Vulcanized rubber composition and articles manufactured therefrom

A rubber composition, composition technology, applied in the direction of rubber layered products, applications, layered products, etc., can solve the problems of loss of control of valve opening and closing, loss of pneumatic pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

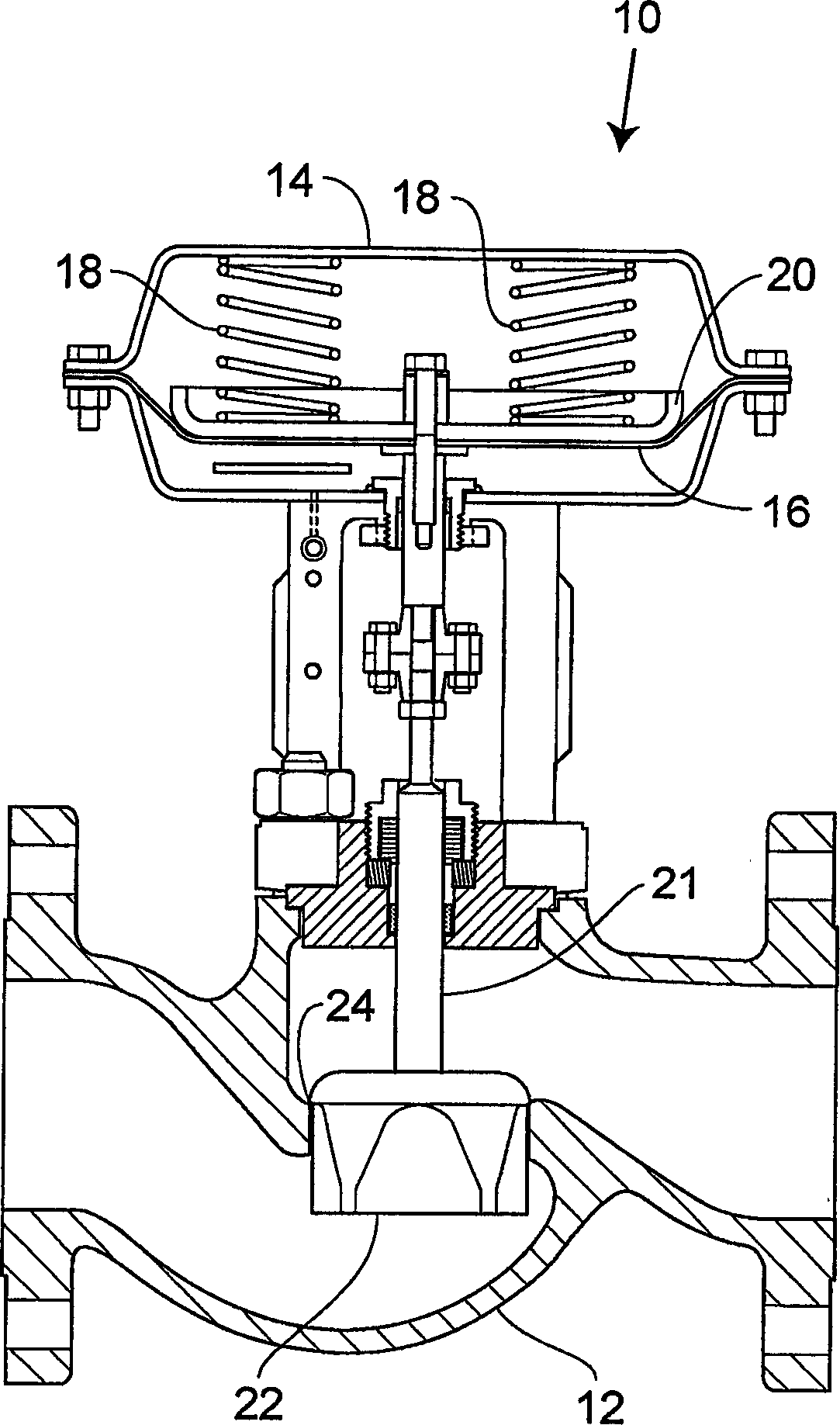

Image

Examples

Embodiment

[0035] 1 Parts per 100 parts of copolymer rubber

[0036] 2 Dibutoxyethoxyethyladipate

[0037] 3 N-isopropyl-N-phenyl-p-phenylenediamine (antioxidant)

[0038] 4 N-Cyclohexylthiophthalimide

[0039] 5 Tetramethylthiuram disulfide

[0040] Hybrid scheme

[0041] Banbury Internal Mixer MB (Banbury MB):

[0042] Add the copolymer rubber and break for 1 minute.

[0043] Blend DSC-18 with Ultrasil VN3 and add to mixer immediately.

[0044] Mix Stearic Acid, Kadox 920C and Santogard PVI with 1 / 2 of N-550 Black and add to mixer.

[0045] Sweep, mix Plasthall 226 with remaining N-550 Black and add to mixer.

[0046] Sweep and add Agerite Resin D, Struktol WB-300, Sunproof Junior and Flexzone3C.

[0047] lower or when the temperature reaches 150°C. The Rhenorgran S-80 was added on the mill immediately after combining the batches.

[0048] Blend for 3 minutes and tablet. Store aged for 24 hours before boosting.

[0049] The mill facilitates:

[0050] Combine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com