Test equipment of semiconductor devices

An inspection device and semiconductor technology, applied in the direction of single semiconductor device testing, semiconductor/solid-state device testing/measurement, measuring devices, etc., can solve the problems of rising prices and increasing the proportion of test costs, and achieve the increase of transition reaction speed and test The effect of shortening the time and reducing the influence of motion noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, preferred forms for carrying out the present invention will be described more specifically with reference to the accompanying drawings. Here, in the drawings, the same components are assigned the same reference numerals, and redundant descriptions are omitted. Furthermore, since the description herein is of a preferred form of carrying out the invention, the invention is not limited to this form.

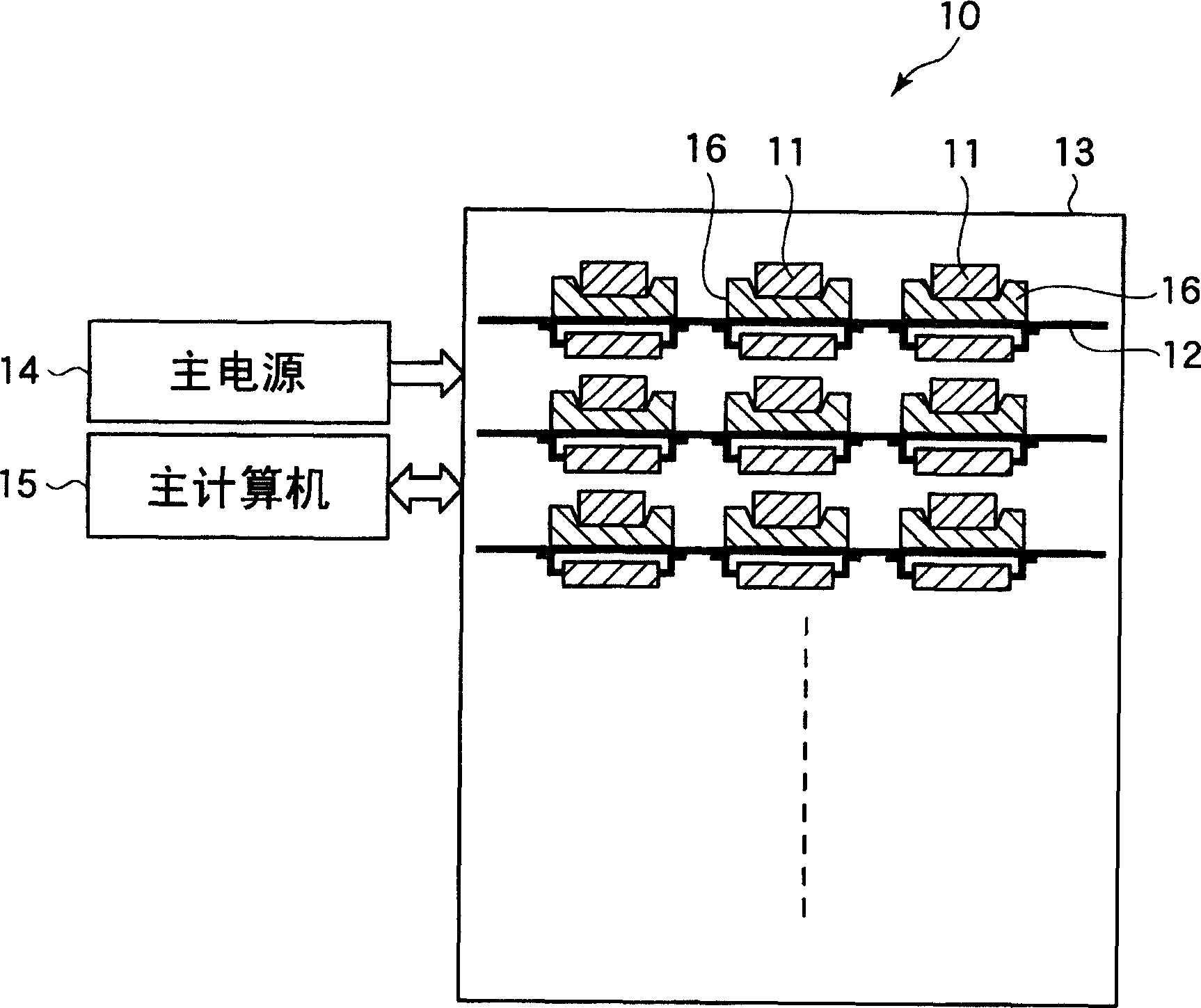

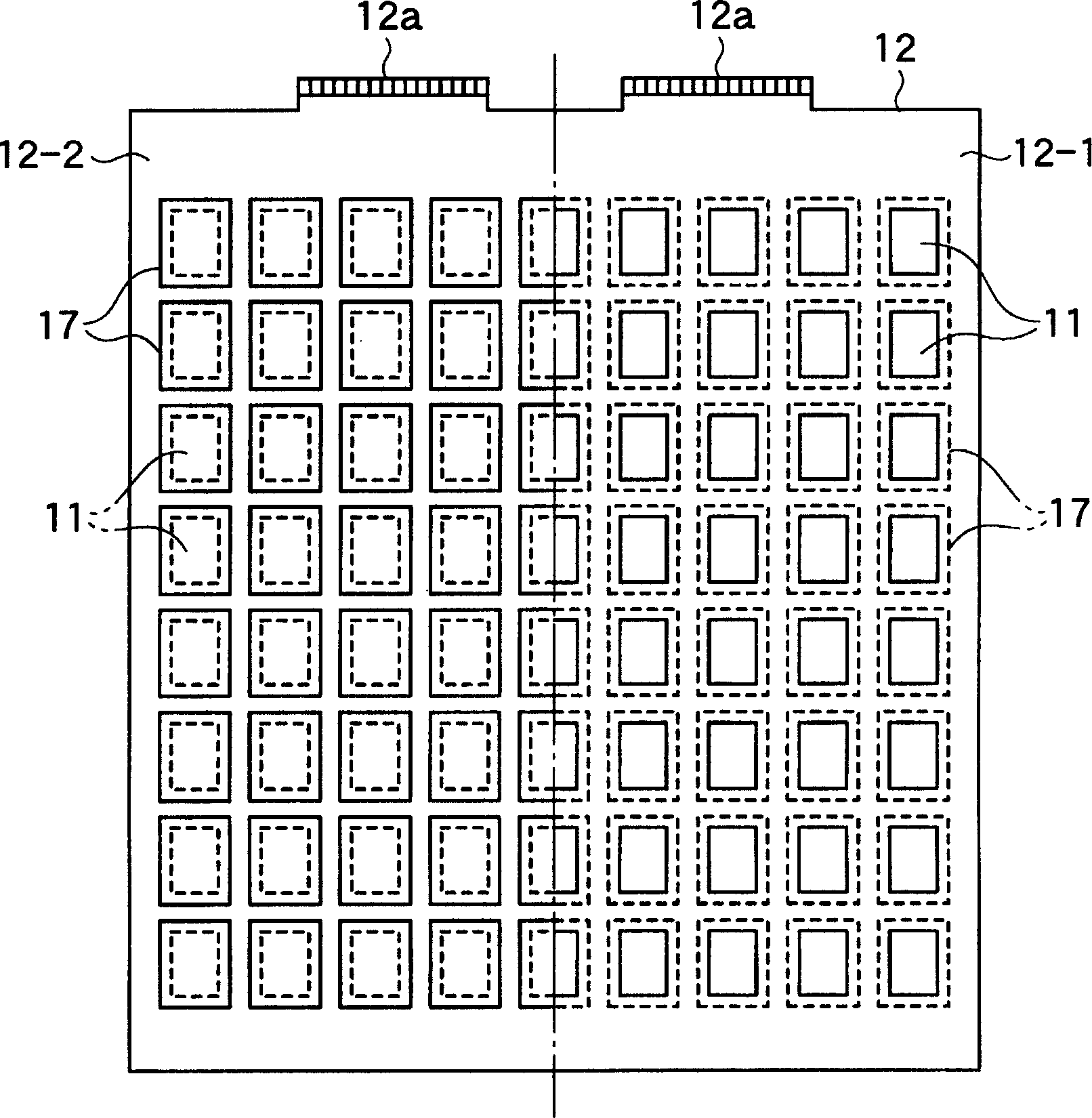

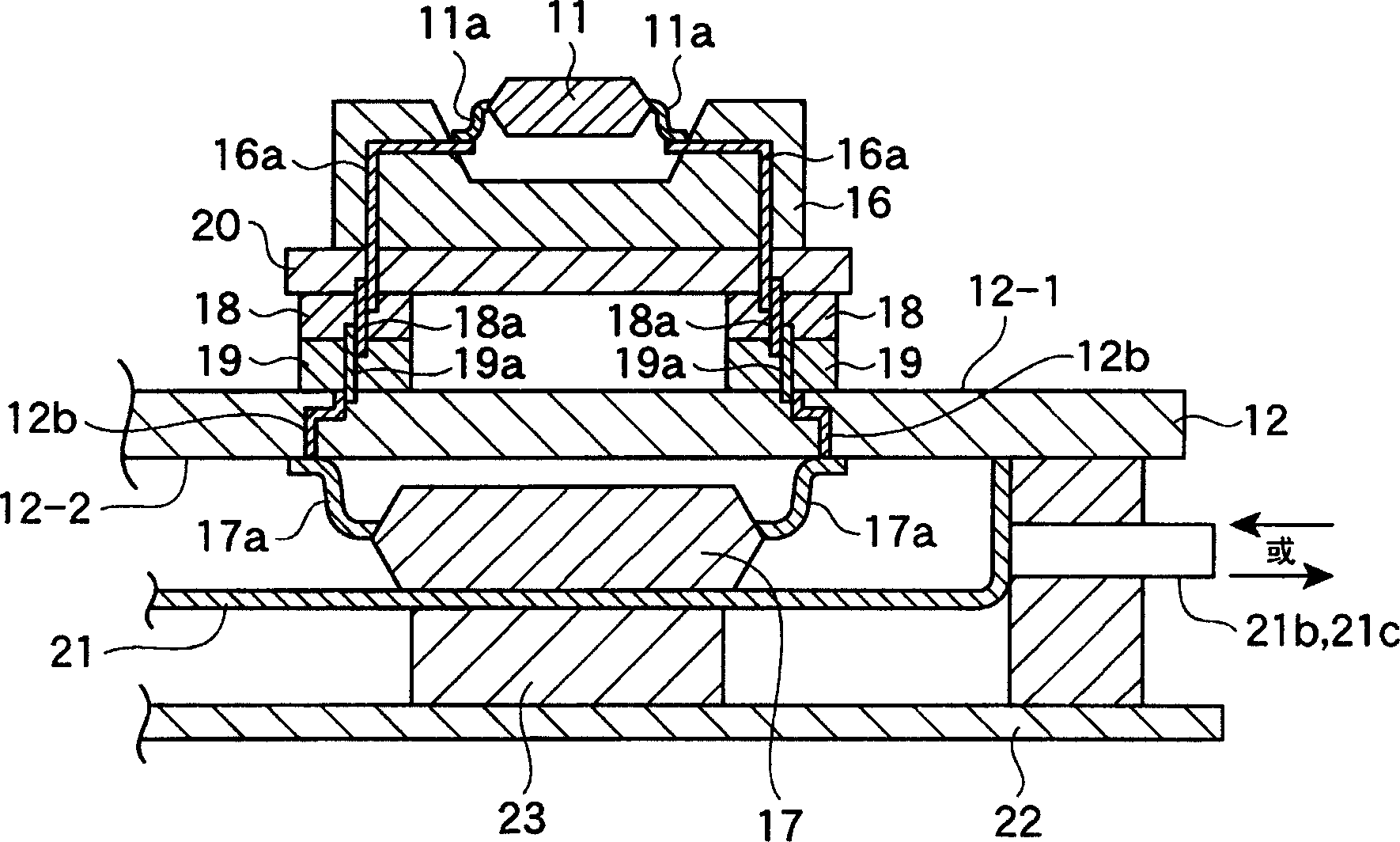

[0050] figure 1 is a conceptual diagram showing an inspection device for a semiconductor device according to an embodiment of the present invention, figure 2 for expressing in figure 1 An explanatory diagram of a test board accommodated in a cavity in an inspection device for a semiconductor device, image 3 for figure 2 A cross-sectional view of the test plate, Figure 4 Fig. 5 is a block diagram showing the functional structure of the device testing mechanism mounted on the test board, which is a perspective view showing the cooling mechanism mounted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com