Multi-section flat type photo-bioreactor

A photobioreactor, reactor technology, applied in photobioreactor, bioreactor/fermenter for specific purposes, bioreactor/fermenter combination, etc., can solve the problem of ineffective oxygen analysis, algal culture Efficiency effects, restrictions on the application of built-in light sources, etc., to achieve the effects of high light energy utilization efficiency, easy processing and promotion, and promotion of liquid circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

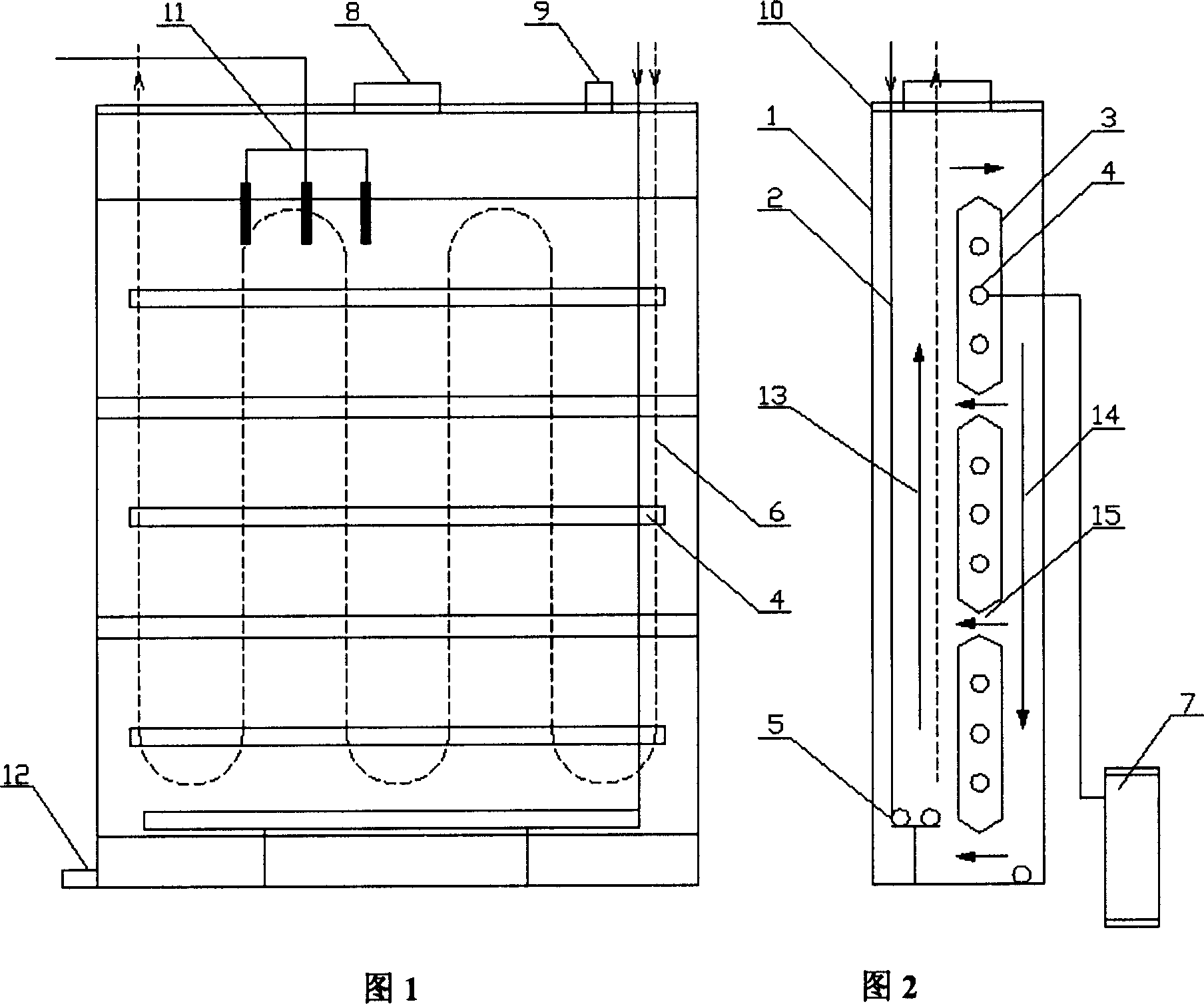

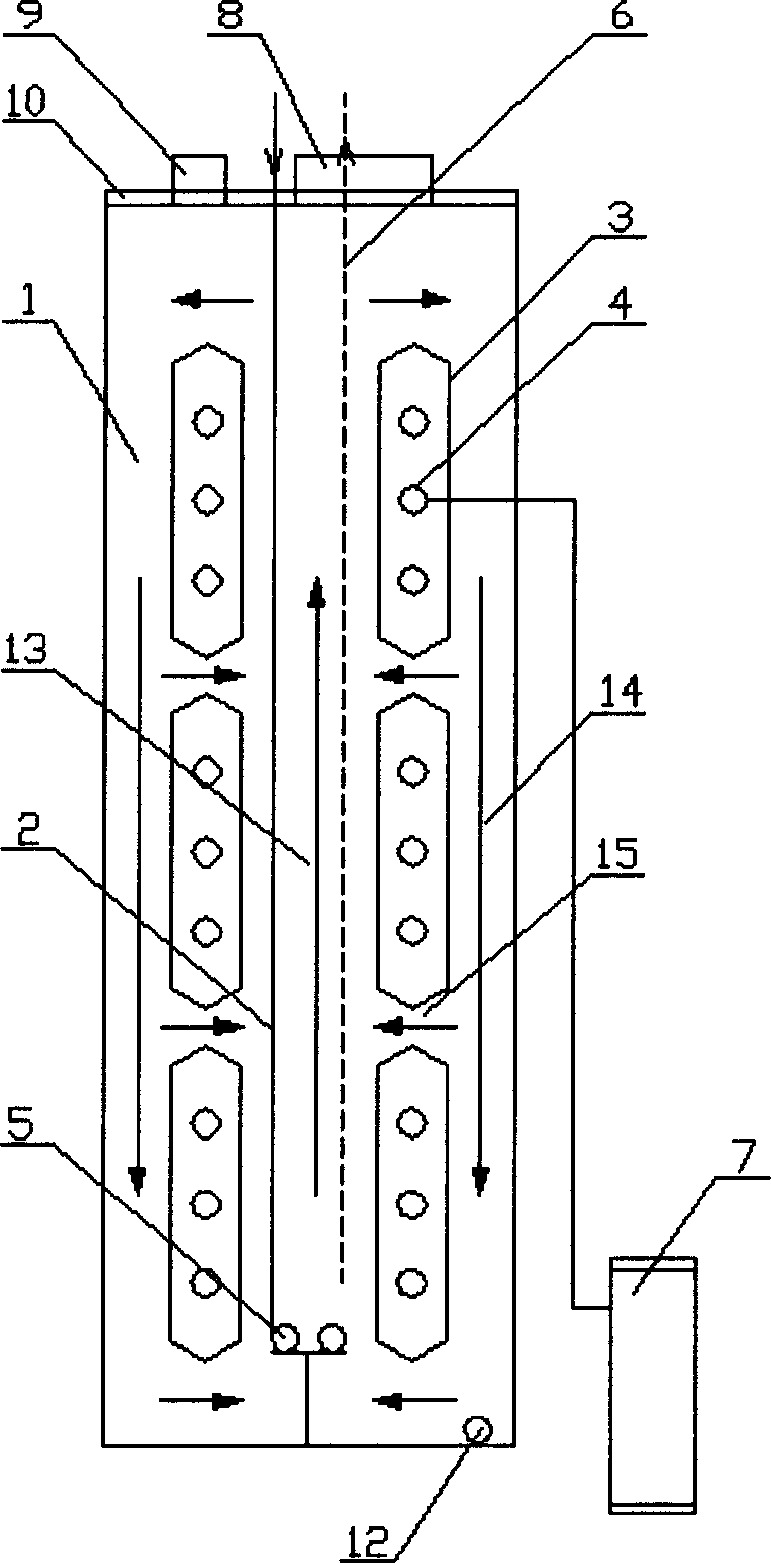

Method used

Image

Examples

Embodiment 1

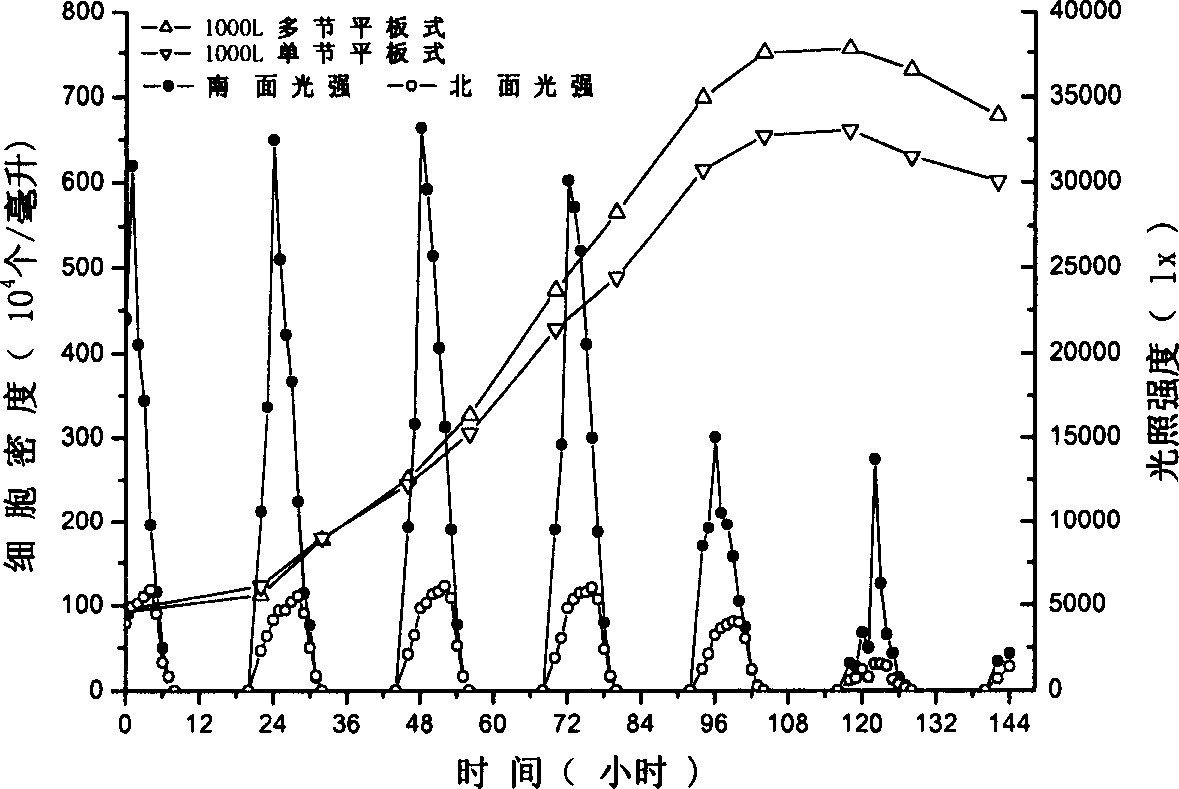

[0085] Embodiment 1: Adopt the comparison of the present invention and single-section plate photobioreactor culture efficiency

[0086] Under natural light, the cultivation efficiency of the 1000L multi-section-air-lift type-internal light source-flat-panel photobioreactor of the present invention and the 1000L single-section air-lift type flat-panel photobioreactor were compared. The medium used is: NaNO 3 : 90mg / L, KH 2 PO 4 : 5mg / L, FeC 6 h 5 o 7 ·5H 2 O: 0.5mg / L; the culture temperature is 25-30℃; the actual liquid volume of 1000L multi-section