Method for nano zinc oxide crystal surface controllable growth

A nano-zinc oxide, crystal face technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of limitation, cumbersome operation process, harsh reaction conditions, etc., to achieve no vapor pressure, high reaction efficiency, decomposition The effect of high voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) In a glass test tube about 42cm long, mix 1.6ml ethylenediamine and 2.2ml oleic acid evenly to obtain an orange-yellow transparent liquid, and then add 0.24g anhydrous zinc acetate.

[0019] (2) Insert the glass test tube vertically into the tube furnace and put it on the thermocouple. After 5 minutes, it was heated to 270°C and kept at a constant temperature for 20 minutes.

[0020] (3) After cooling to room temperature, the glass tube was taken out and the upper layer of orange-yellow solution was poured out, and the lower layer of light-yellow precipitate was repeatedly washed with n-hexane and ethanol for 10 times, and the final product was dispersed in ethanol.

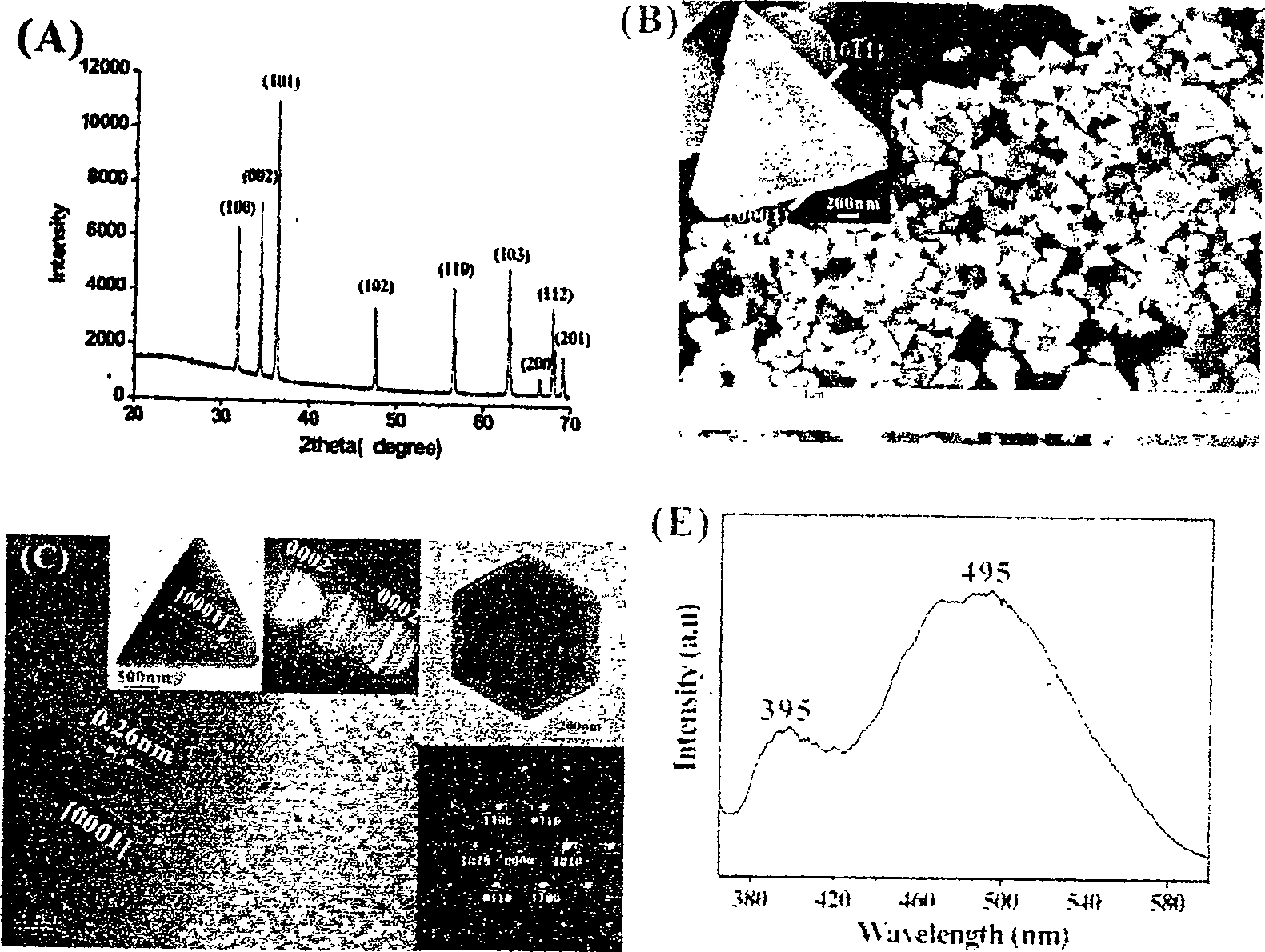

[0021] The morphology, composition and microstructure of the product are systematically studied by XRD, SEM, TEM, HRTEM and other modern nano-testing and analysis techniques. XRD characterizes pure wurtzite ZnO as figure 1 As shown in (A), the unit cell parameters are a=3.25A, c=5.21A, and the space ...

