Carbon black filtering and electric direct-heating type regeneration device for diesel truck

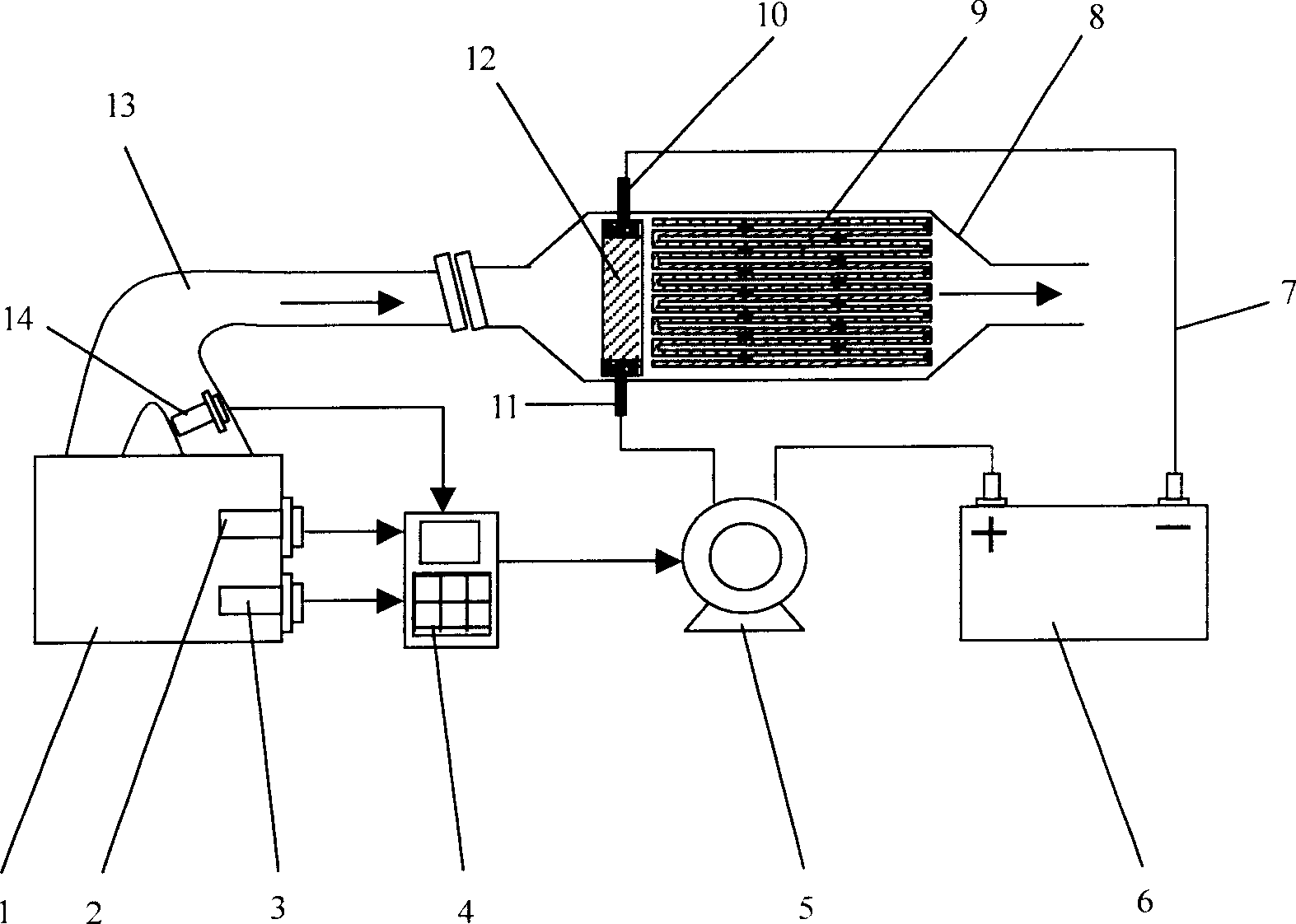

A technology for regeneration devices and diesel vehicles, which is applied to mufflers, exhaust devices, engine components, etc., can solve problems such as difficulty in promotion and complicated structure of traps, and can increase the filter area, reduce the dead angle of regeneration, and increase the probability of collision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation process of diesel vehicle soot filter-electric direct heat regeneration device is as follows:

