Process for united repairing heavy metal polluted soil by electric power and iron permeable reaction lattices

A technology of combined restoration of contaminated soil, applied in the restoration of contaminated soil, etc., can solve problems such as poor soil fluidity, and achieve the effect of avoiding secondary pollution and reducing changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

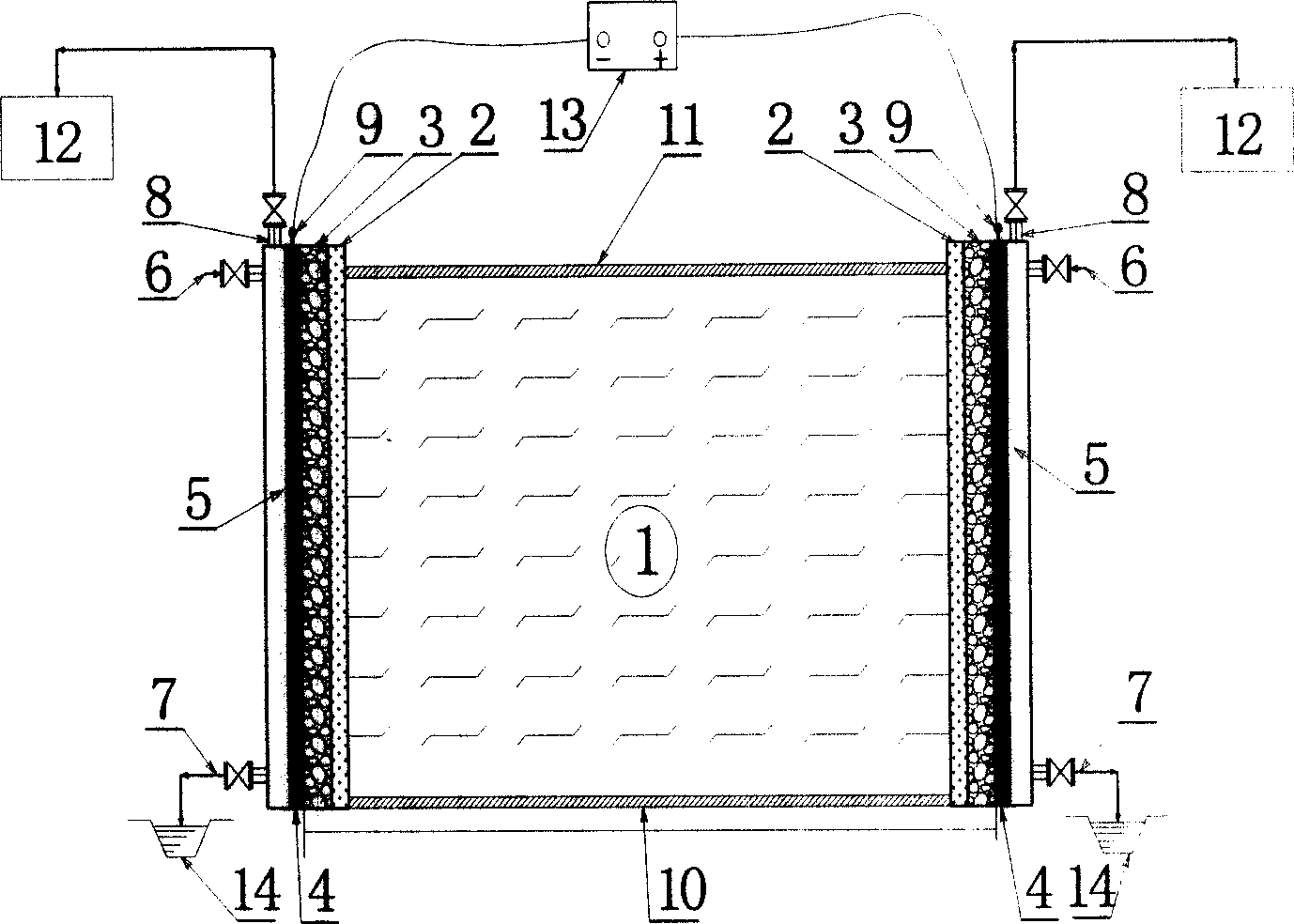

[0020] Potassium dichromate (K 2 Cr 2 o 7 ) to make unpolluted soil (chromium background value 92mg / kg) into polluted soil containing chromium (VI) 1000mg / kg, using electric power and iron PRB combined technology such as figure 1 The device is repaired, and a layer of anti-seepage layer 10 is tiled under the polluted soil 1, and sand 2 is vertically placed on both sides of the chromium-contaminated soil, followed by iron walls (PRB) 3 and electrodes 4 . The electrode chamber 5 is filled with water from the water inlet 6 and discharged from the water outlet 7. The water intake and drainage are all controlled by the water valve. The waste gas generated in the electrode chamber 5 is controlled by the air valve, and is transported to the waste gas treatment pool 12 through the exhaust port 8 for treatment. emission. The electrode 4 is connected with the anode output and the cathode output port of the DC transformer 13 through the terminal 9 . In order to ensure the moisture co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com