Ceramic substrate and its manufacturing method

A technology of ceramic substrates and manufacturing methods, which is applied in the fields of printed circuit manufacturing, circuit substrate materials, semiconductor/solid-state device manufacturing, etc., can solve the problems of complicated production process and unfavorable mass production, etc., and achieve reduction of plane shrinkage rate and reduction of shrinkage rate , Increase the effect of heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

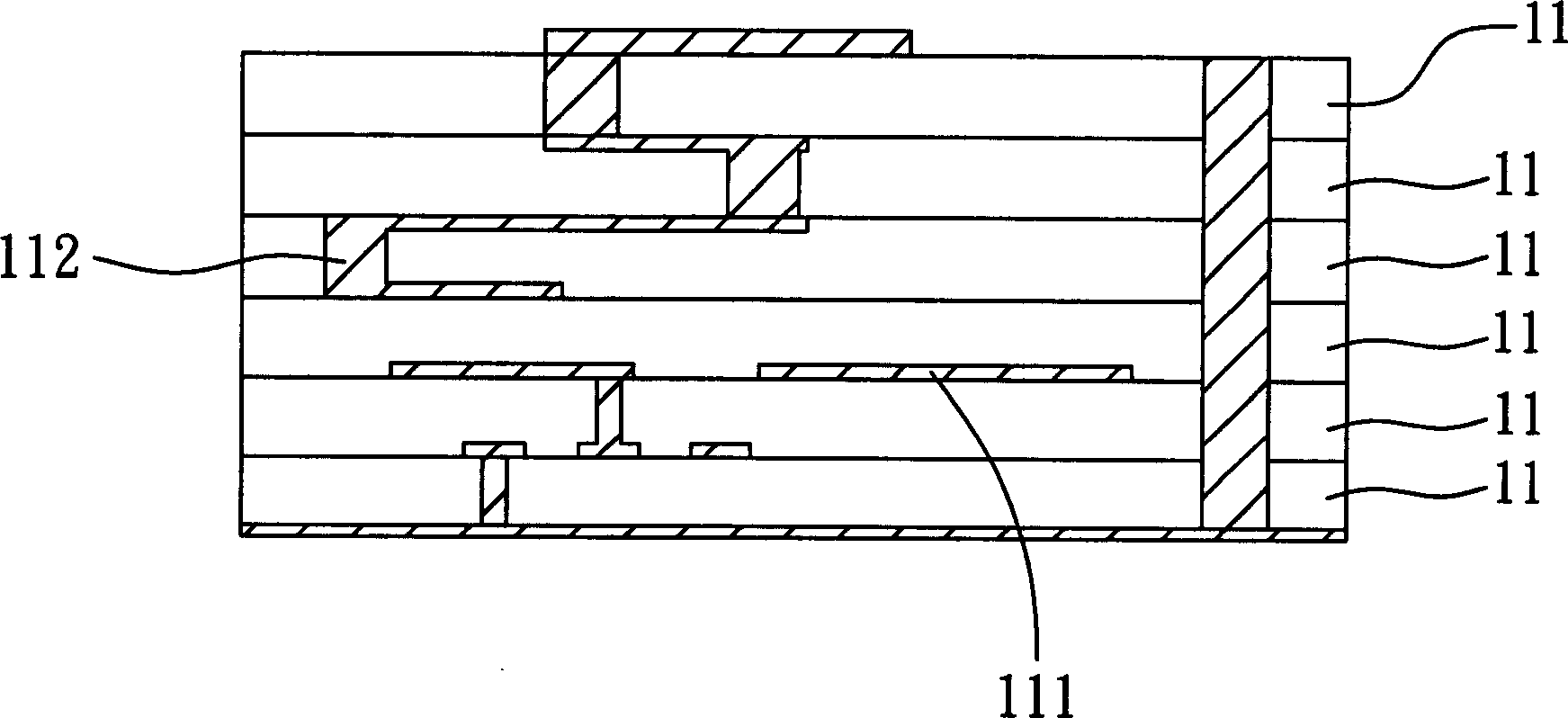

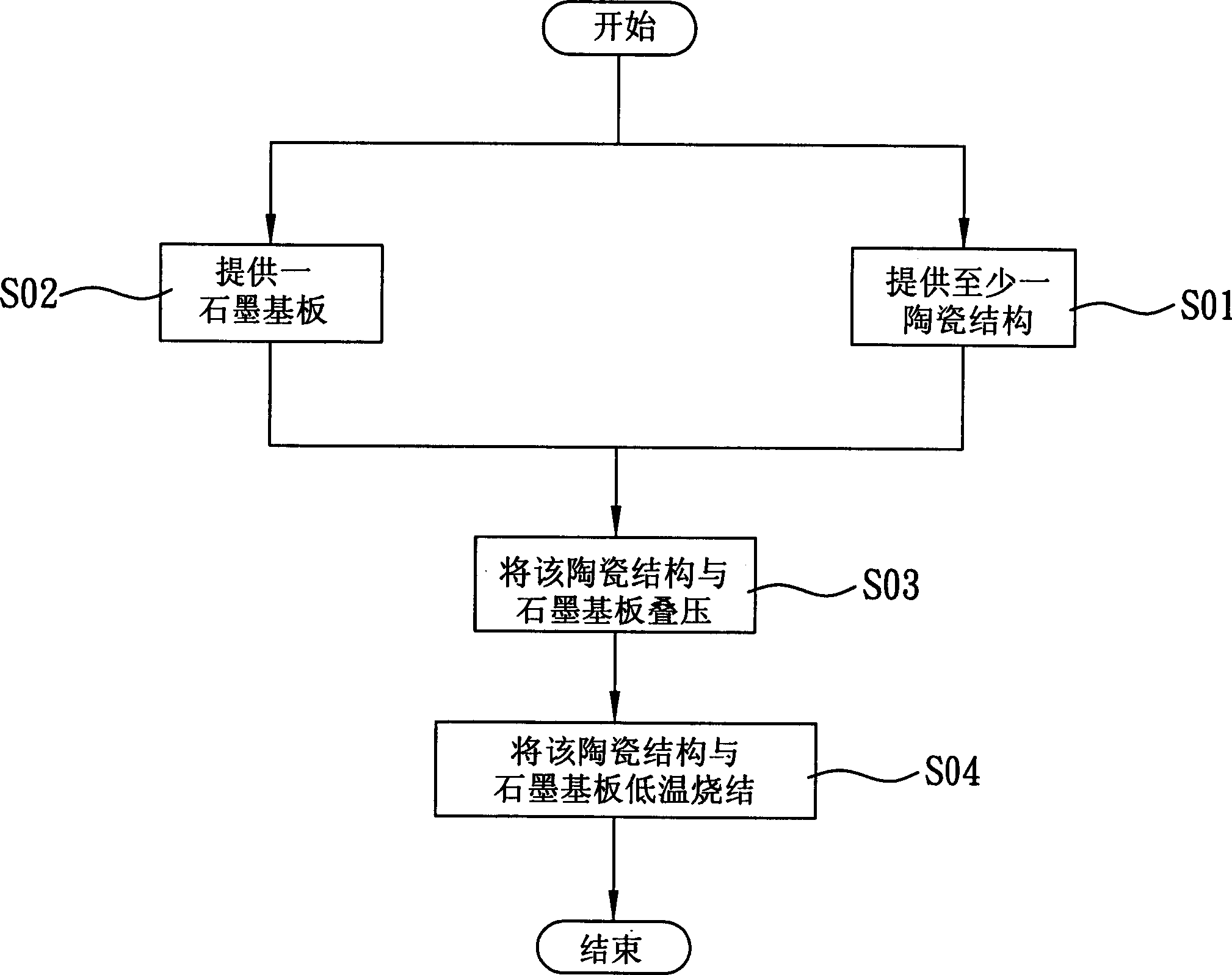

[0027] A ceramic substrate according to a preferred embodiment of the present invention will be described below with reference to related drawings.

