A novel linear low-density polyethylene for urea tank and its preparation method

A linear low-density, urea tank technology, applied in the field of polymer materials, can solve the problems of low melting point, lack of mechanical properties, sticking kettle phenomenon, etc., and achieve the effects of large specific surface area, high accessibility and excellent copolymerization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

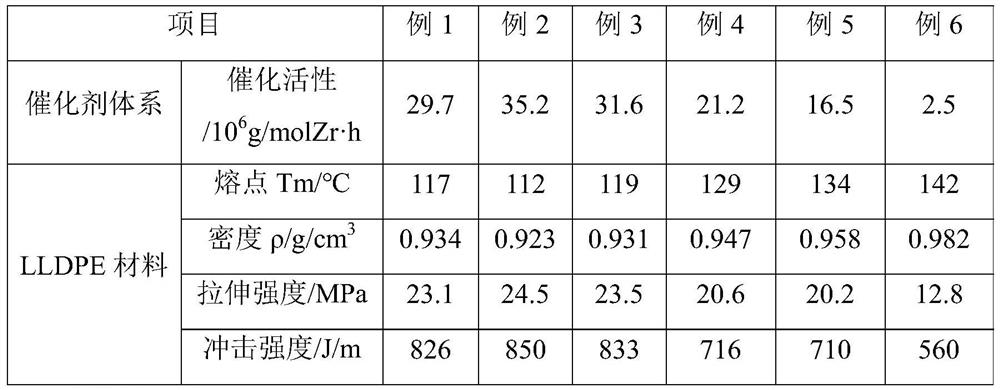

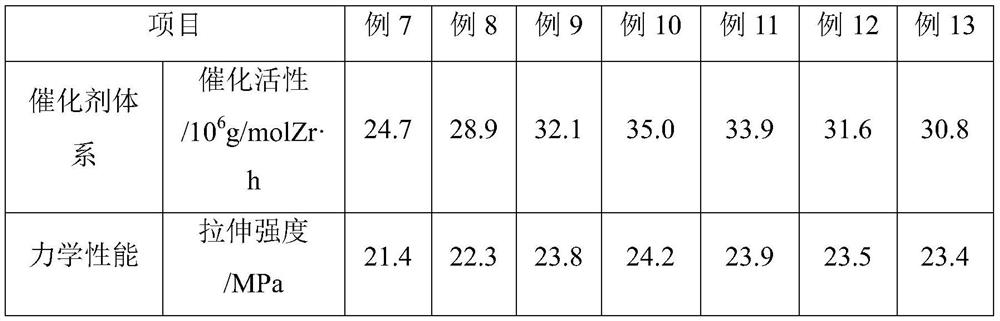

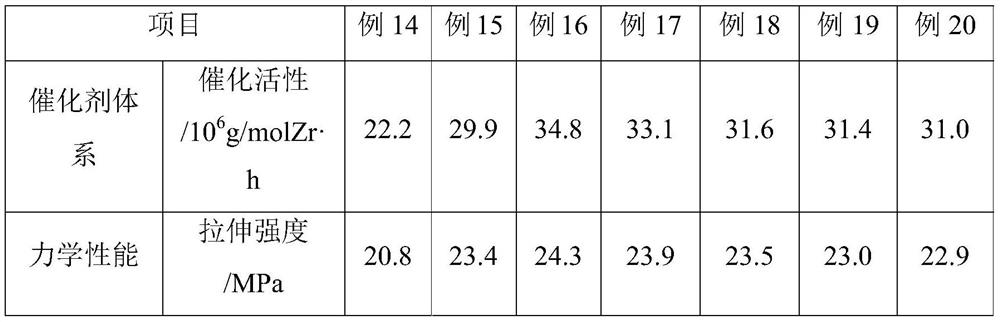

Examples

Embodiment 1

[0036] The specific preparation method of metal organic framework material MIL-100 is as follows:

[0037] Dissolve 2.7g of ferric chloride hexahydrate in 50mL of deionized water, stir to fully dissolve, then add 1.39g of trimesic acid, and continue to stir for 0.5h; then put the above solution into an autoclave at 130°C for 72h; after the reaction is completed Cool to room temperature, wash with hot water and methanol three times, cook in boiling methanol for 12 hours, and vacuum dry at 150°C for 12 hours to obtain metal organic framework material MIL-100.

[0038] The oligomerization catalyst is a metal-organic framework material / Fe(Salen) heterogeneous catalyst, and its specific preparation method is as follows:

[0039] After the metal organic framework material was mixed with absolute ethanol to prepare a suspension with a mass fraction of 30%, salicylaldehyde was added thereto, and stirred for 30 minutes under the condition of 1000r / min, wherein the amount of salicylalde...

Embodiment 2

[0050] The preparation method of the metal organic framework material MIL-100 is the same as that in Example 1.

[0051] The oligomerization catalyst is a metal-organic framework material / Fe(Salen) heterogeneous catalyst, and its specific preparation method is as follows:

[0052] After mixing the metal organic framework material and absolute ethanol to prepare a suspension with a mass fraction of 60%, add salicylaldehyde to it, and stir for 10 minutes under the condition of 2500r / min, wherein the amount of salicylaldehyde added accounted for the metal organic framework 80% of the material mass;

[0053] Add ethylenediamine to the above mixed solution, heat to 80°C and react at 1500r / min for 1h, wherein the molar ratio of salicylaldehyde to ethylenediamine is 3:1;

[0054] The reaction solution obtained above was cooled to room temperature and vacuum filtered, the filter cake was dried in a drying oven at 80° C. for 6 hours, and the dried filter cake was pulverized to obtain ...

Embodiment 3

[0063] The preparation method of the metal organic framework material MIL-100 is the same as that in Example 1.

[0064] The oligomerization catalyst is a metal-organic framework material / Fe(Salen) heterogeneous catalyst, and its specific preparation method is as follows:

[0065] After mixing the metal-organic framework material and absolute ethanol to prepare a suspension with a mass fraction of 60%, add salicylaldehyde to it, and stir for 130min under the condition of 2500r / min, wherein the amount of salicylaldehyde added accounted for 60% of the metal-organic framework 80% of the material mass;

[0066] Add ethylenediamine to the above mixed solution, heat to 80°C and react at 1500r / min for 1h, wherein the molar ratio of salicylaldehyde to ethylenediamine is 3:1;

[0067] The reaction solution obtained above was cooled to room temperature and vacuum filtered, the filter cake was dried in a drying oven at 80° C. for 6 hours, and the dried filter cake was pulverized to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com