Solvent for eliminating CO2 from gas mixture

A technology for gas mixture and removal, applied in the fields of chemical separation, air quality improvement, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

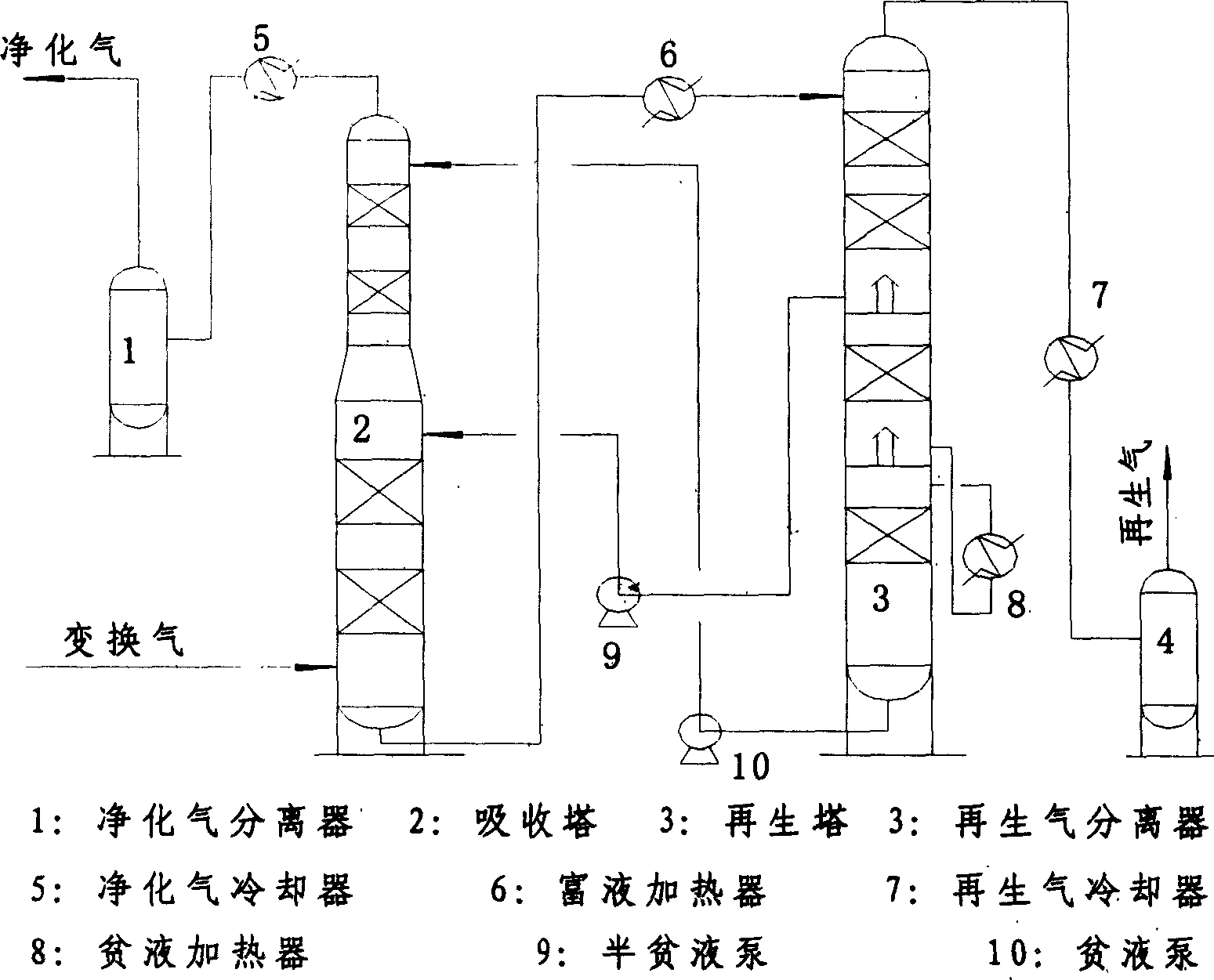

[0014] A CO 2 Mixed gas, CO in the gas 2 The content is 26%, the temperature is normal temperature, the pressure: 0.7MPa, using such as figure 1 Two-stage absorption and two-stage regeneration process.

[0015] regeneration tower temperature

[0016] The running results show that in CO 2 Under the condition of partial pressure of only 0.18MPa, using this solution formula, the solution regeneration temperature is low, and CO can be partially removed without steam regeneration 2 , The purpose of adjusting the product structure, low energy consumption, large operating flexibility.

