Vacuum air-discharging system

A vacuum exhaust and vacuum pump technology, which is applied to electrical components, circuits, liquid fuel engines, etc., can solve problems such as vacuum pump stop, reaction by-products mixed in, and impact on pump limit pressure, etc., to achieve the effect of prolonging life and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

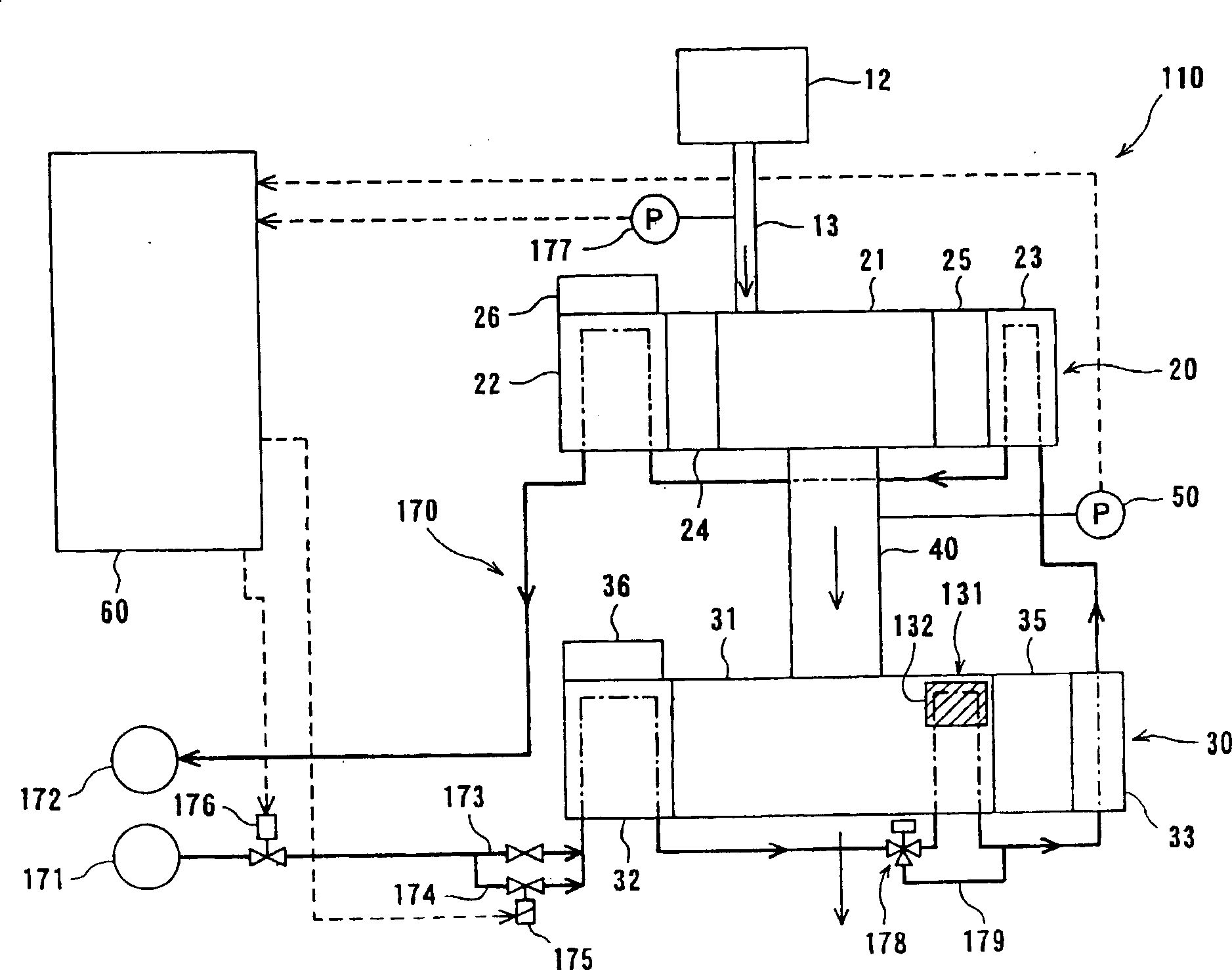

[0026] Refer below Figure 1 to Figure 8 Embodiments of the vacuum exhaust system of the present invention will be described in detail. In addition, in Figure 1 to Figure 8 Among them, the same reference numerals are assigned to the same or equivalent constituent elements to omit repeated explanations.

