Bi-polar composite electrode for electrolyzing aluminum

A compound electrode and bipolar technology, which is applied in the field of aluminum electrolysis, can solve problems such as corrosion, affecting connections, and speeding up connections, so as to achieve the effects of reducing production costs, convenient operation, and slowing down corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

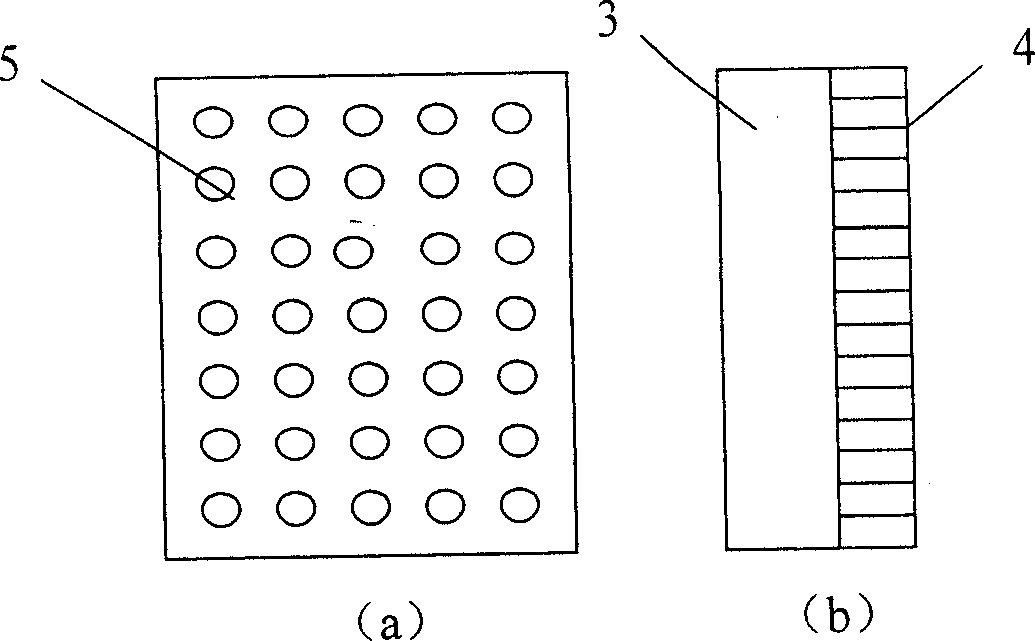

[0023] Composite electrode structure such as image 3 . The thickness of the anode layer is 50mm, and the thickness of the cathode layer is 50mm. The anode layer and the cathode layer are connected by stacking or bonding, the cathode pore diameter is 5mm, and the pore area accounts for 50% of the electrode area. The wettable cathode layer is made of TiB 2 Preparation, the inert anode layer is prepared from an alloy of Ni 60%, Fe 22%, Al 8%, Cu 10% by mass percentage.

Embodiment 2

[0025] Composite electrode structure such as image 3 . The thickness of the anode layer is 5mm, and the thickness of the cathode layer is 5mm. The anode layer and the cathode layer are connected by stacking or bonding, the cathode aperture is 10mm, and the pore area accounts for 80% of the electrode area. The wettable cathode layer is made of ZrB 2 Preparation, the inert anode layer is prepared from an alloy of Ni 52%, Fe 30%, Al 10%, Cu 8% by mass percentage.

Embodiment 3

[0027] Composite electrode structure such as image 3 . The thickness of the anode layer is 200mm, and the thickness of the cathode layer is 200mm. The anode layer and the cathode layer are connected by stacking or bonding, the cathode aperture is 1mm, and the pore area accounts for 20% of the electrode area. The wettable cathode layer is made of TiB 2 -C (mass percentage TiB 2 55%) composite material, and the inert anode layer is prepared from an alloy of Ni 70%, Fe 10%, Al 10%, and Cu 10% by mass percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com