Method for deferrization and whitening of palygorskite by using sodium oxalate and hydrochloric acid

A palygorskite and sodium oxalate technology, applied in the material field of the chemical industry, can solve problems such as limited improvement of whiteness, difficult conditions to control, complicated operation, etc., and achieve the effect of simple operation, easy control of conditions, and good bleaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add palygorskite powder into a beaker, add a certain amount of water and stir evenly to make a 5% original slurry, and let it stand for 2 hours to precipitate large particles of impurities. Take out 70% by volume of the upper layer slurry by the upper layer discharge method, and discard the bottom sediment. Add sodium oxalate to the upper slurry to make the concentration of sodium oxalate 2% by weight; add hydrochloric acid dropwise to make the pH of the slurry ≤ 3, stir evenly, and ultrasonicate for 30 minutes in an ultrasonic instrument to fully refine the palygorskite particles. Then heat and stir at 80° C. for 2 hours, so that the iron ions in the palygorskite are fully dissolved, and complexed with oxalate ions and dissolved in the liquid phase. Stop heating, carry out suction filtration while hot, the filtrate is yellow. Wash with water several times until the filtrate is neutral. The target product is obtained by drying and grinding according to conventional me...

Embodiment 2-8

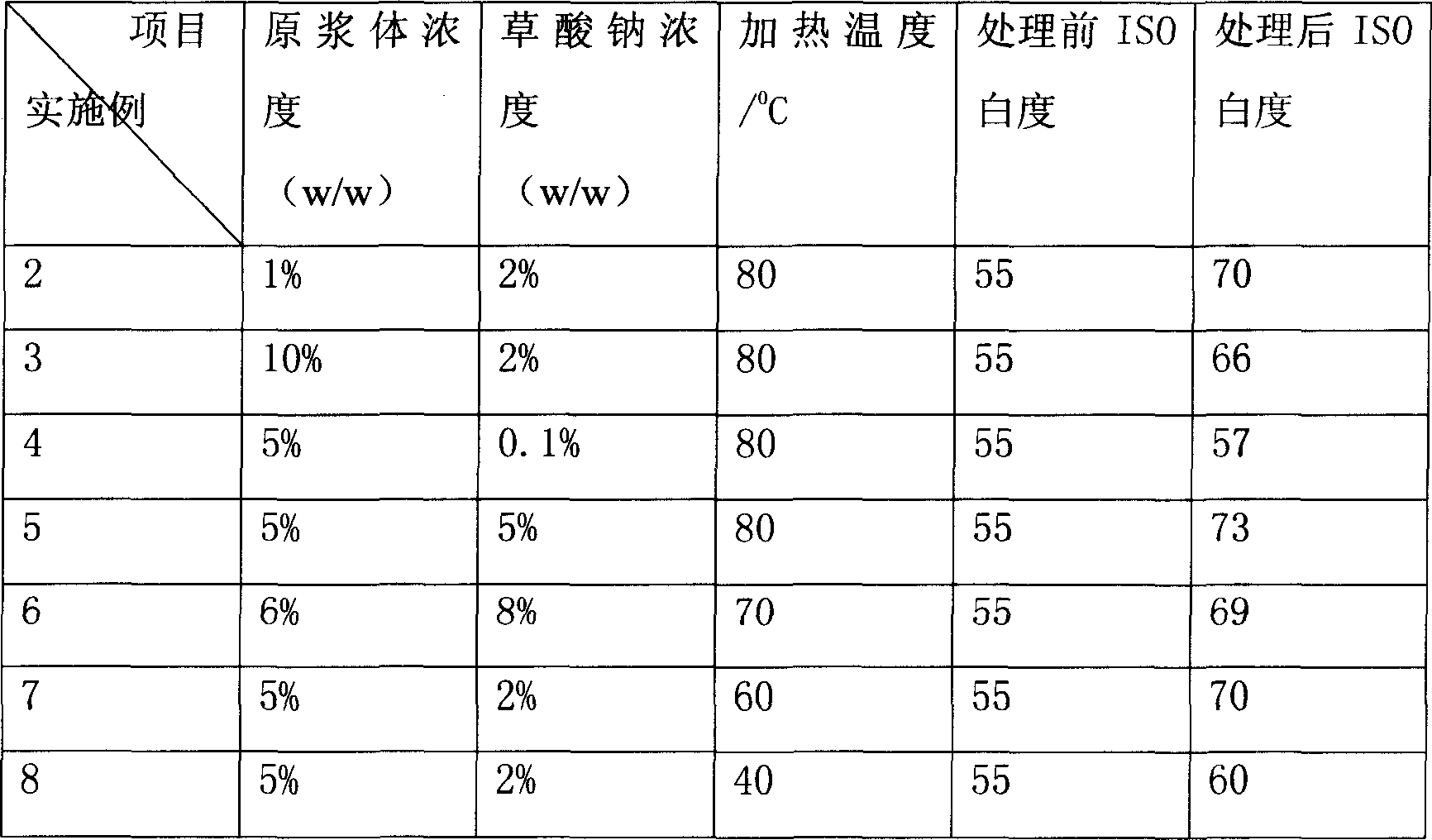

[0030] Press the preparation flow process of embodiment 1, carry out the experiment according to the experimental conditions listed in the table below,

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com