Embodiment 2

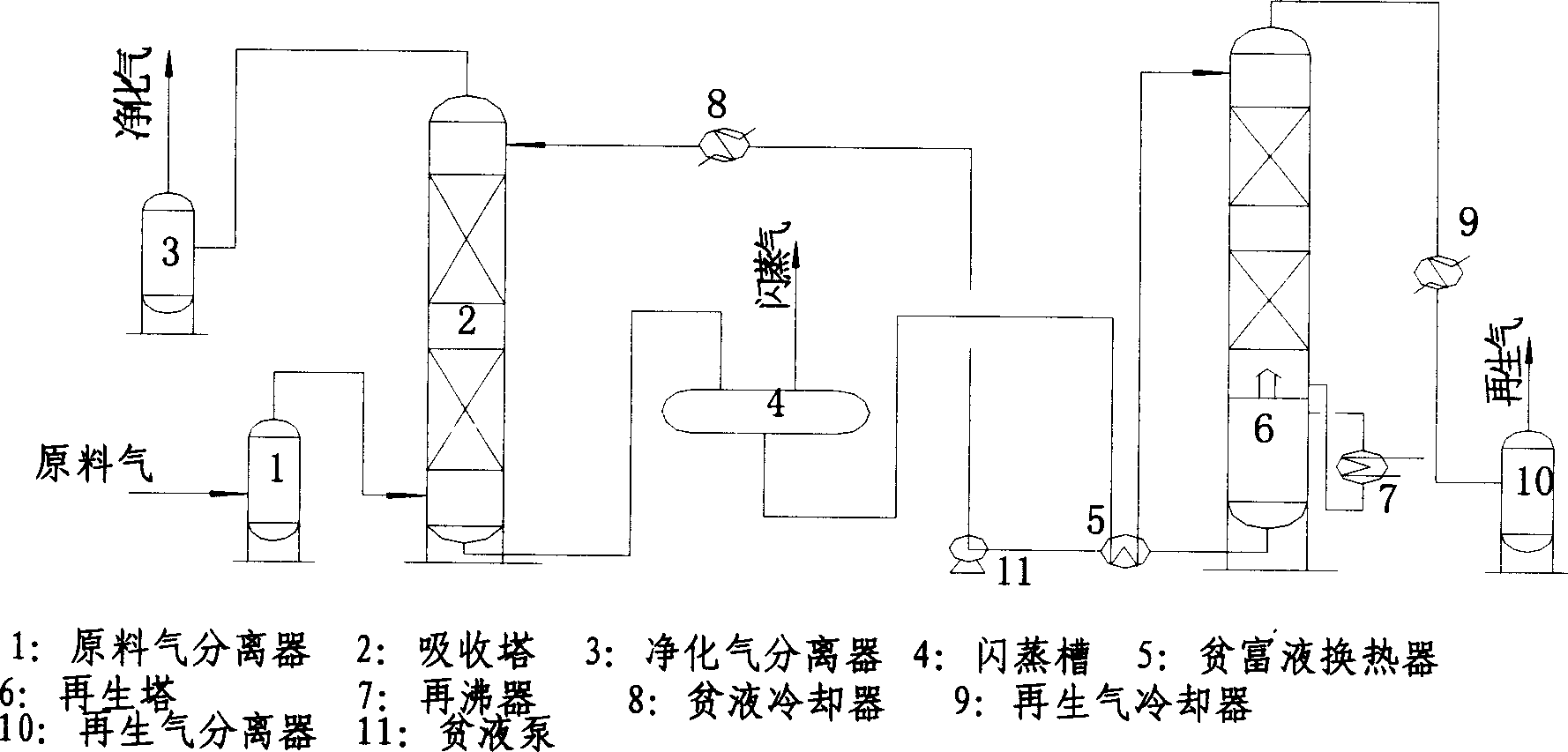

[0019] use as figure 2 The one stage absorption stage regeneration process flow shown.

[0020] project

unit

content

CO 2

mol%

<20ppm

N 2

mol%

0.25

CH 4

mol%

3.57

CO

mol%

29.94

H 2

mol%

65.98

h 2 o

mol%

0.26

flow

N m 3 / h

2.26

temperature

℃

40

pressure

MPaG

2.78

[0021] It can be seen from the production data that the CO in the gas can be purified by using this solution formula 2 The content can be reduced to a very low level, significantly lower than the conventional MDEA decarburization method.

[0022] attached figure 1 It is the two-stage absorption and two-stage regeneration process flow adopted in Example 1.

[0023] attached figure 2 It is the one-stage absorption and one-stage regeneration process flow adopted in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com