plate reactor and 1000L single-section plate reactor is about 800L, and the gas-liquid ratio is 0.1vvm; the algae species used for cultivation are Isoflagellates 3011 (commercially available).

[0087] The seawater used in the test was preliminarily treated by sedimentation, pressurized sand filtration, etc., and then sterilized by oxidation. Before use, add about 1L of commercially available bleach solution (with an availabl...

Embodiment 2

[0089] Embodiment 2: adopt the high-density cultivation of the present invention to widely use Phaeodactylum tricornutum in seawater seedling cultivation

[0090] The medium used is: NaNO 3 : 90mg / L, KH 2 PO 4 : 5mg / L, FeC 6 h 5 o 7 ·5H 2 O: 0.5mg / L; the culture temperature is 20-25°C; the actual liquid volume of a 1000L plate reactor is about 800L. The seawater treatment method used in the test is the same as in Example 1.

[0091] Under the situation of natural light and increasing artificial light source respectively, compared the cultivation efficiency of 1000L plate type reactor of the present invention and 300L cylindrical type reactor, 300L cylindrical type reactor is a kind of standing bag with support on the periphery, is the current domestic A more advanced culture system for industrial bait microalgae culture. During the cultivation process, the average natural light intensity on the surface of various reactors is: about 8000lx on the sunny side and about 35...

Embodiment 3

[0096] Embodiment 3: Isochrysis globosa 3011 widely used in seawater seedling cultivation by high-density culture of the present invention

[0097] The medium used is: NaNO 3 : 90mg / L, KH 2 PO 4 : 5mg / L, FeC 6 h 5 o 7 ·5H 2 O: 0.5mg / L; the culture temperature is 24-32°C; the actual liquid volume of a 1000L plate reactor is about 800L. The seawater treatment method used in the test is the same as in Example 1.

[0098] The cultivation efficiency of the 1000L multi-section-airlift-inner light source-flat plate photobioreactor and the 300L cylindrical type reactor of the present invention were compared under the conditions of natural light and artificial light source respectively. In the artificial light source group, when the daytime (8:00-18:00) sunlight intensity is less than 8000lx, artificial light source is added, and the lamp tube-liquid volume ratio is 6 lamp tubes / 300L, of which 1000L flat plate reactor artificial light source The form is an internal light source...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com