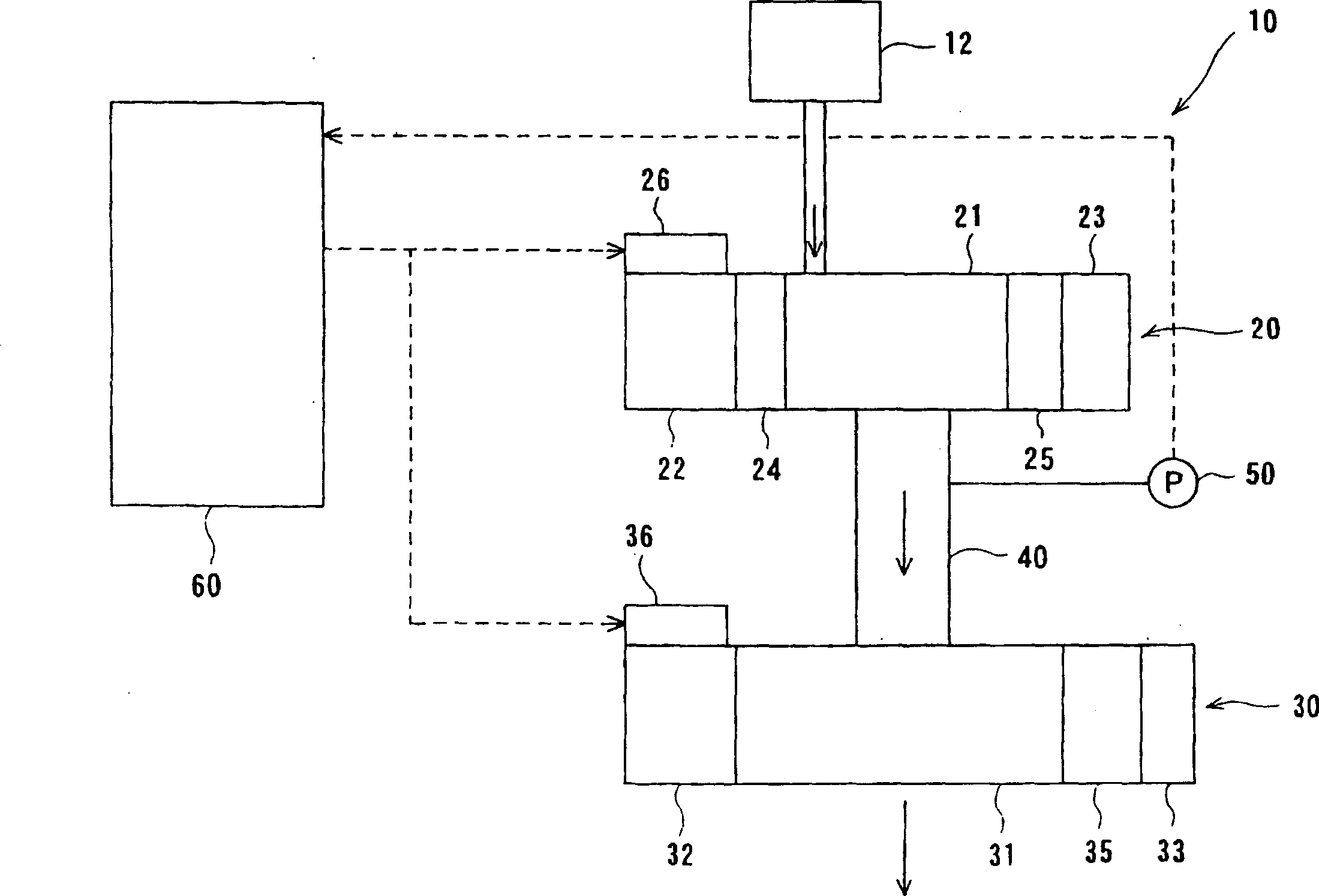

[0027] figure 1 It is a schematic diagram showing the vacuum evacuation system 10 according to the first embodiment of the present invention. Such as figure 1 As shown, the vacuum exhaust system 10 is a system for exhausting the vacuum chamber 12 used in the semiconductor manufacturing process or the liquid crystal manufacturing process to a vacuum, including: 2 vacuum pumps 20, 30; connecting the front vacuum pump 20 and the rear stage The connecting pipe 40 of the vacuum pump 30 ; the pressure sensor 50 for detecting the internal pressure of the connecting pipe 40 ; and the control unit 60 for controlling the vacuum pumps 20 and 30 . The pressure sensor 50 detects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com