Hexafluoropropylene dimmer production method

A technology of hexafluoropropylene dimer and hexafluoropropylene, which is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., and achieves the effects of mild reaction conditions, high conversion rate and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

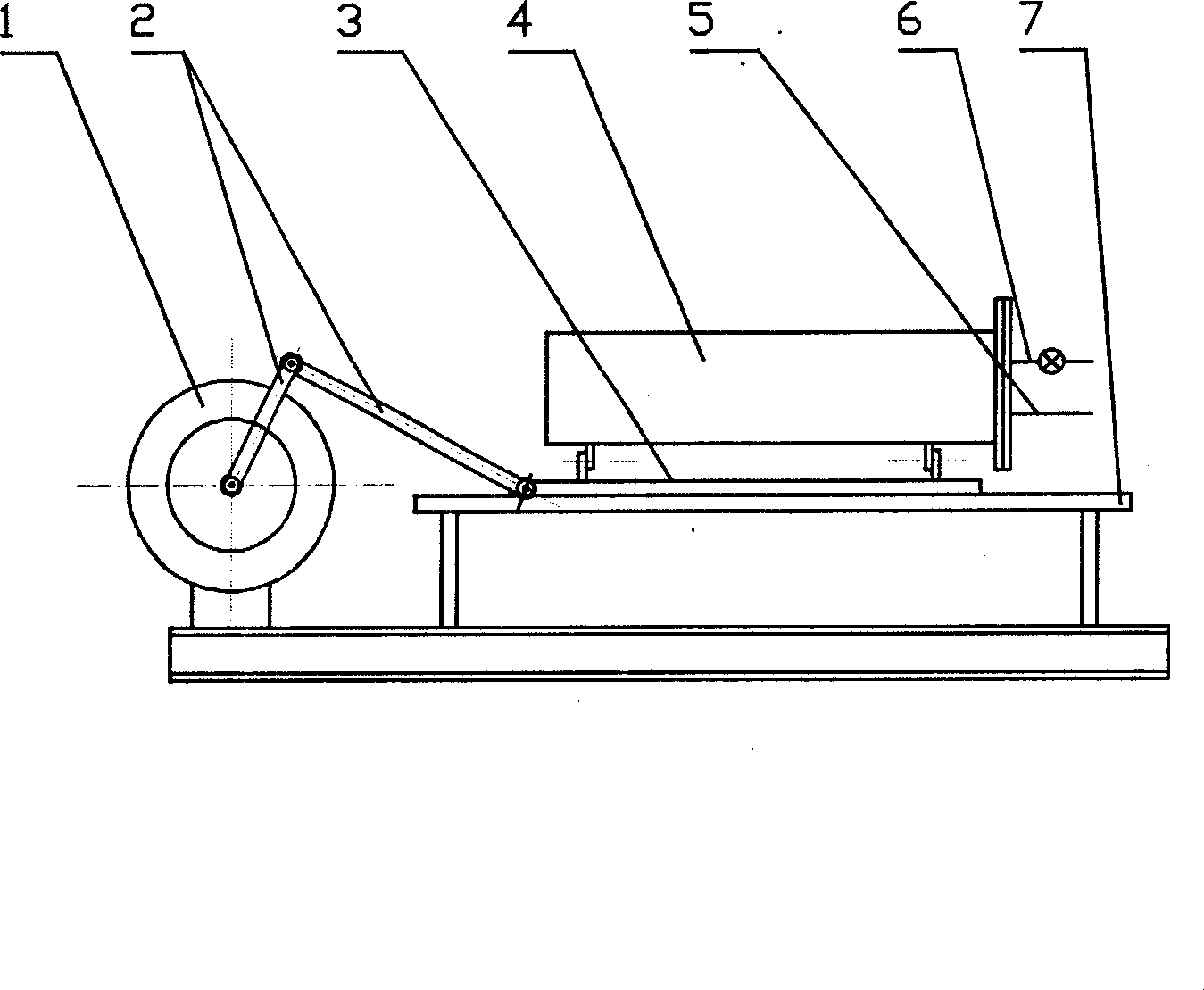

Image

Examples

Embodiment 1

[0015] Embodiment 1, reaction vessel internal diameter 50mm, long 250mm stainless steel, with feed inlet and temperature measuring device, pack 5 grams of potassium thiocyanate, put on the flange cover, vacuumize, inhale 120 gram of acetonitrile, inhale 242 gram Hexafluoropropylene, close the valve on the feed inlet, and be fixed on the slide plate (3) of the crank connecting rod swing device. Start the swinging device at room temperature, the swinging frequency is 2 times per second, and the swinging distance is 100mm, react for 7 hours, and let it stand overnight to obtain 210 grams of the bottom crude product and 132 grams of the upper acetonitrile layer. Distill the crude product in a three-necked flask to collect fractions at 30-40°C to obtain 183 grams of the product. Analyzed by gas chromatography, it contains 97.07% of hexafluoropropylene dimer, and the yield is 73.40%. The acetonitrile layer was distilled in a three-necked flask to obtain 115 grams of acetonitrile, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com