Alkaline zinc-based secondary battery negative electrode material and its preparing method

A secondary battery and negative electrode material technology, which is applied in the direction of alkaline battery electrodes, electrode manufacturing, battery electrodes, etc., and can solve the problems of limited battery performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Take 10g ZnO and 2.50g SnCl 2 , the SnCl 2 Dissolve in 10g concentrated HCl, stir until completely dissolved, then dilute with distilled water to make SnCl 2 The concentration is 6.5g / L, add ZnO, stir well, filter, wash with distilled water for 3 times, then vacuum dry at 80°C to get Sn 6 o 4 (OH) 4 Surface modified ZnO zinc-based battery material, Sn 6 o 4 (OH) 4 The weight percent content is 27wt.%.

Embodiment 2

[0013] Take 7g ZnO and 1.00g SnCl 2 , the SnCl 2 Dissolve in 5g concentrated HCl, stir until completely dissolved, then dilute with distilled water to make SnCl 2 The concentration is 3.2g / L, add ZnO, stir well, filter, wash with distilled water for 3 times, then vacuum dry at 80°C to get Sn 6 o 4 (OH) 4 Surface modified ZnO zinc-based battery material, Sn 6 o 4 (OH) 4 The weight percent content is 13wt.%.

Embodiment 3

[0015] Take 6g ZnO and 0.25g SnCl 2 , the SnCl 2 Dissolve in 1.25g concentrated HCl, stir until completely dissolved, then dilute with distilled water to make SnCl 2 The concentration is 0.6g / L, add ZnO, stir well, filter, wash with distilled water for 3 times, then vacuum dry at 80°C to get Sn 6 o 4 (OH) 4 Surface modified ZnO zinc-based battery material, Sn 6 o 4 (OH) 4 The weight percent content is 5wt.%.

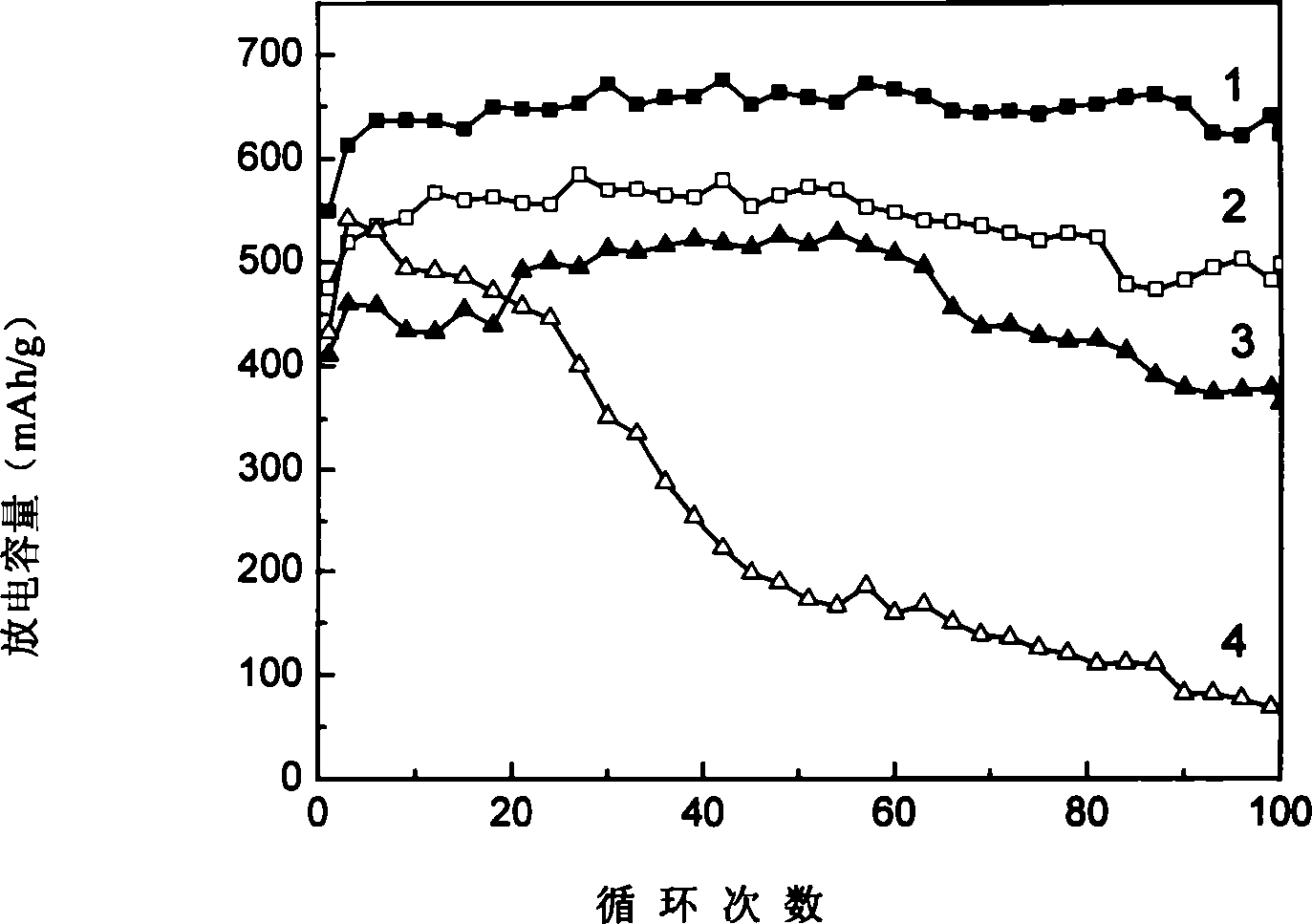

[0016] To make the negative electrode of alkaline zinc-based secondary battery, in Sn 6 o 4 (OH) 4 Add a small amount of CMC and PTFE binders to the surface-modified ZnO negative electrode material, stir it with water evenly, and then coat it on the nickel foam of the current collector. After drying, pressing, and shearing, the size is: 20×20×0.4mm 3 . The positive electrode is Ni(OH) formed by scraping and pressing on nickel foam 2 electrode. The capacity of the positive electrode is three times that of the negative electrode, so that the battery capacity c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com