Embodiment 2

[0023] (1) In a glass test tube about 42cm long, mix 0.8ml ethylenediamine and 1.1ml oleic acid evenly to obtain an orange-yellow transparent liquid, and then add 0.24g anhydrous zinc acetate.

[0024] (2) Insert the glass test tube vertically into the tube furnace and put it on the thermocouple. After 10 minutes, it was heated to 286°C and kept at a constant temperature for 40 minutes.

[0025] (3) After the reaction was completed, the glass tube was taken out and the upper layer of the orange-yellow solution was poured out, and the lower layer of the light-yellow precipitate was repeatedly washed with n-hexane and ethanol for 10 times, and the final product was dispersed in ethanol.

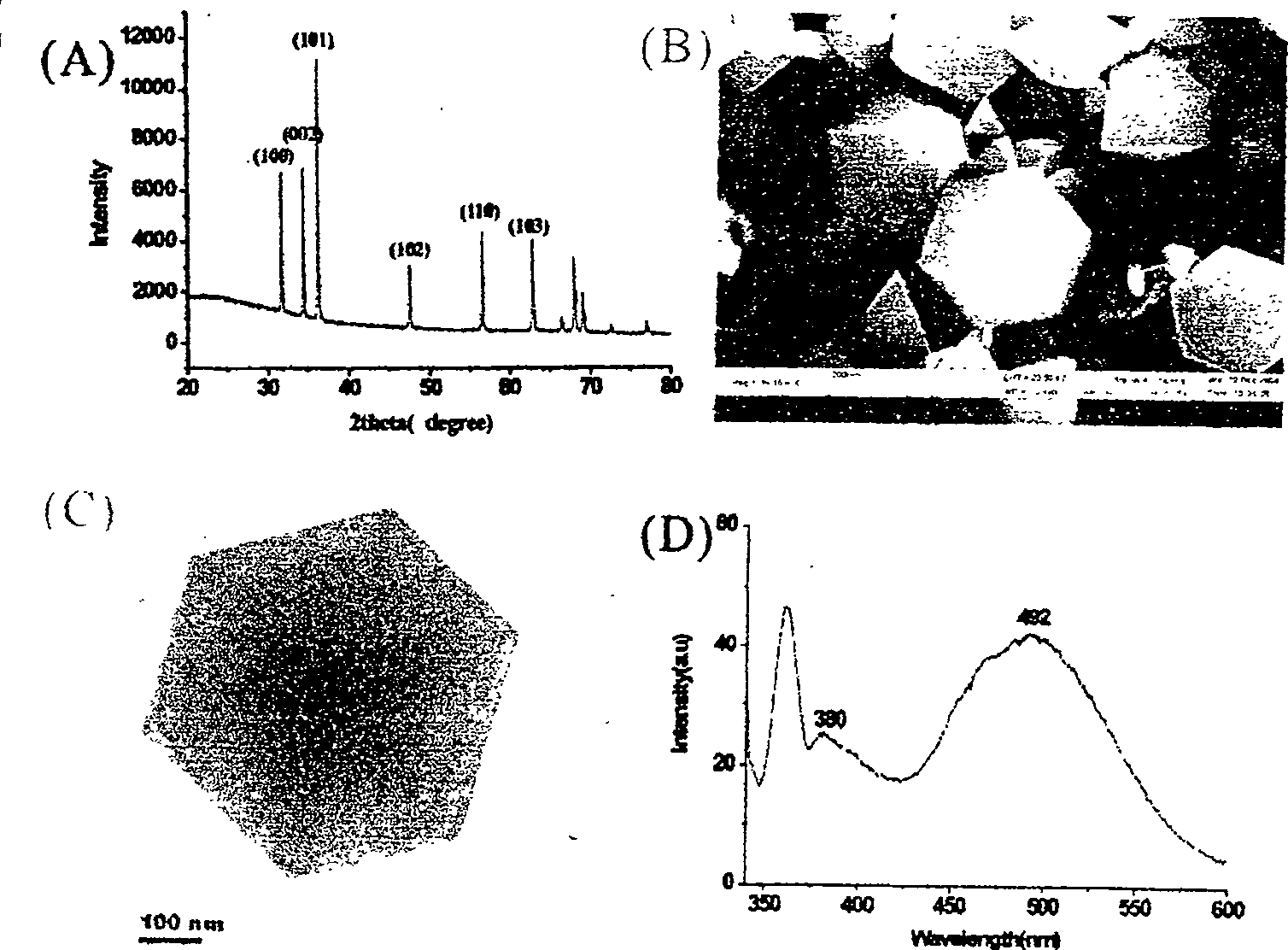

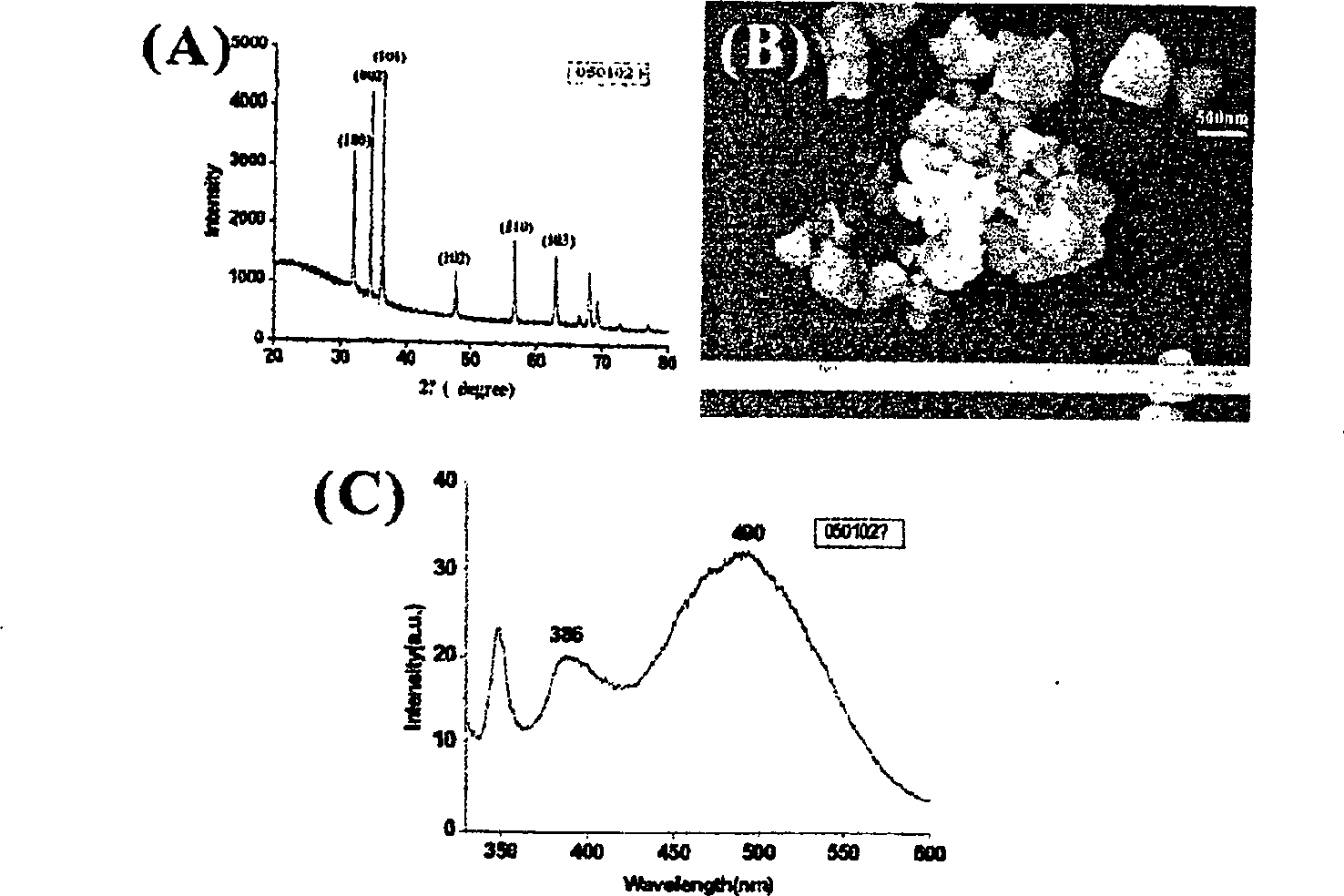

[0026] The product is characterized by XRD, SEM, and TEM as a ZnO hexagonal pyramid structure, and the diameter and height of the bottom surface are both 1-1.5 μm. The bottom surface is a (0001) polar surface, and the side surface is a {1011} polar surface. PL shows a very strong fluorescence...

Embodiment 3

[0028] (1) In a glass test tube about 42cm long, mix 0.8ml ethylenediamine and 1.1ml oleic acid evenly to obtain an orange-yellow transparent liquid, and then add 0.24g anhydrous zinc acetate.

[0029] (2) Insert the glass test tube vertically into the tube furnace and put it on the thermocouple. After 15 minutes, it was heated to 286°C and kept at a constant temperature for 2 hours.

[0030] (3) After the reaction is completed, take out the glass tube and pour out the reddish-brown solution in the upper layer, and wash the light yellow precipitate in the lower layer with n-hexane and ethanol repeatedly for 10 times, and finally the product is dispersed in ethanol.

[0031] The product is characterized by XRD, SEM, and TEM as a ZnO hexagonal pyramid structure, and the diameter and height of the bottom surface are both 1-1.5 μm. The bottom surface is a (0001) polar surface, and the side surface is a {1011} polar surface. PL shows a very strong fluorescence emission in the green...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com