Process for preparing vapor doping zone-melted silicon single crystal

A production method, gas-phase doping technology, which is applied in the production field of molten silicon single crystal in the gas-phase doping area, and can solve the problem of high axial resistivity inhomogeneity of silicon single crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

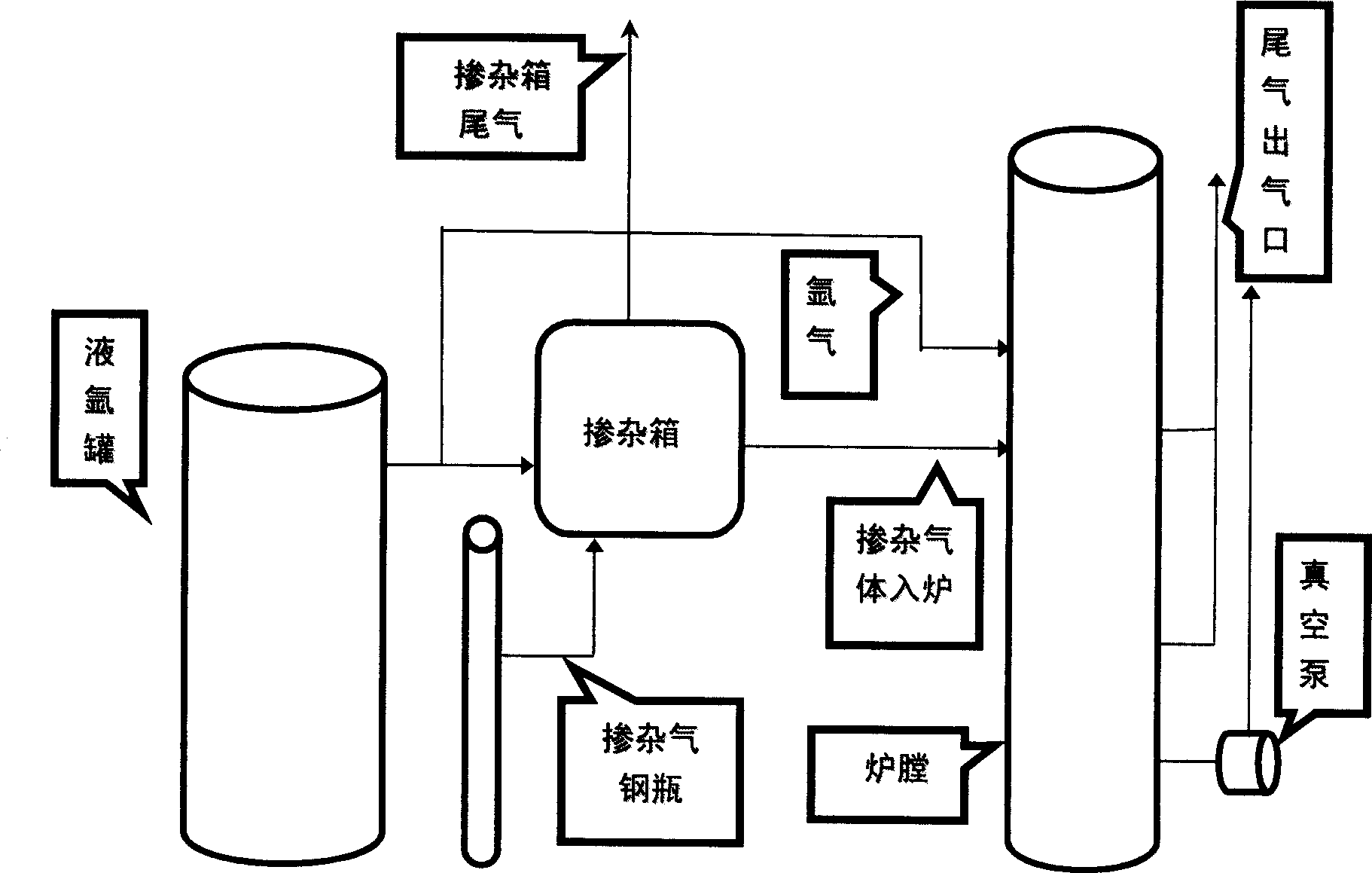

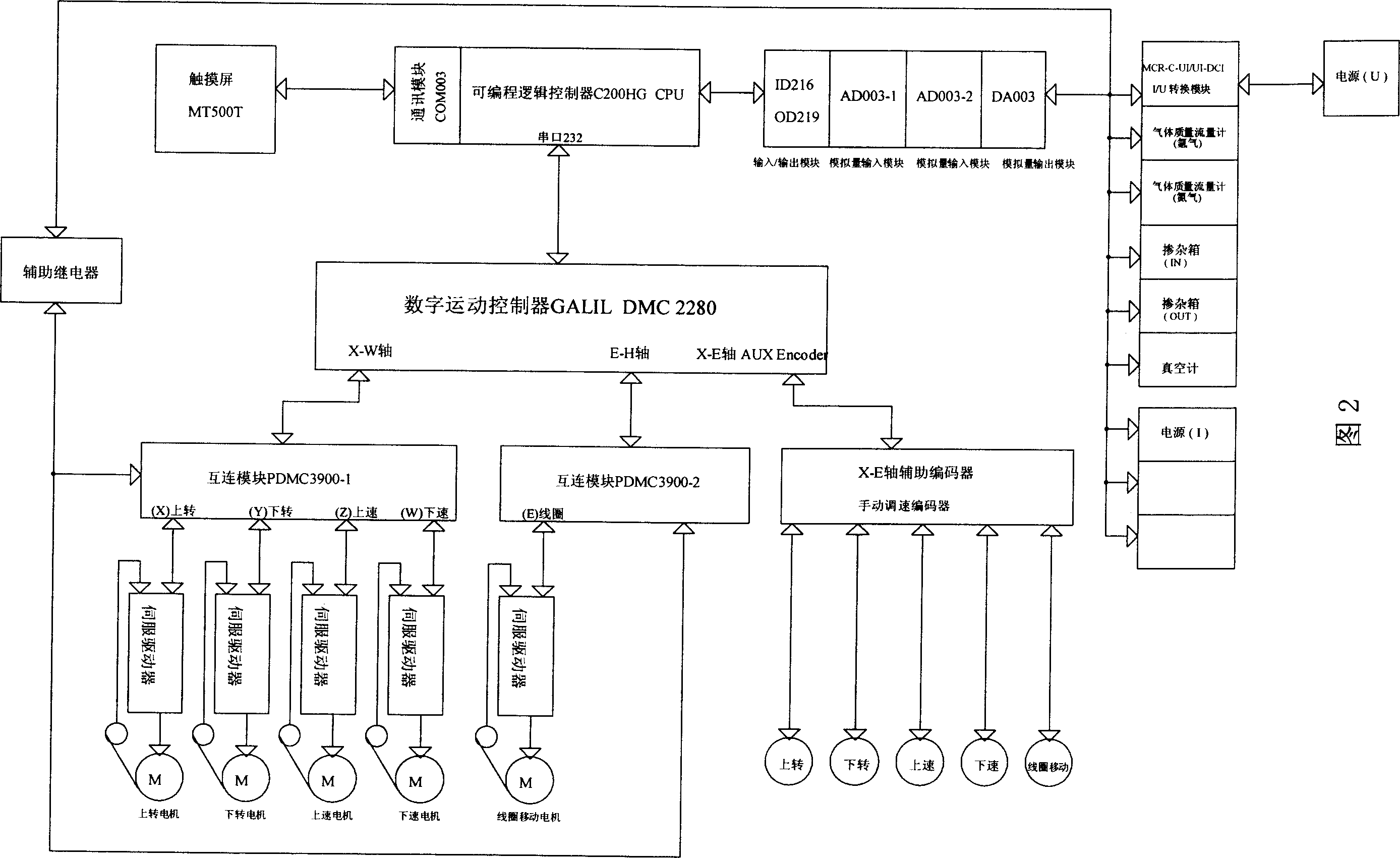

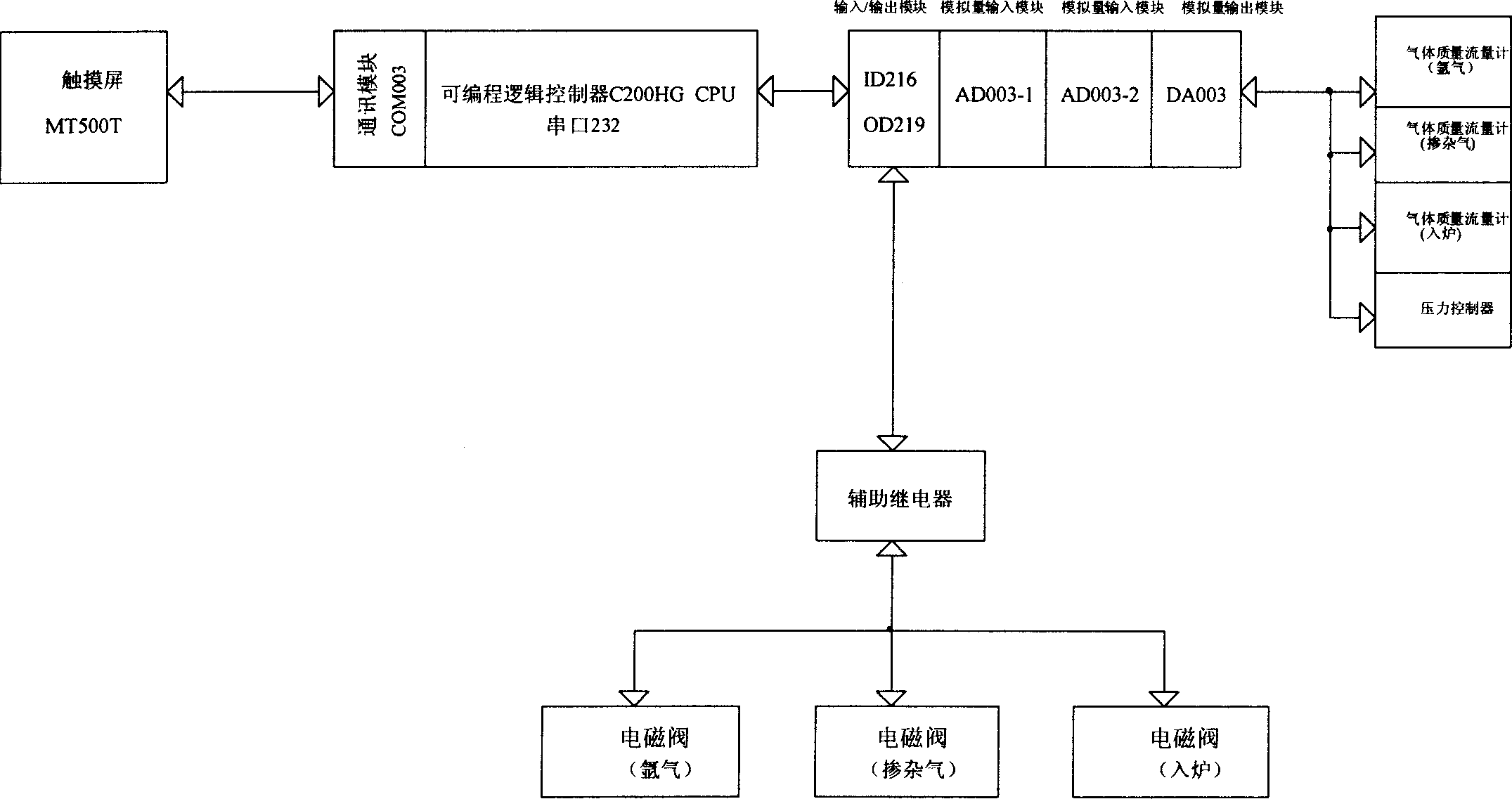

[0015] refer to figure 1 , 2, 3. In the described evacuation and inflation process, the relative pressure of the furnace pressure is 0.2bar-6bar; The speed is 1mm / min-5mm / min, and the rotation speed of the lower shaft maintained at equal diameter is 1rpm-30rpm. In the described doping process, the doping gas used is phosphine (PH 3 ), borane (B 2 h 6 ), phosphine (PH 3 ) and argon (Ar) mixed gas, borane (B 2 h 6 ) mixed with argon (Ar) any one of the four doping gases; among the four doping gases, phosphine (PH 3 ) or borane (B 2 h 6 ) accounts for a concentration ratio of 0.0001%-100%.

[0016] In the evacuation process, the use of furnace pressure is determined according to the diameter of the silicon single crystal. Example: 3" single crystal uses 0.5bar (relative pressure), while 4" single crystal uses 1bar (relative pressure).

[0017] The doping gas used in the doping process includes four kinds: 1. Phosphine (PH 3 ) its concentration is 100%, 2. borane (B 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com