Thermally-grown Cr2O3 or Al2O3 film type M-Cr-Al nano composite coating and method for preparing same and application thereof

A nano-composite and composite coating technology, applied in coatings, electrolytic coatings, etc., to achieve the effect of improving high temperature and oxidation resistance, low cost, and improving coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

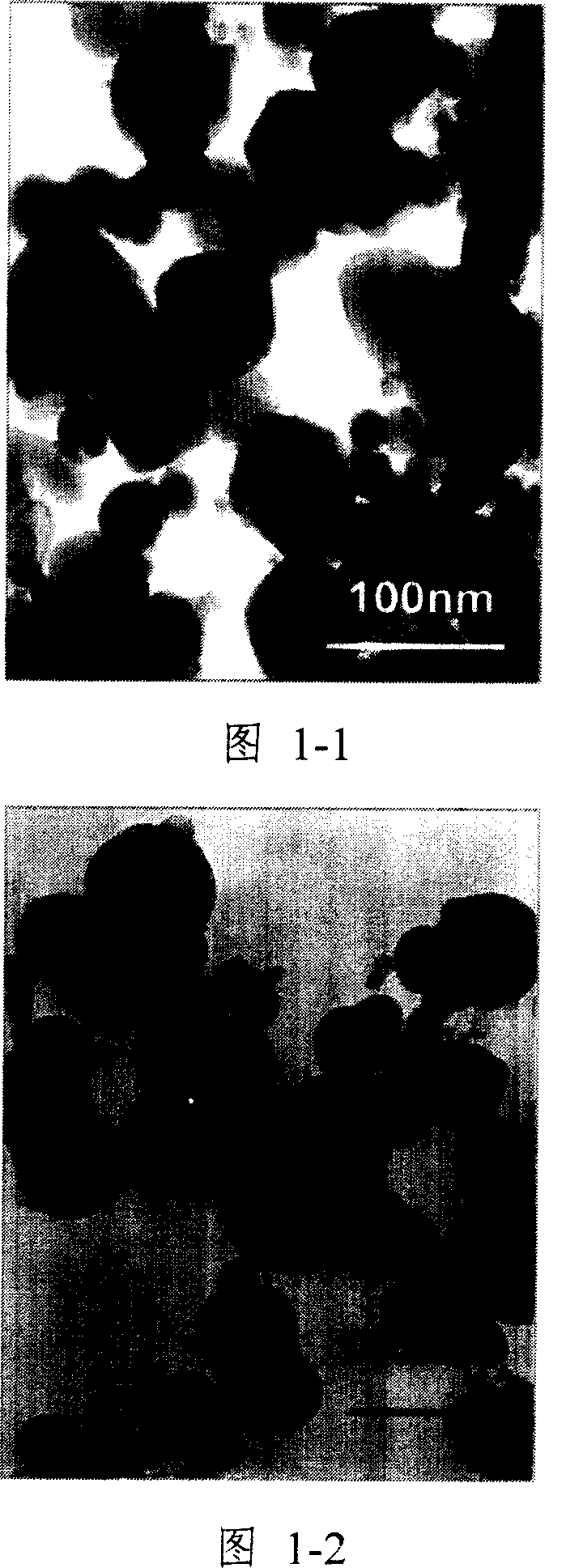

[0036] This embodiment introduces the preparation and performance of Ni-Cr-Al nanocomposite coating, and its preparation method is to adopt conventional co-electrodeposition (composite electroplating) technology to prepare Ni-Cr-Al nanocomposite coating; Plating solution is to use sodium citrate as The sulfate system of the complexing agent, Cr powder and Al powder are all nano-sized. Present embodiment will be described in detail with the preparation of Ni-Cr-Al nanocomposite coating and result example, and Fig. 1-1, 1-2 are the transmission electron microscope (TEM) morphology of nano-Cr powder and Al powder used in this experiment, As can be seen from the figure, the average particle sizes of the nano-Cr powder and Al powder used are 60nm and 85nm respectively (the particle size ranges of the nano-Cr powder and Al powder in the present invention are respectively 14-89nm, 16-100nm).

[0037] The process of preparing Ni-Cr-Al nanocomposite coating in this embodiment is as fol...