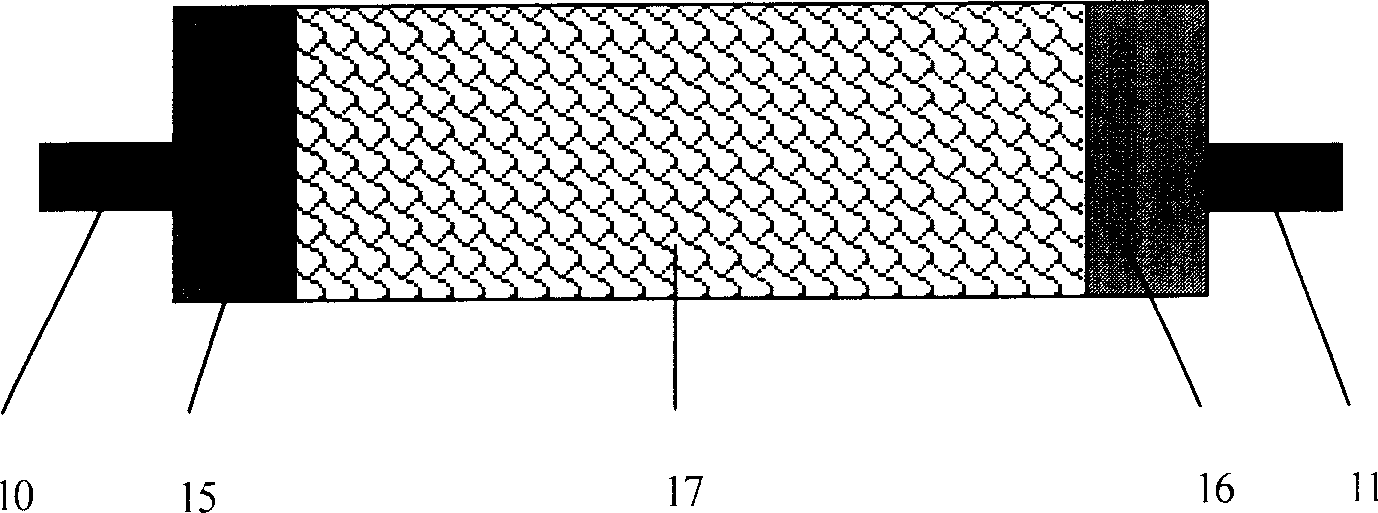

[0043] ① Using conductive silicon carbide foam ceramics made according to "A High-Strength and Dense Foamed Silicon Carbide Ceramic Material and Its Preparation Method" (applied by the Institute of Metal Research, Chinese Academy of Sciences, application number 03134039.3, application date: 030922) as diesel vehicle soot Filtration-filter body (foam ceramic main filter) and heating body (electric direct heating heating element) materials of electric direct heating regeneration device.

