Structural layer for playground track and materials used for track pavings

A technology for structural layers and sports fields, applied in the directions of roads, pavements, roads, etc., can solve the problems of hazards, poor elasticity, and easy accumulation of water for athletes, and achieve the effect of no environmental pollution, good drainage function, and not easy to accumulate water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

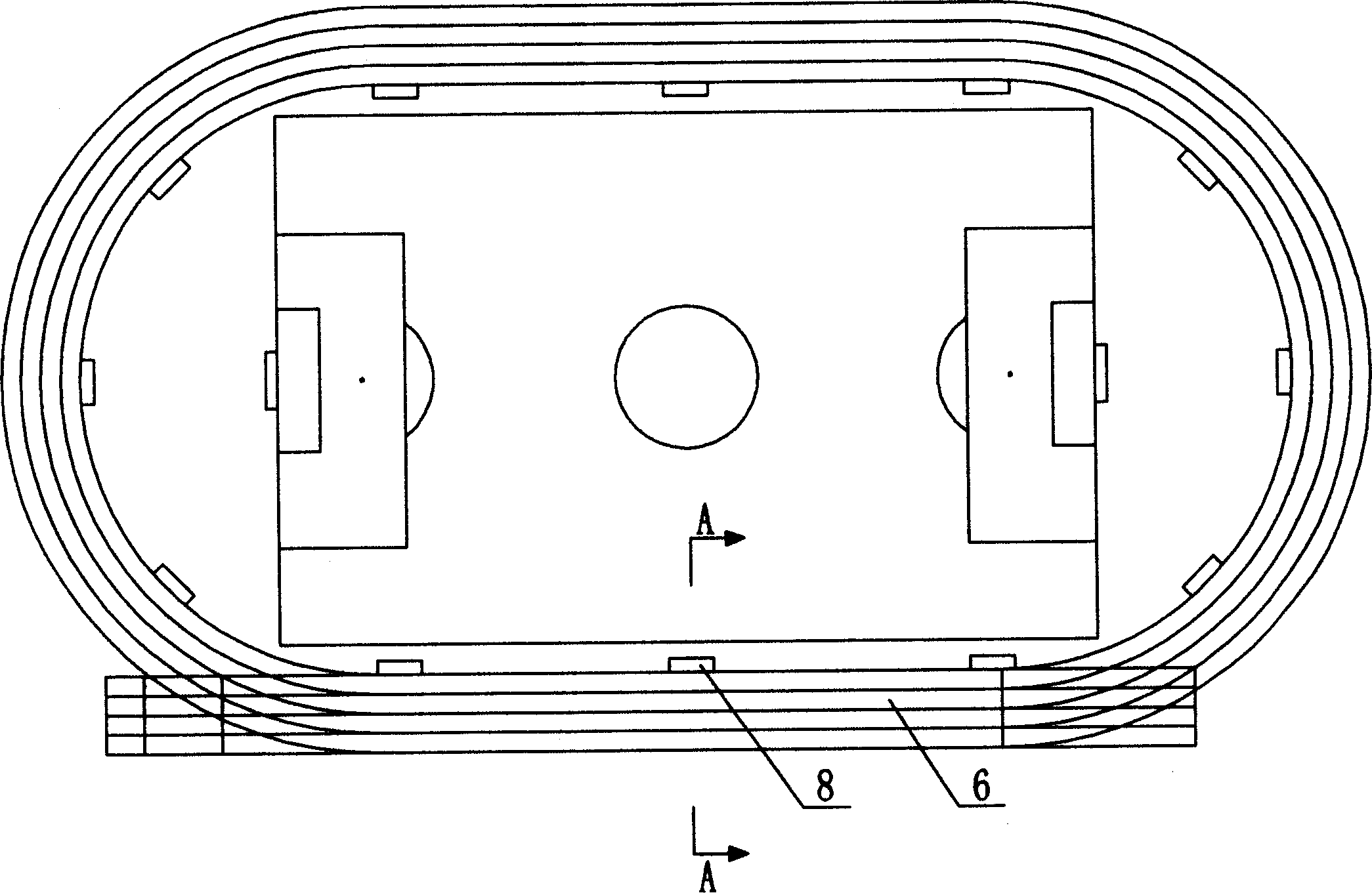

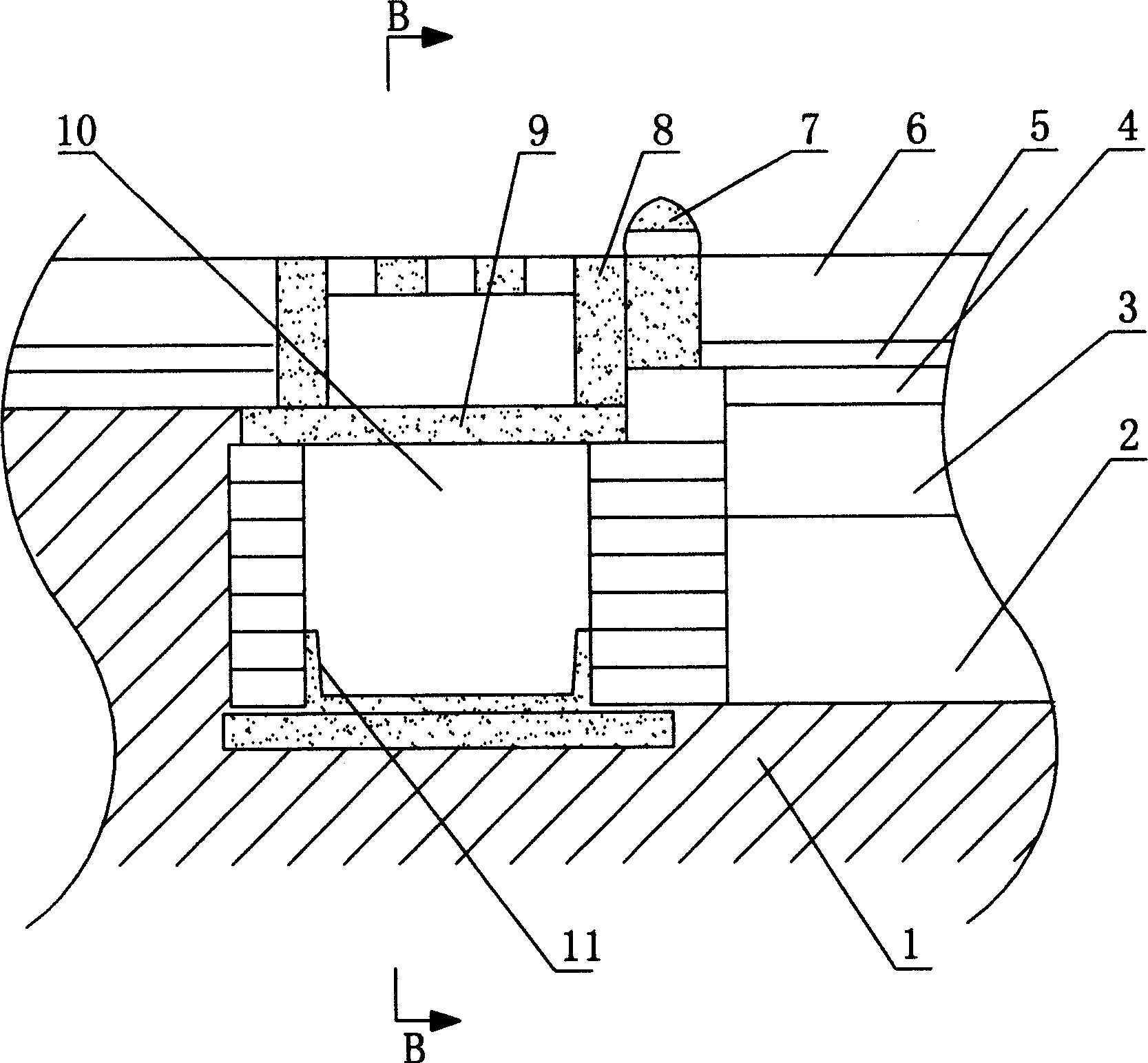