Embodiment 2

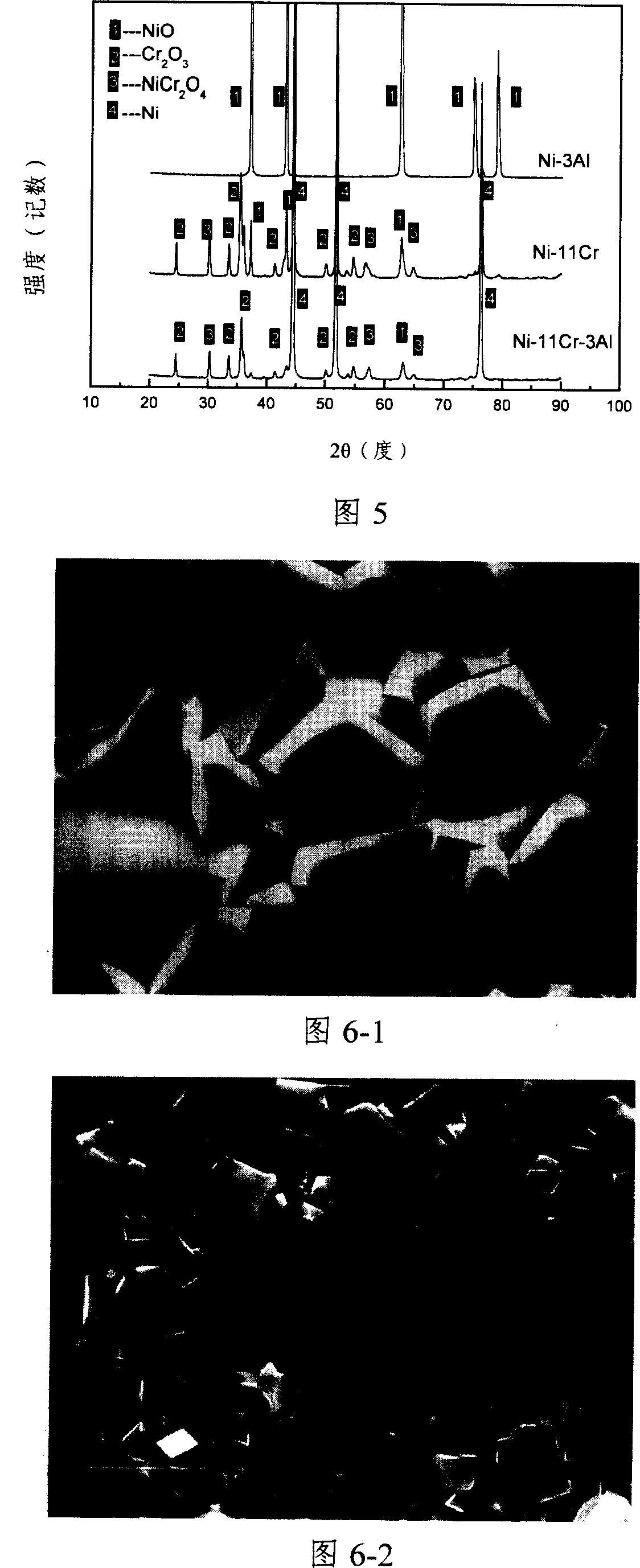

[0047] This embodiment provides thermally grown Cr 2 o 3 Properties and morphology of film-type Ni-Cr-Al nanocomposite coatings and Ni-Cr and Ni-Al nanocomposite coatings oxidized in air at 900°C for 24h (preparation method is the same as above). Specifically, Ni-11Cr-3Al, Ni-11Cr and Ni-3Al nanocomposite coatings are taken as examples.

