Method for removing mercury for flue gas by using sulfo-halogen compound-supported modified adsorbent

A compound and adsorbent technology, applied in the field of flue gas mercury removal, can solve the problems of reducing the amount of adsorbent used, secondary pollution, etc., and achieve the effect of reducing secondary pollution of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

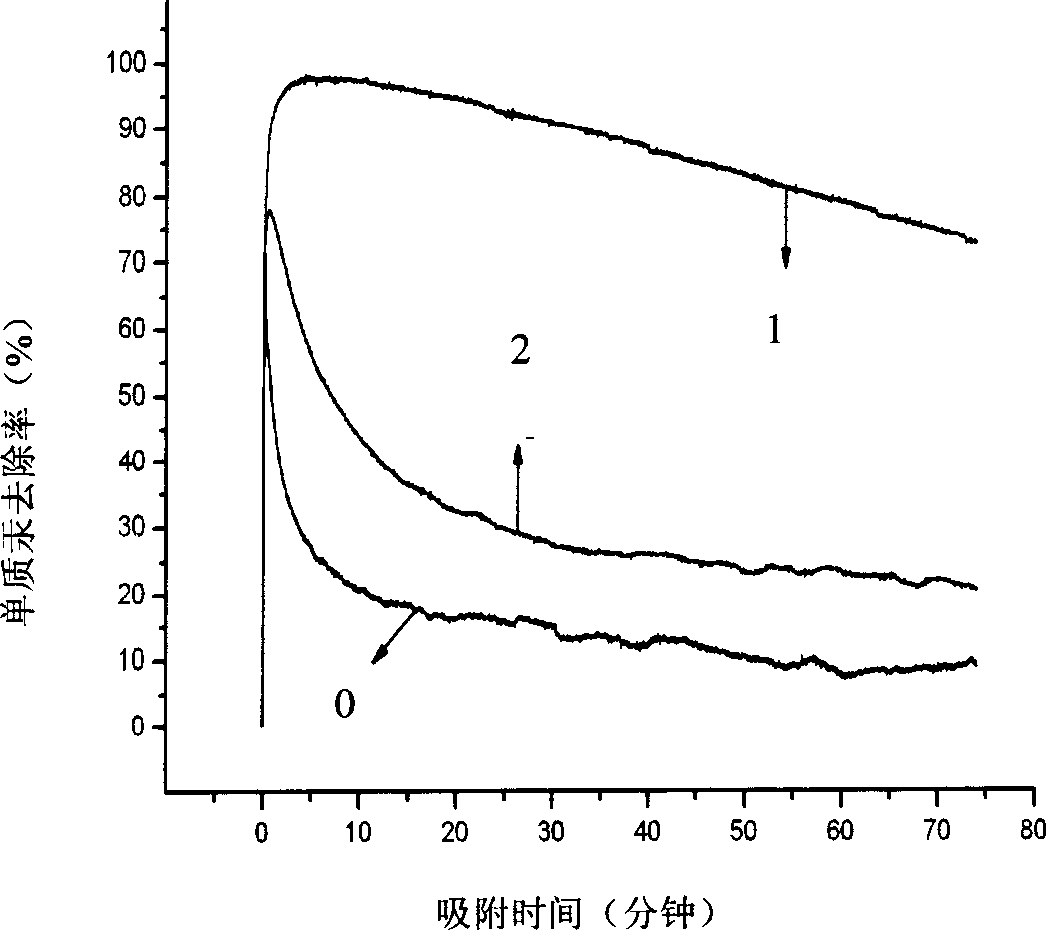

[0028] Embodiment 1 (activated carbon supported disulfur dichloride)

[0029] Loading method: take 5 mL of disulfur dichloride (analytical purity, >98%), and put it into a 50 mL glass vaporizer. Immerse 2 / 3 of the volume of the vaporizer in an oil bath, and use the oil bath to control the temperature of the vaporizer. In addition, 100 g of activated carbon with a particle size of 100-120 mesh was weighed, and it was placed in a three-necked flask with a volume of 500 mL as an adsorption bottle. One port of the flask is used to install the stirrer, and the other two ports are respectively used as the inlet and outlet of sulfur dichloride vapor. Connect the gas outlet of the vaporizer bottle to the gas inlet of the adsorption bottle.

[0030] Turn on the heating power of the oil bath to keep the temperature of the vaporizing bottle at about 120°C, disulfur dichloride is continuously evaporated and vaporized, and its vapor is introduced into the adsorption bottle. The stirrer ...

Embodiment 2

[0035] Using a loading method similar to that of Example 1, disulfur dibromide was vaporized at 200° C., and the activated carbon powder was fumigated and loaded with its steam, so that the loading of dibromide on the activated carbon was about 0.5%. 0.02g of activated carbon was weighed as an adsorbent, and the main experimental conditions were the same as in Example 1 for the adsorption experiment of mercury-containing gas.

[0036] It was found that activated carbon loaded with disulfur dibromide had a better adsorption effect on elemental mercury. When the adsorption time was 100 minutes, the removal rate of elemental mercury was still above 92%.

Embodiment 3

[0038] Using a loading method similar to that of Example 1, sulfur and disulfur dibromide were vaporized at a temperature of 200° C., and loaded on different coal-fired fly ash, respectively, with a loading amount of about 0.5%. Weigh 0.1 g of the modified adsorbent respectively, so that the thickness of the adsorption layer is about 2 mm. The adsorption experiment conditions of mercury-containing gas are also the same as in Example 1.

[0039] It was found that the fly ash loaded with disulfide dibromide had a better adsorption effect on elemental mercury. When the adsorption time was 30 minutes, the removal rate of elemental mercury was still above 85%. And under the same situation, when using the fly ash loaded with sulfur or the fly ash not loaded with any substance, the adsorption effect on elemental mercury is very poor. When the adsorption time is 5 minutes, the removal rate of elemental mercury drops below 20%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com