemical Co., Ltd.) 20%, dispersant (BYK-163) 2%, 1,3-propylene glycol 10% %, polyethylene glycol (av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com