Oil-containing silt plant growing media and method for producing same

A technology of biotechnology and cultivation substrate, applied in:

Topmost field of the present invention, can solve the problems such as high processing cost, limited scope of application, can not reclaim crude oil, reach the effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

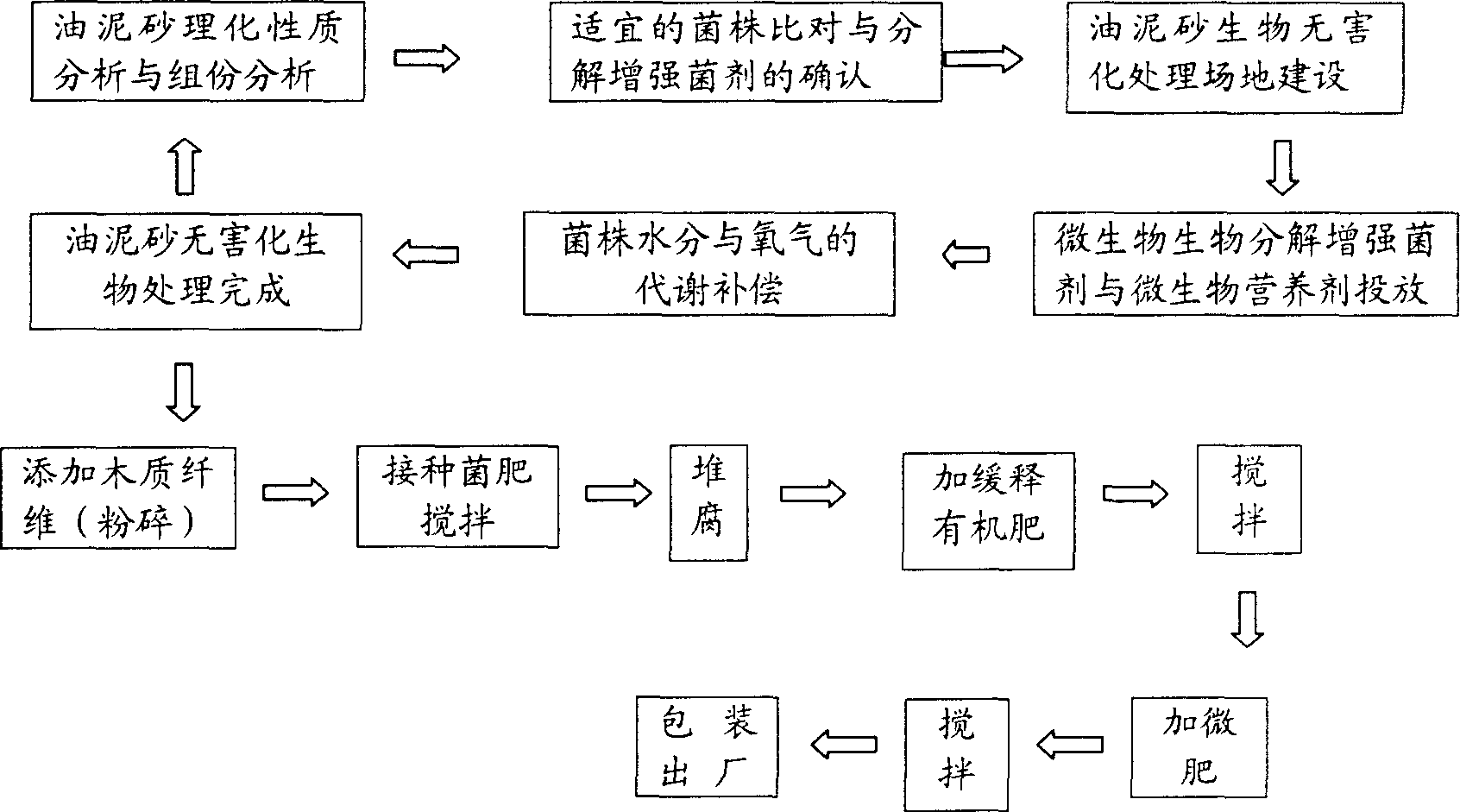

Method used

Image

Examples

example

[0016] Example: Take 100 tons of oil sludge sand, randomly sample 1000 grams per ten tons, and stack them in the open air for ten days. According to the bacterial strains in the oil sludge sand detected in the laboratory, select a suitable microbial decomposition enhancing bacterial agent, add water for aeration, and add biological nutrition Add 10% crushed wood fiber (such as crushed cotton stalks, generally obtained locally), after the inspection reaches the harmless standard of pollutants, mechanically plow and stir, inoculate with 1% bacterial fertilizer, seal and compost After 7 days, add 8% slow-release organic fertilizer, stir, and finally add 1% micro-fertilizer, stir, and pack for delivery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com