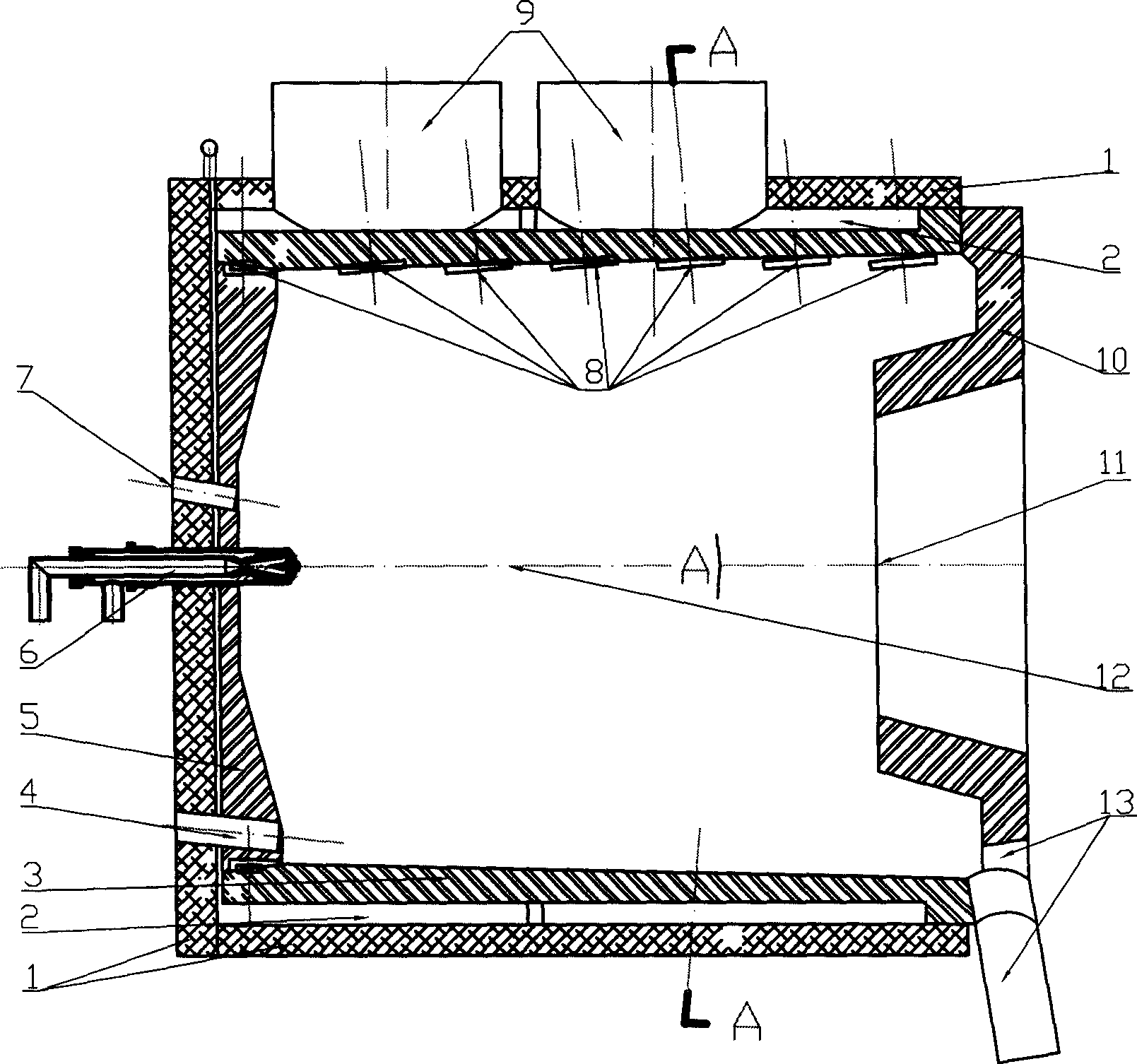

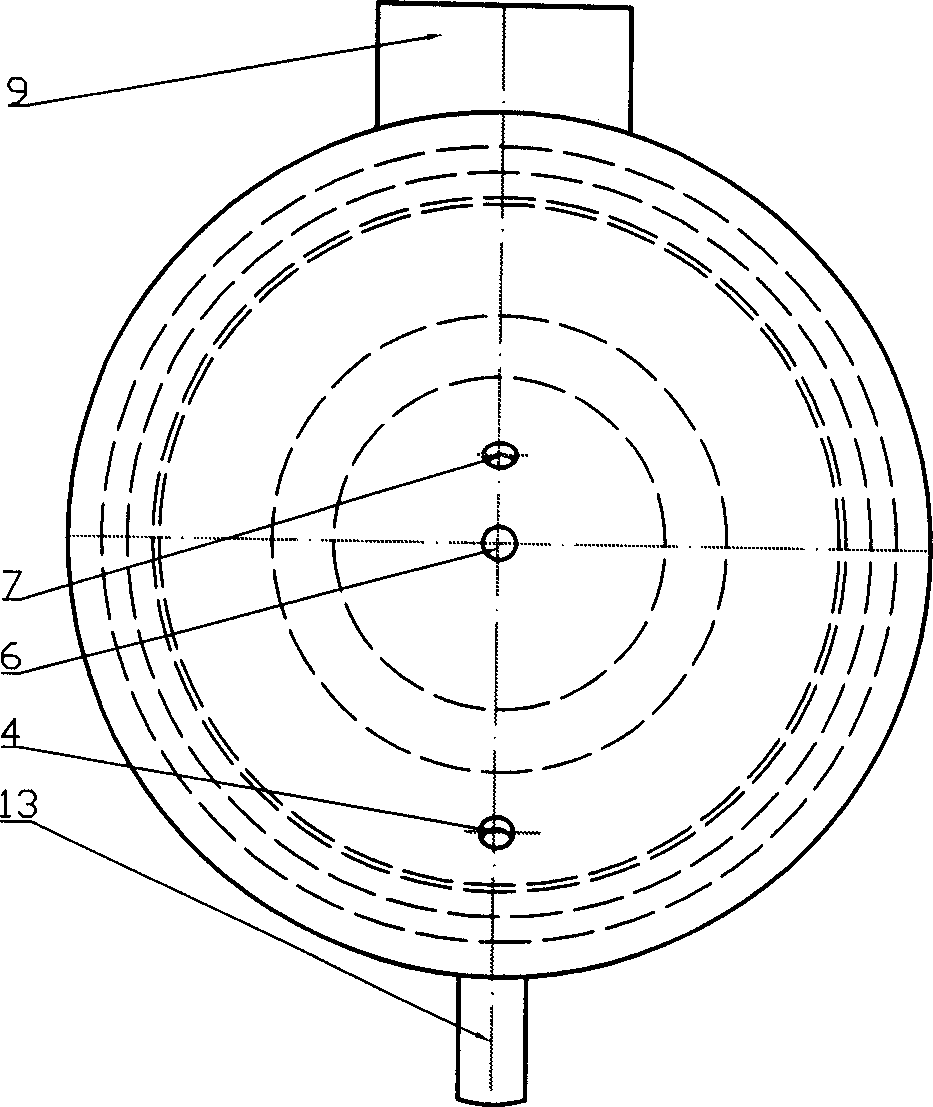

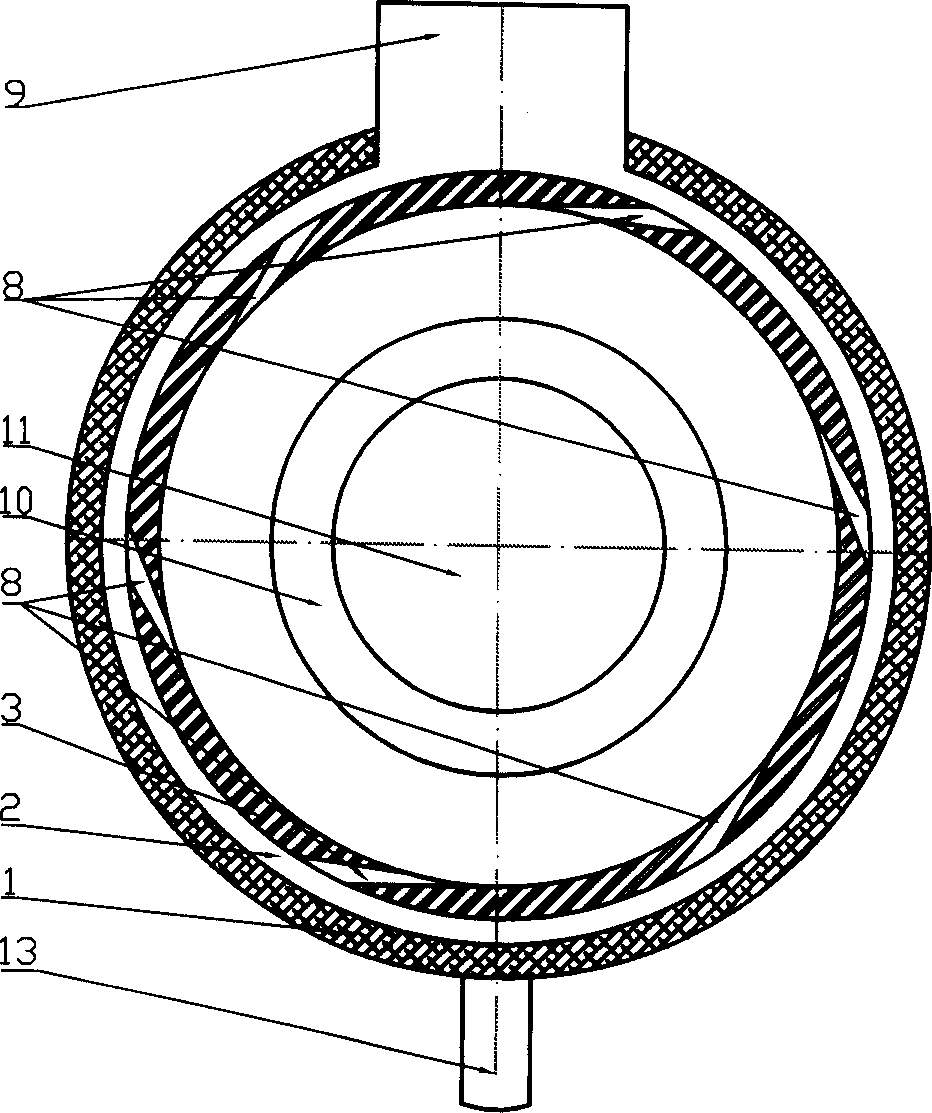

Cyclone burner and its operation method

A cyclone combustion and cyclone technology, which is applied to burners, lighting and heating equipment, etc., can solve the problems of small return flow and unsuitable burning intensity, and achieve the effect of increasing service life, saving heat and reducing failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The usage method of the cyclone burner of the present invention is explained below in the manner of an embodiment.

[0040] Prepare a cyclone burner according to the present invention, use the coal water slurry produced by Beijing Coal Water Slurry Demonstration Factory as fuel, and under the condition of rated load, the amount of burning slurry is 630 kg / hour. The coal water slurry produced by the Beijing Coal Water Slurry Demonstration Plant has a calorific value of 18.5MJ / kg and a theoretical air volume of 4.80Nm 3 / kg coal water slurry, based on 630 kg of coal water slurry per hour, the theoretical air volume is 3024Nm 3 / h. If a conventional burner is used, the air excess coefficient of coal-water slurry combustion is usually 1.2, and the air supply volume is 3628N m under rated load 3 / h. If the cyclone burner of the present invention is used, the air supply coefficient can be 0.6~0.9, such as adopting an air supply coefficient of 0.75, then the air volume is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com