Environment-friendly type heat pump mixed working medium

A mixed working fluid, environment-friendly technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of excessive greenhouse effect, high pressure, increased production costs, etc., achieve good environmental performance, reduce filling and filling The effect of improving the energy efficiency ratio

Active Publication Date: 2006-12-27

中化蓝天氟材料有限公司 +2

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] 1) Although R410A and R410A have good heat transfer performance, the pressure is too high under heat pump conditions, even about 50% higher than HCFC-22, and the system requirements are higher than HCFC-22, which will greatly increase production costs

[0007] 2) R407C, although the pressure of R407C is similar to that of HCFC-22, its heat transfer performance is not good. To achieve the same heating capacity, the two devices need to be enlarged, which also increases the production cost, and the temperature glide of R407C is relatively large. System leakage will cause large changes in components, which is not conducive to system maintenance

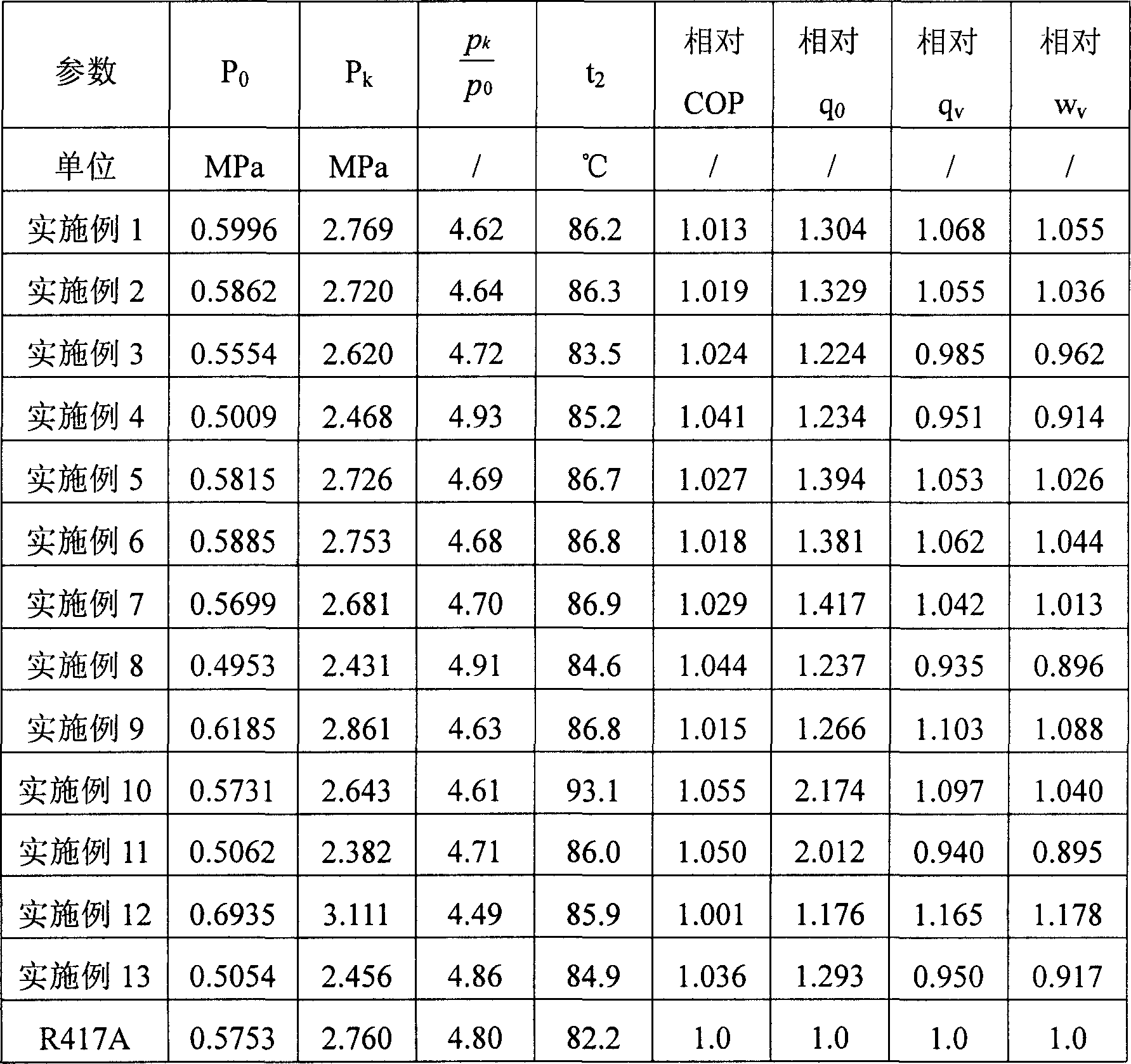

[0009] Although the pressure of R417A is lower than that of HCFC-22 under heat pump conditions, there is no need to improve the system pressure design, but its volumetric heating capacity has dropped too much, and its greenhouse effect is too large, so it still needs to be improved, so it is not HCFC-22. The best alternative working fluid

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0042]Example 1: Physically mix HFC-125, HFC-134a, HFC-161, and HC-600a in a liquid phase at a mass percentage of 30:45:20:5.

Embodiment 2

[0043] Example 2: Physically mix HFC-125, HFC-134a, HFC-161, and HC-600a in a liquid phase at a mass percentage of 25:50:20:5.

Embodiment 3

[0044] Example 3: Physically mix HFC-125, HFC-134a, HFC-152a, and HC-600a in a liquid phase at a mass percentage of 45:20:25:10.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates the environment-friendly type heat pump mixing working fluid, comprising HFC-125, HFC-134a, the third component and forth component. The third component is HFC-161 or HFC-152a, and the forth component is HC-600a or HC-600 or HC-290. The heat pump mixing working fluid meets the environment protection request, has good thermal parameter and thermodynamic property, and can replace the HCFC-22.

Description

technical field [0001] The invention relates to a working medium for completing a thermodynamic cycle in a heat pump system, in particular to an environment-friendly mixed working medium with zero ozone destruction potential. Background technique [0002] As a heat raising device, the heat pump is used to absorb heat from the surrounding environment and transfer it to the object to be heated. According to the principle of reverse Carnot cycle, it is driven by a small part of electric energy to push the compressor to do work on the working medium, so that it absorbs the heat in the surrounding environment in the evaporator, and then releases it for people to use through the condenser. The advantages of heat pumps in terms of energy saving and environmental protection, especially the high economic benefits in the recovery of condensation heat, have attracted people's attention, so there are more and more applications of heat pump equipment with dual fun...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K5/04

Inventor 郭智恺

Owner 中化蓝天氟材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com