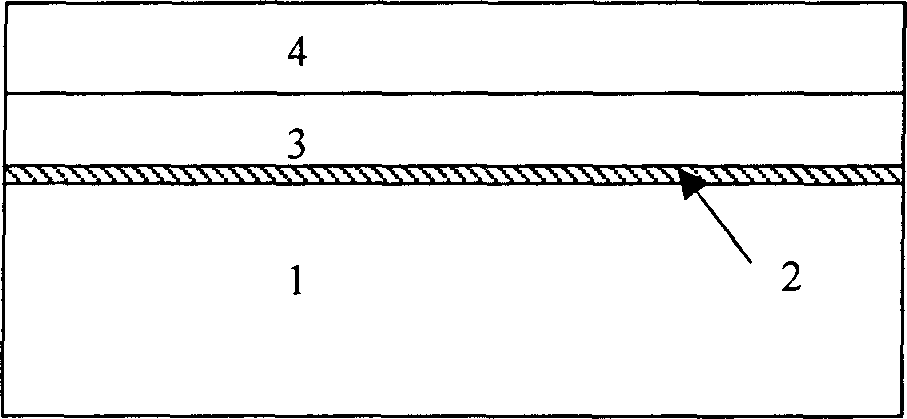

Self-cleaning household appliance glass capable of shielding electromagnetic radiation and its prepn

A self-cleaning, electromagnetic wave technology, applied in the field of home-coated glass and its preparation, to achieve the effects of light weight, elimination of condensation, and strong chemical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Using ordinary white glass as the substrate material, the substrate is cleaned by conventional chemicals, filtered and washed with deionized water, placed on the roller conveying device, dried and sent to a fully enclosed tunnel multi-step coating studio (Background vacuum degree 3×10 -3 Pa) start to deposit thin films sequentially. In the first studio, RF-PECVD is used to deposit silicon oxide on the substrate. First, the substrate is plasma-bombarded in a nitrogen atmosphere for 10 minutes, and then the substrate is heated to 250 ° C. The reaction pressure is 40 Pa, and the reaction source gas is diluted with nitrogen. After the concentration of 5-15% silane SiH 4 and diluted with nitrogen to a concentration of 5-15% nitrous oxide N 2 O, SiH 4 :N 2 The flow ratio of O is 1:1.1.

[0025] 2) Transfer the glass on which the silicon oxide film has been deposited to the second working room with a background vacuum of 3×10 -3 Pa, Sb-doped SnO deposited by MO-PECVD ...

Embodiment 2

[0029]1) Using ordinary white glass as the substrate material, the substrate is cleaned by conventional chemicals, filtered and washed with deionized water, placed on the roller conveying device, dried and sent to a fully enclosed tunnel multi-step coating studio (Background vacuum degree 3×10 -3 Pa) start to deposit thin films sequentially. In the first studio, RF-PECVD is used to deposit silicon oxide on the substrate. First, the substrate is plasma-bombarded in a nitrogen atmosphere for 10 minutes, and then the substrate is heated to 250 ° C. The reaction pressure is 40 Pa, and the reaction source gas is diluted with nitrogen. After the concentration of 5-15% silane SiH 4 and diluted with nitrogen to a concentration of 5-15% nitrous oxide N 2 O, SiH 4 :N 2 The flow ratio of O is 1:1.2.

[0030] 2) Transfer the glass coated with silicon oxide film to the second working room, the background vacuum degree is 3×10 -3 Pa, Sb-doped SnO deposited by MO-PECVD 2 Thin film, ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com