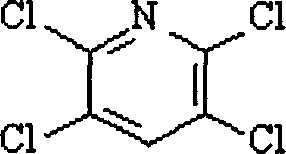

One-step process for producing tetrachloropyridine in high content

A technology of tetrachloropyridine and pyridine, which is applied in the field of one-step production of tetrachloropyridine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

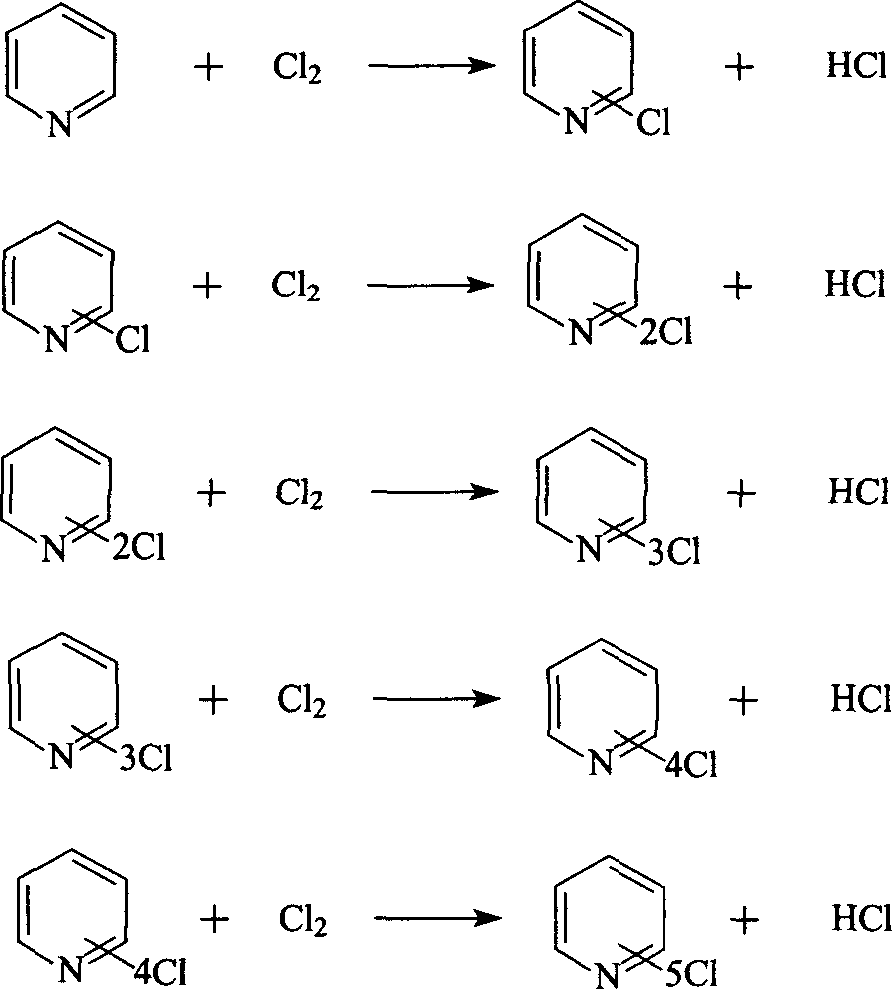

Method used

Image

Examples

Embodiment 1

[0011] Load the catalyst 2% FeCl in the reaction tube 3 -3% CuCl 2 -6% BaCl 2 / C 35g (the content of the active ingredient is the mass percentage, the same below), feed nitrogen, and adjust the gas space velocity to 500h -1 , heat the temperature of the reaction tube to 380°C and keep it warm for 1.5h, then heat the reaction tube to 390°C, pass in chlorine gas to activate the catalyst, raise the temperature of the reaction tube to 420°C after 1h, and preheat and vaporize the pyridine Add the reaction tube with a metering pump to make it react with chlorine gas. The preheating temperature of pyridine is 160° C., n (pyridine): n (nitrogen): n (chlorine)=1:8:12. The reaction product was directly cooled to a white solid powder. The product is analyzed by high-performance liquid chromatography. The mass percentage of pentachloropyridine is 11-12%, 2,3,5,6-tetrachloropyridine is 87-88%, and there are about 0.5% trichloropyridine and dichloropyridine Chloropyridine, no raw mater...

Embodiment 2

[0013] Load the catalyst 1% AlCl in the reaction tube 3 -3% FeCl 3 -4% CuCl 2 -5% BaCl 2 / C 35g, feed nitrogen, adjust the gas space velocity to 800h -1 , heat the temperature of the reaction tube to 400°C and keep it warm for 1 hour, then pass chlorine gas at 400°C to activate the catalyst, after 1.5 hours, lower the temperature of the reaction tube to 390°C, and add the preheated vaporized pyridine to the reaction with a metering pump The tube is mixed with chlorine gas for reaction, wherein the preheating temperature of pyridine is 170° C., n (pyridine): n (nitrogen): n (chlorine) = 1:6:10. The reaction product was directly cooled to a white solid powder. The product is analyzed by high-performance liquid chromatography. The mass percentage of pentachloropyridine is 8.5-9.5%, 2,3,5,6-tetrachloropyridine is 90-91%, and there are about 0.5% trichloropyridine and dichloropyridine. Chloropyridine, no raw material pyridine remains. Afterwards, the preheated and vaporized p...

Embodiment 3

[0015] Load the catalyst 5% FeCl in the reaction tube 3 -4%AlCl 3 -4% BaCl 2 / C 35g, feed nitrogen, adjust the gas space velocity to 1000h -1 , heat the reaction tube temperature to 370°C and keep it warm for 1h, then heat the reaction tube to 380°C and pass chlorine gas to activate the catalyst, after 1h, lower the temperature of the reaction tube to 350°C, and measure the preheated and vaporized pyridine The pump is added to the reaction tube to mix with chlorine gas for reaction, wherein the preheating temperature of pyridine is 160°C, n (pyridine): n (nitrogen): n (chlorine) = 1:7:8.5, and the reaction product is directly cooled to a white solid powder . The product is analyzed by high-performance liquid chromatography. The mass percent content of pentachloropyridine is 4-5.5%, 2,3,5,6-tetrachloropyridine is 93-94%, and there are about 2-6% trichloropyridine And dichloropyridine, pyridine remains about 1%. Afterwards, the preheated and vaporized pyridine is continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com