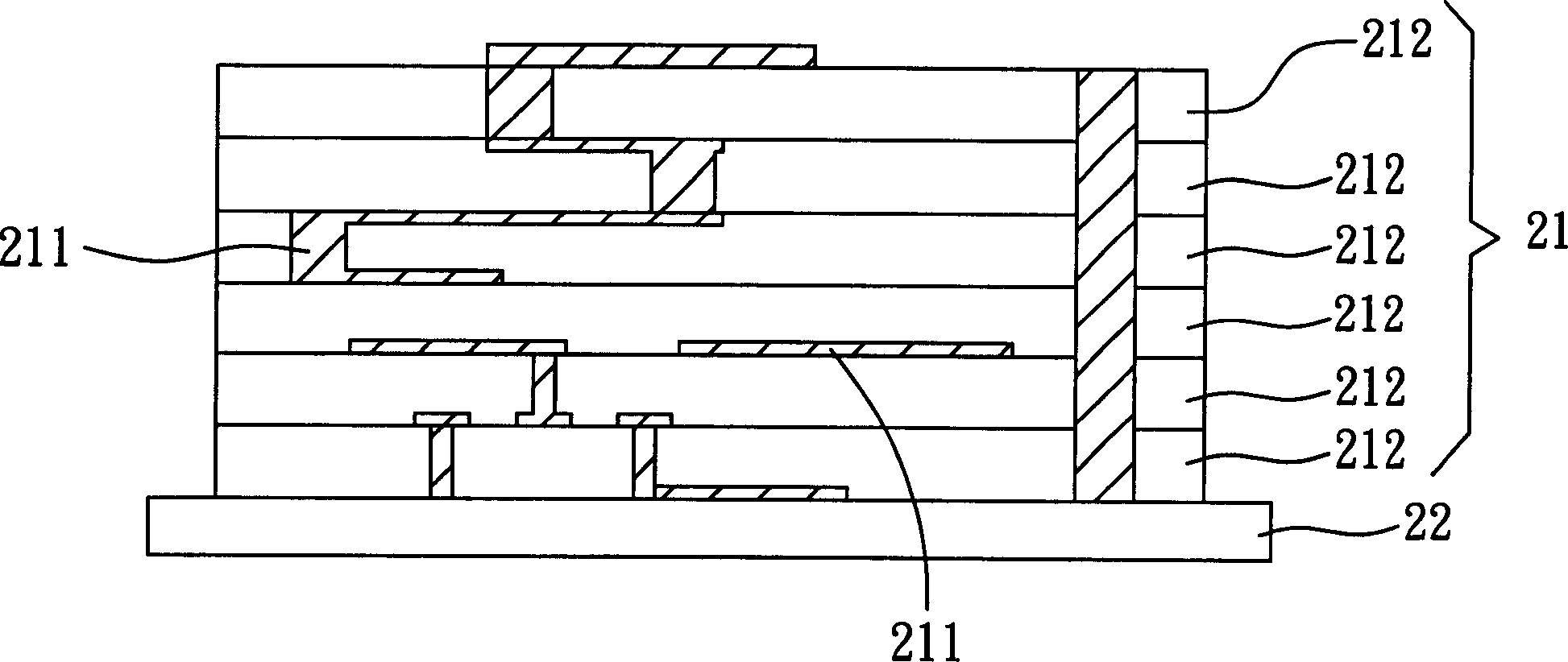

[0028] Please refer to figure 2 Shown is a cross-sectional view of a ceramic substrate in a preferred embodiment of the present invention. The ceramic substrate 2 of the preferred embodiment of the present invention includes at least one ceramic structure 21 and a graphite substrate 22 .

[0029] The ceramic structure 21 can be prepared by mixing different proportions of ceramic powder and glass powder, and appropriate raw materials can be selected according to the required thermal expansion coefficient or other process parameters. Generally speaking, the raw materials of the ceramic structure 21 include alumina, quartz, calcium zirconate (CaZrO 3 ), forsterite (Mg 3 SiO 4 ), silica, andalusite, silicon dioxide, calcium borosilicate glass (Borosilicate Glass), etc., or other raw materials that can be used as ceramics.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com