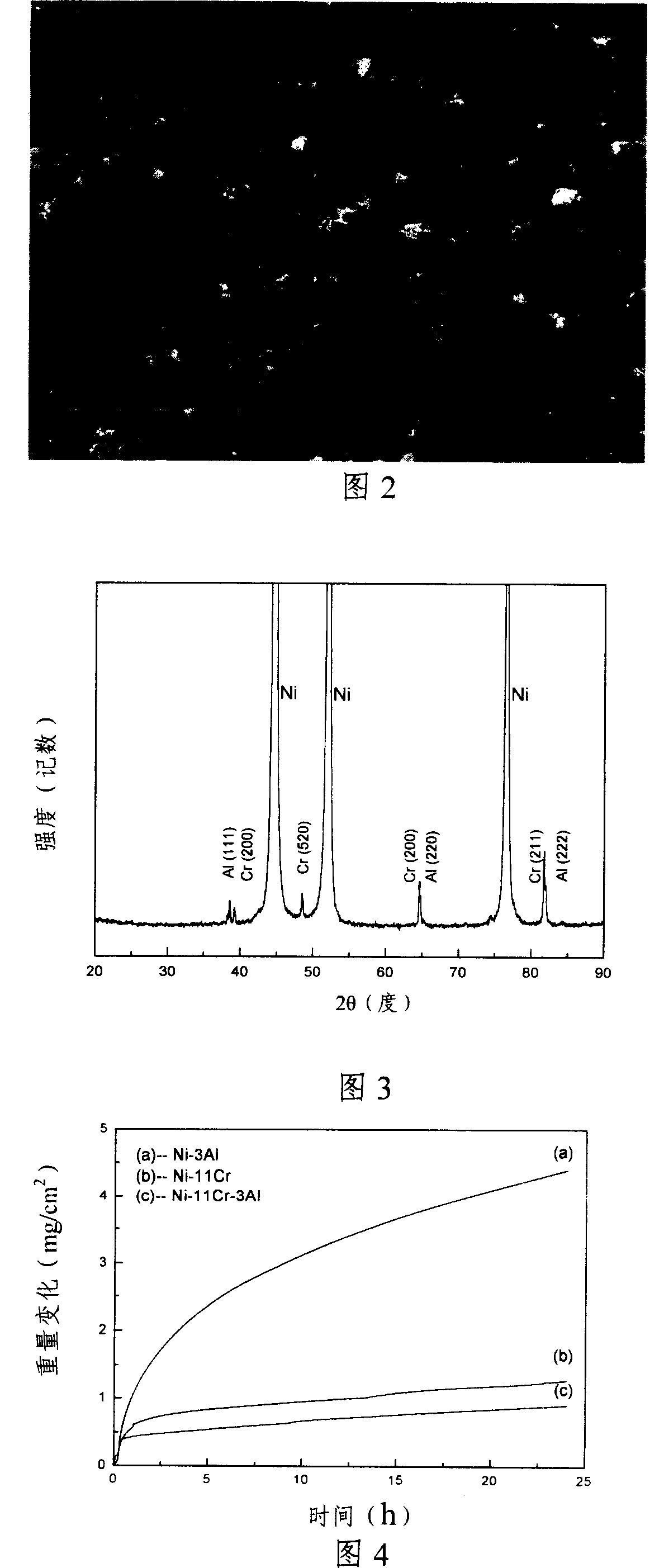

[0048] The high-temperature oxidation experiment uses a TGA instrument of the type TherMax700 produced by Thermo Cahn Company. The heating rate is 50°C / min, and the temperature is kept at 900°C for 24 hours, and then cooled with the furnace. Figure 4 is the thermogravimetric analysis (TGA) kinetic curves of Ni-11Cr-3Al, Ni-11Cr and Ni-3Al nanocomposite coatings oxidized in air at 900°C for 24h. It can be seen from the figure that the oxidation weight gain of the Ni-11Cr-3Al nanocomposite coating is the lowest. The calculated oxidation parabolic constants of the three samples are 7.8×10 -12 , 1.4×10 -11 , 3.4×10 -9 g 2 / cm 4 ·s. Compa...

Embodiment 3

[0050] This example provides thermally grown Al 2 o 3 Properties and morphology of film-type Ni-Cr-Al nanocomposite coatings after oxidation in air at 900°C and 1000°C for 24h. Specifically, take Ni-5Cr-9Al nanocomposite coating as an example (the preparation method and high temperature oxidation test method are the same as above).

[0051] Fig. 8 is a graph comparing thermogravimetric analysis (TGA) curves of Ni-5Cr-9Al nanocomposite coatings oxidized in air at 900°C and 1000°C for 24 hours. Although the oxidation kinetics of the coating at 1000 °C is significantly higher than that at 900 °C, it can be seen from the comparison of the XRD analysis results of the above coating at 900 °C and 1000 °C in air in Figure 9 that Ni- The 5Cr-9Al nanocomposite coating has produced Al at the above two temperatures 2 o 3 . The above results can also be confirmed from the surface morphology (Figure 10-1, 10-2) and cross-sectional morphology (11-1, 11-2) of the corresponding oxide laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com