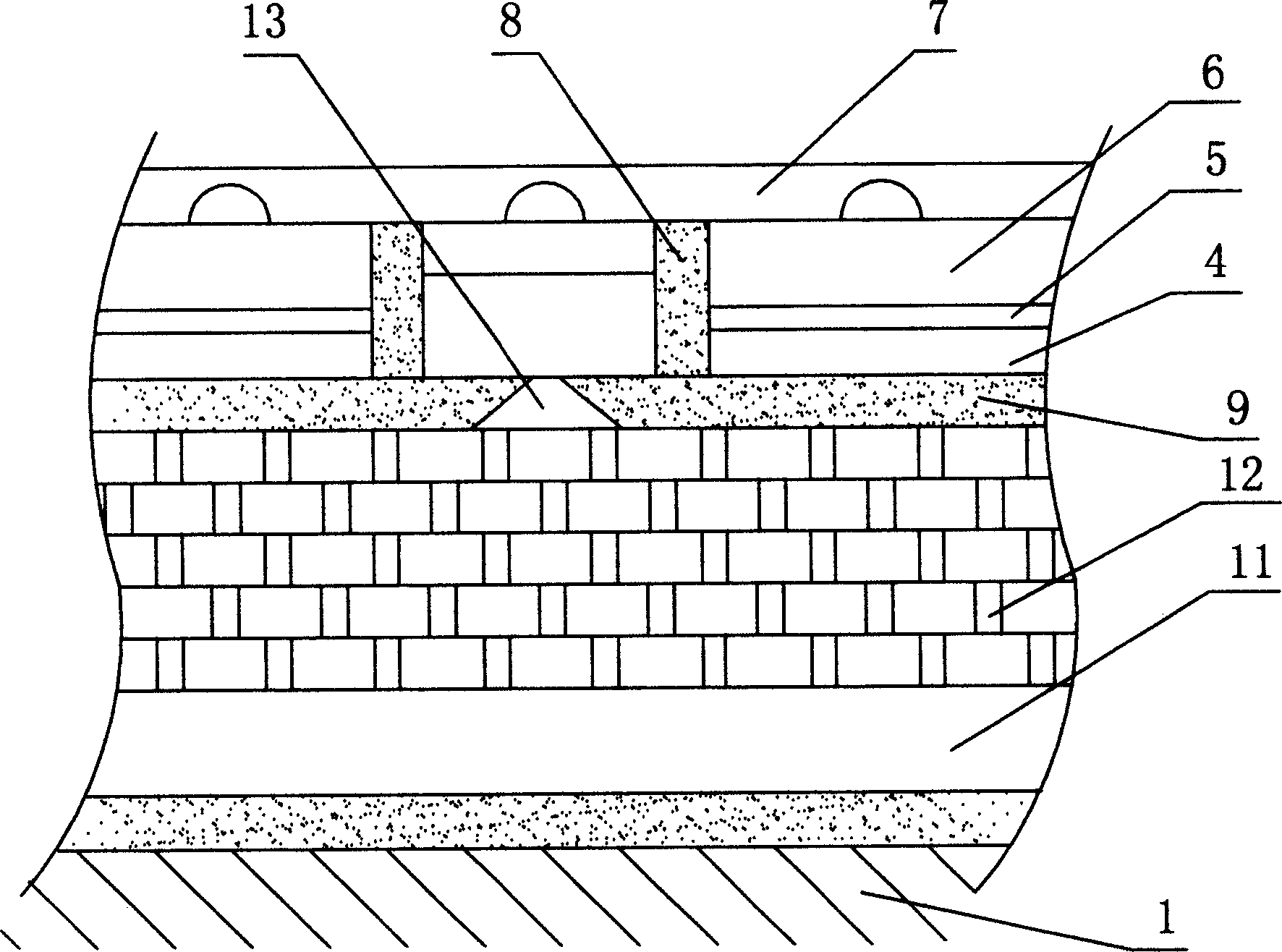

[0024] On top of the foundation stratum 1 that is sloped at 5 / 1000, there are flake layer 2 and leveled and compacted crushed stone layer 3 from bottom to top, and the particle size of the crushed stone is 20-40mm. On top of the crushed stone layer, a layer of charcoal slag with a particle size of 0.5-5 mm and a compacted thickness of 40-70 mm is dry-laid 4, and on the top of the charcoal slag layer, a layer of wet grass with a thickness of 5-7 mm is spread. 5. It is better to use straw or wheat straw as the grass in the grass layer. A 70-130 mm red brick slag-sawdust runway surface layer 6 is paved on the grass layer, and the weight percentage of each material of the red brick slag-sawdust runway surface layer is: fine red bricks with a particle size of 1-5 mm 60% to 80% of slag, 7% to 10% of sawdust, 7% to 12% of quicklime powder of 80 to 130 mesh; shale powder of 80 to 130 mesh is the balance; after mixing these materials with water and stirring evenly, pouring and laying o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com