Halogenated cyclic sulfite, and an electrolyte, lithium cell and lithium-sulfar cell

A cyclic sulfite, halogenated vinyl sulfite technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low discharge capacity, low cycle capacity, poor storage performance of lithium-sulfur batteries, etc. To achieve the effect of increasing the decomposition voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Synthesis of halogenated cyclic sulfites:

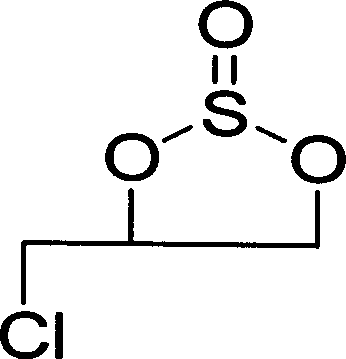

[0054] refer to figure 1 , taking 1-chloropropylene sulfite (ClPS) as an example:

[0055] 101.0 grams of triethylamine, 84.9 grams of dichloromethane and 110.5 grams of 3-chloro-1,2-propanediol are placed in a glass container with a volume of 1000 mL and mixed evenly, 119 grams of thionyl chloride and 84.9 grams of dichloromethane The mixture was added dropwise to the container, and the dropwise addition process continued for 3 hours while stirring the contents of the container. After the dropwise addition, the reaction system was heated to 65° C. and kept for 2 hours.

[0056] The reaction mixture was filtered under normal pressure, and the filtrate was distilled under normal pressure at 60°C until no distillate flowed out of the filtrate. After the above operations, the remaining liquid obtained was the crude product of 1-chloropropylene sulfite. The crude product was Dehydration was performed using a total reflux dehydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com