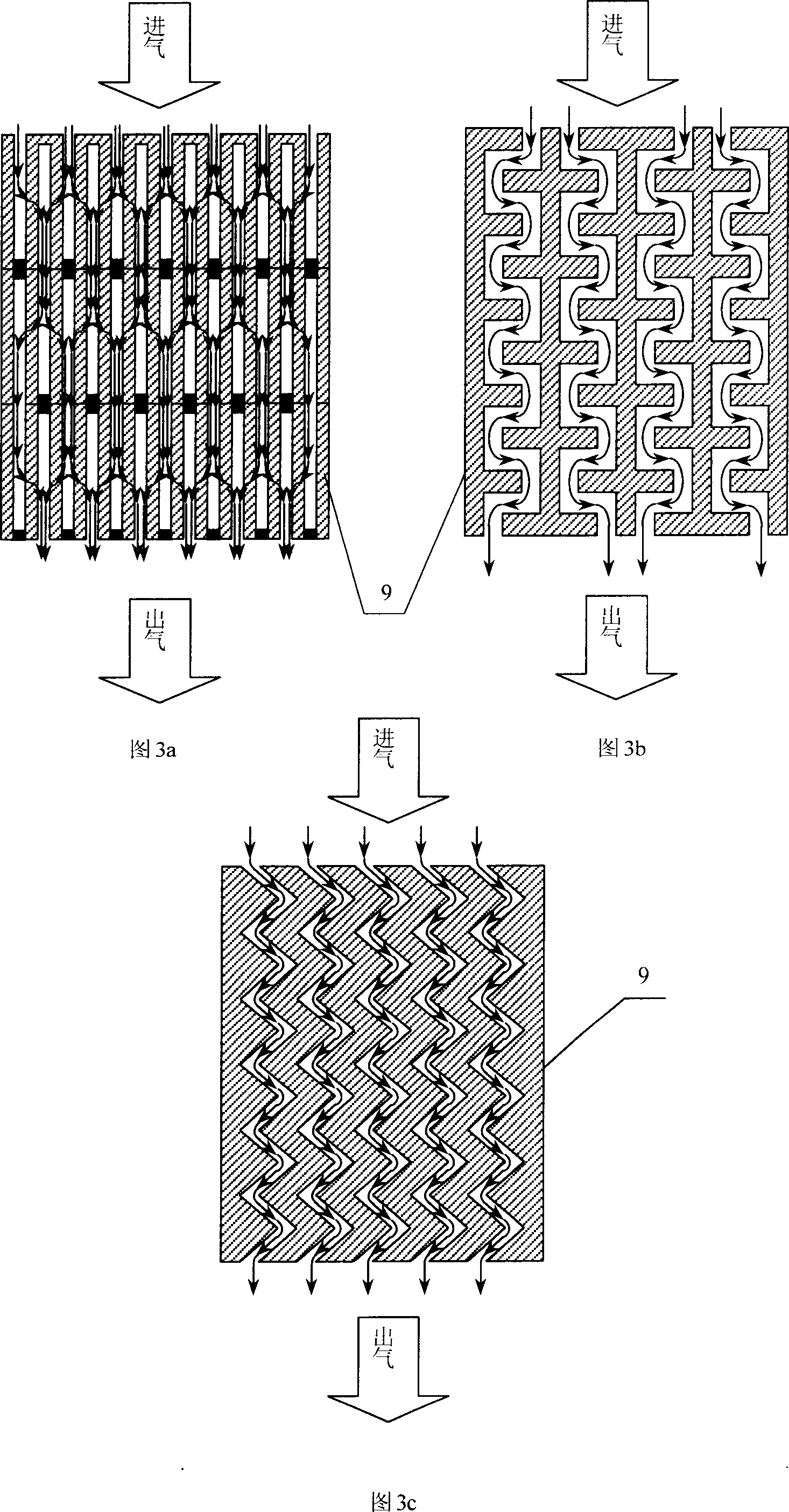

[0044] ②Process the ceramic foam material into a wall-flow structure, "king" or "sawtooth" shape as shown in Figure 3a-c, and use it as the main filter of the soot filter-electric direct heating regeneration device for diesel vehicles. The main filter has several meandering airflow passages, the volume of the main filter and the number and width of the passages can be adjusted ...

Embodiment 1

[0066] ① Take conductive silicon carbide foam ceramics 100×40×20mm, soak them in NaOH solution with a concentration of 3M for 8 minutes, remove oil stains and other impurities on the surface, then wash them with water, and then dry them in an air atmosphere at 120°C for 2 hours;

[0067] ②Take two pieces of graphite 10×40×20mm, and braze them to the two ends of the foamed silicon carbide ceramics mentioned in ①, as the base of the metal electrode;

[0068] ③ Brazing two stainless steel columns with a diameter of 6mm on the graphite base as electrodes connected to the wire;

[0069] ④ As shown in Figure 3a, the conductive silicon carbide foam ceramics are assembled into a wall-flow structure main filter with a volume of 2 liters;

[0070] ⑤ Connect the electric heating element and the main filter according to Figure 4a Packaged into a centralized heating diesel vehicle soot filter-electric direct heat regeneration device;

[0071] ⑥ The engine model used in the test is SOFIM...

Embodiment 2

[0073] The difference from Example 1 is:

[0074] Before the test, install the diesel vehicle soot filter-electric direct thermal regeneration device at the designated position of the diesel engine exhaust passage, keep the engine speed at 2160rpm, torque at 188Nm, and power at 42.5kW for 5 hours to filter the diesel vehicle soot -The electric direct heat regeneration device fully accumulates soot, then connects the electric direct heat heating circuit, and uses the on-board 12V battery to supply power for electric direct heat regeneration. After the regeneration, the diesel engine 13 operating condition test with the embodiment 1 was carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com